Technical and instalation

manual FLOW 38 Batch Page 17 (of 49) COMAC CAL

s.r.o.

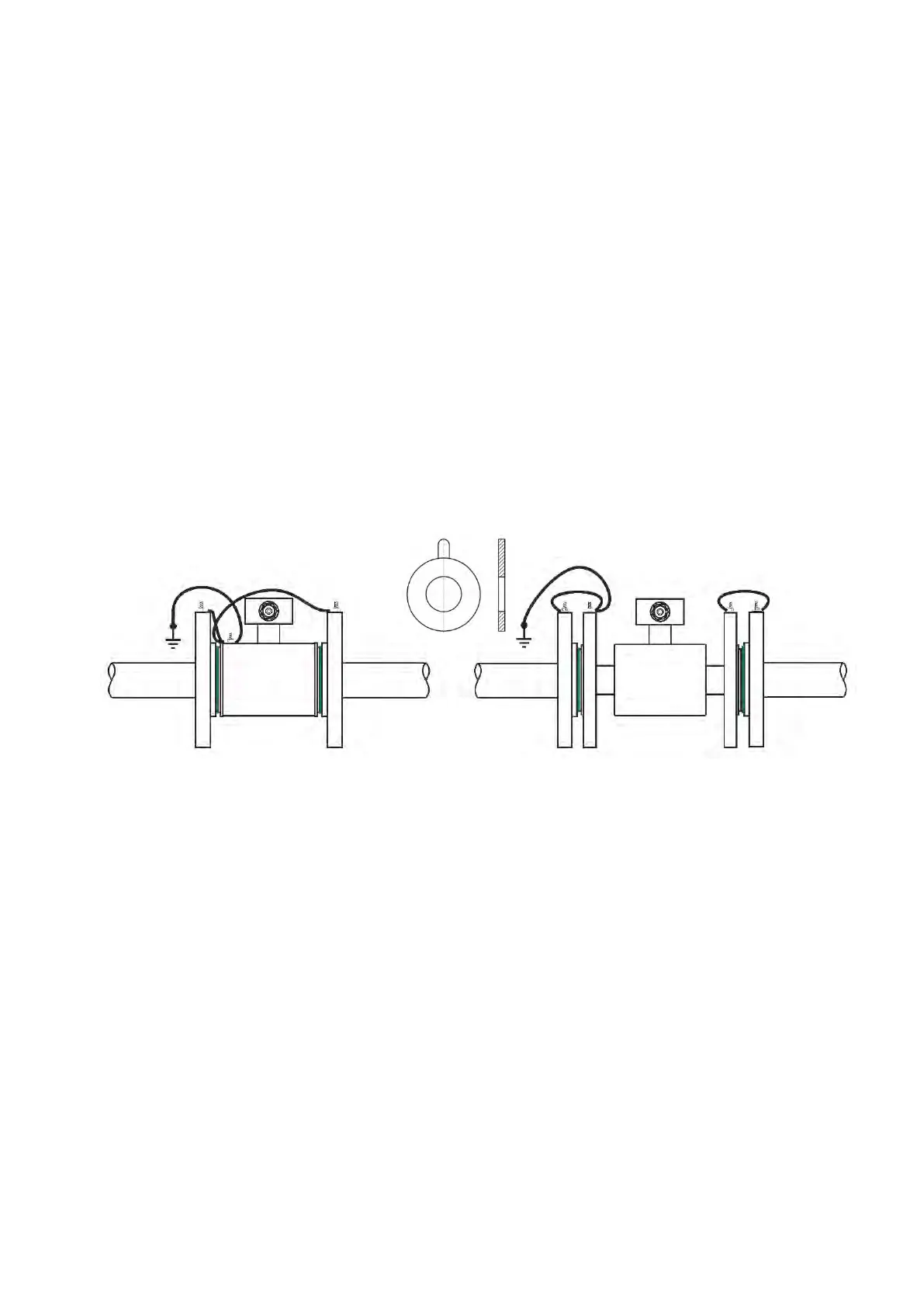

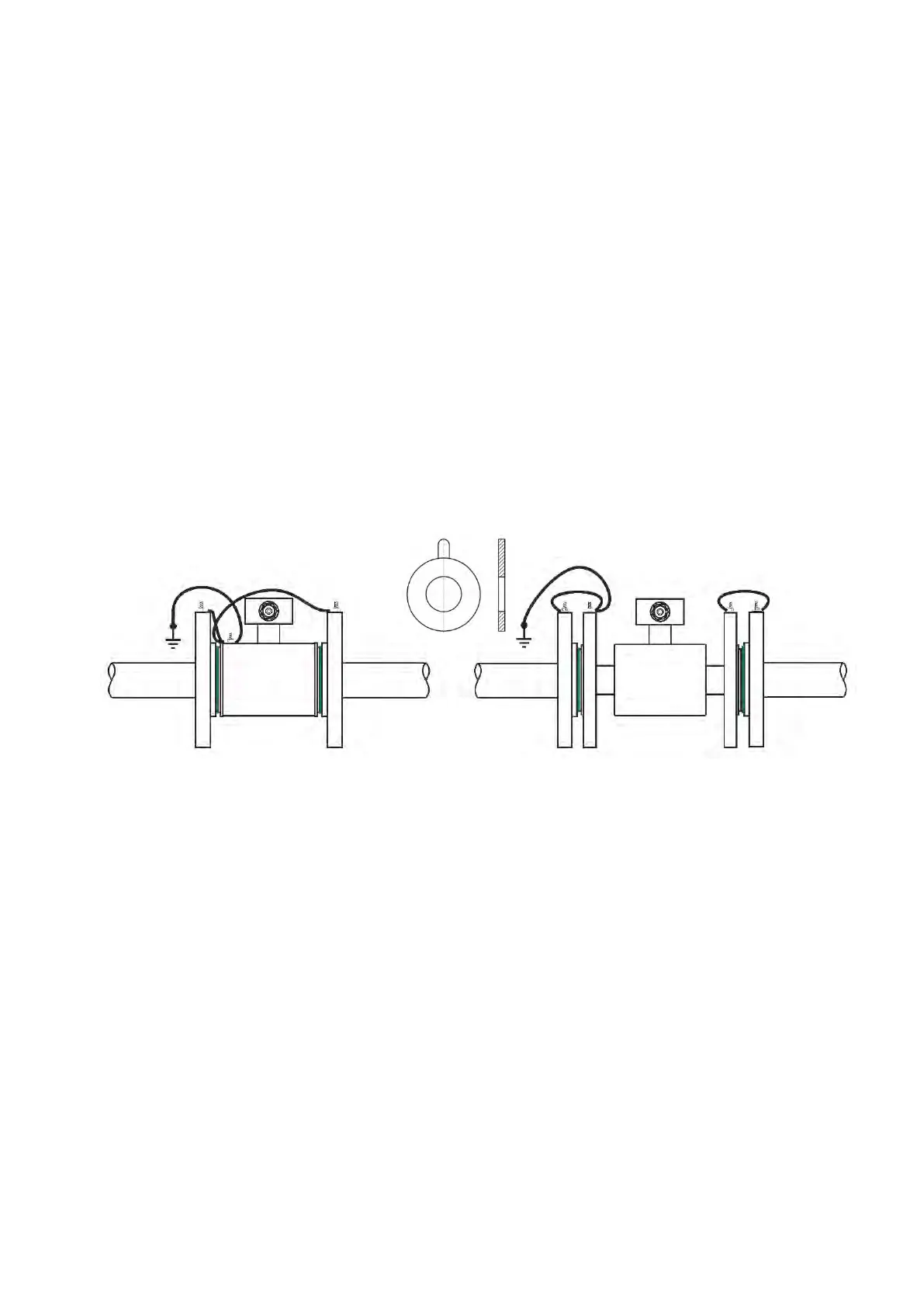

Earthing rings

Using for a plastic pipeline or in case of metallic pipelines with internal plastic lining turned up or

pulled out to the front faces of the pipeline flanges. Conductive earthing rings of stainless steel create

conductive connection with the measured substance. Usually, potential equalization is carried out by

means of the reference earthing electrode in the measuring tube. In exceptional cases, the equalizing

currents may run through the reference electrode based on the device earthing conception. This may

lead to deterioration of the sensor, e.g. by electrochemical disintegration of the electrodes. In such

cases, it is necessary to use the earthing rings for potential equalization. This holds true for two-phase

or two-component flows in which the medium is blended badly or its components cannot be blended.

In general it can be said that using the earthing rings is always the protection against stray currents and

the warranty of correct measurement at the same time.

The flow sensor is provided with the earthing screw of stainless steel for the earthing cable supplied

with the mounting accessories. Then this cable must be conductively connected with the earthing rings.

The earthing rings are not part of our standard package and must be ordered separately. Chemical

durability of the material must correspond with the liquid to be measured; it is usually made of the

same material as the sensor electrodes. While mounting, it is necessary to insert seals in both sides of

