Technical and instalation

manual FLOW 38 Batch Page 9 (of 49) COMAC CAL s.r.o.

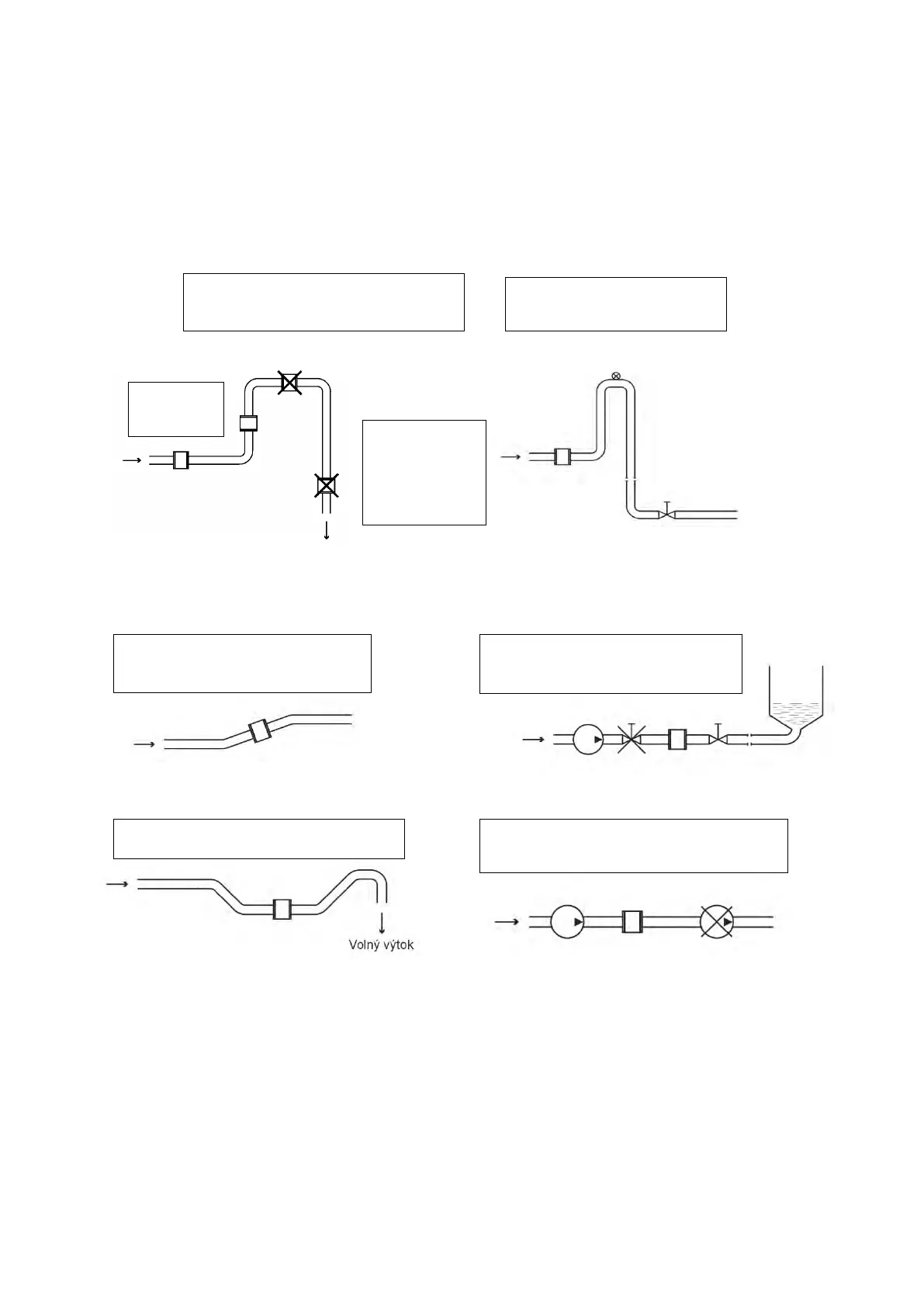

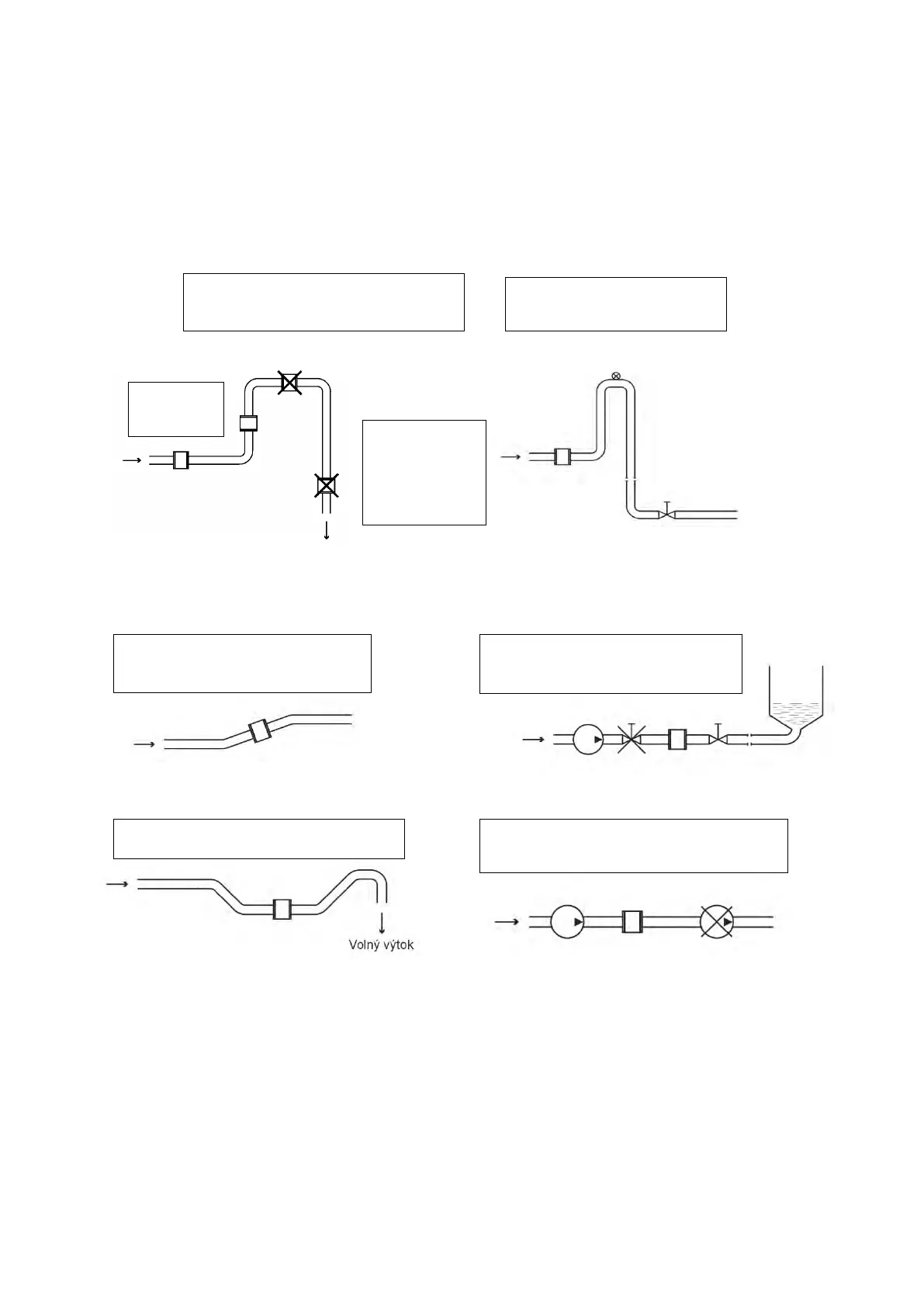

Installation examples

Trouble-free and exact operation of the meter is dependent on its correct location in the system. The

most frequent methods of the placement are shown in the following figures:

Recommended installation locations Downtake pipe

Horizontally laid pipeline Long pipeline

Free inlet or outlet Pumps

The flow of liquid flow in the flow sensor should be steady and free of whirling. For this reason,

straight sections of pipeline with the same ID as that of the flow meter before and after the flow sensor

(with permissible deviation of +5%). Recommended minimum length of straight sections is 5×d before

the flow sensor and 3×d after the flow sensor where d is the inside diameter of the meter in millimetres.

The same principles apply before and after the flow sensor in case of bi-directional flow measurement.

Recommendations

• In case of whirled up flow, extend the calming sections of pipeline or integrate a flow

conditioner.

Install an air bleed valve

after the sensor ⊗

Place the sensor in a slightly

ascending pipeline

empty;

erroneous

measurement

Install controls and shut-off

valves always after the sensor

Built in the U-shaped pipeline

The flow meter must not be installed

in the suction side of the pump

Bubbles are accumulated in the

pipeline; erroneous measurement

Loading...

Loading...