the earthing ring and take care that no part extends to the internal profile of the sensor (whirling and

turbulence of the medium).

Electrodes

The electrode material must be selected according to chemical resistance to the liquid to be measured.

The purity of the electrodes may have an influence on measurement accuracy, their heavy foulness

may cause even the interruption of the measuring function (isolation from the liquid). It is not necessary

to clean the electrodes right after delivery before their installation in the pipeline. If the electrodes

indicate signs of foulness, clean them with a soft cloth or use a chemical cleaning agent. Mind

damaging to the lining! During routine operation, in case of a great majority of liquids, it is not

necessary to clean the flow meter for the entire operation period of the flow sensor; self-cleaning by

flow of the liquid is sufficient (recommended velocity is over 2 m/sec).

PTFE, PFA and ETFE lining

Meters with PTFE lining are equipped with protective covers to prevent the sealing surfaces from

damaging during transportation or storage and from changing the shape (due to elastic memory of

the PTFE material, it is restraightened to the tube). Protective covers may be removed only right

before the installation. If these covers are removed due to a check, it is necessary to replace them

immediately.

Carry out the installation at the lowest point of the pipeline to avoid the occurrence of vacuum. Never

detach and damage the rim of the PTFE lining turned up to the of flow sensor faces. Remove the covers

Loading...

Loading...