35

MACHINE PREPARATION

MACHINE PREPARATIONMACHINE PREPARATION

MACHINE PREPARATION

18.

18.18.

18.

SOLUTION TANK

SOLUTION TANK SOLUTION TANK

SOLUTION TANK

Take off the water inlet plug and check that, the solution filter, placed on the left bottom

side, has been assembled properly.

19.

19.19.

19.

SOLUTION WATER

SOLUTION WATERSOLUTION WATER

SOLUTION WATER

Fill the solution tank with clean water at a temperature not more than 50

°C and add

liquid detergent in the proper concentration following the instructions of the

manufacturer. Excess foam could damage the suction motor, so use only the minimum

amount of detergent necessary. Reassemble the cover.

WARNING!

WARNING!WARNING!

WARNING! Always use low foam detergent. To avoid the production of

foam, before starting to clean, put a minimum quantity of antifoam liquid

into the recovery tank. Never use pure acid

Never use pure acid Never use pure acid

Never use pure acid

20.

20.20.

20.

BRUSH ASSEMBLY

BRUSH ASSEMBLY BRUSH ASSEMBLY

BRUSH ASSEMBLY

1.

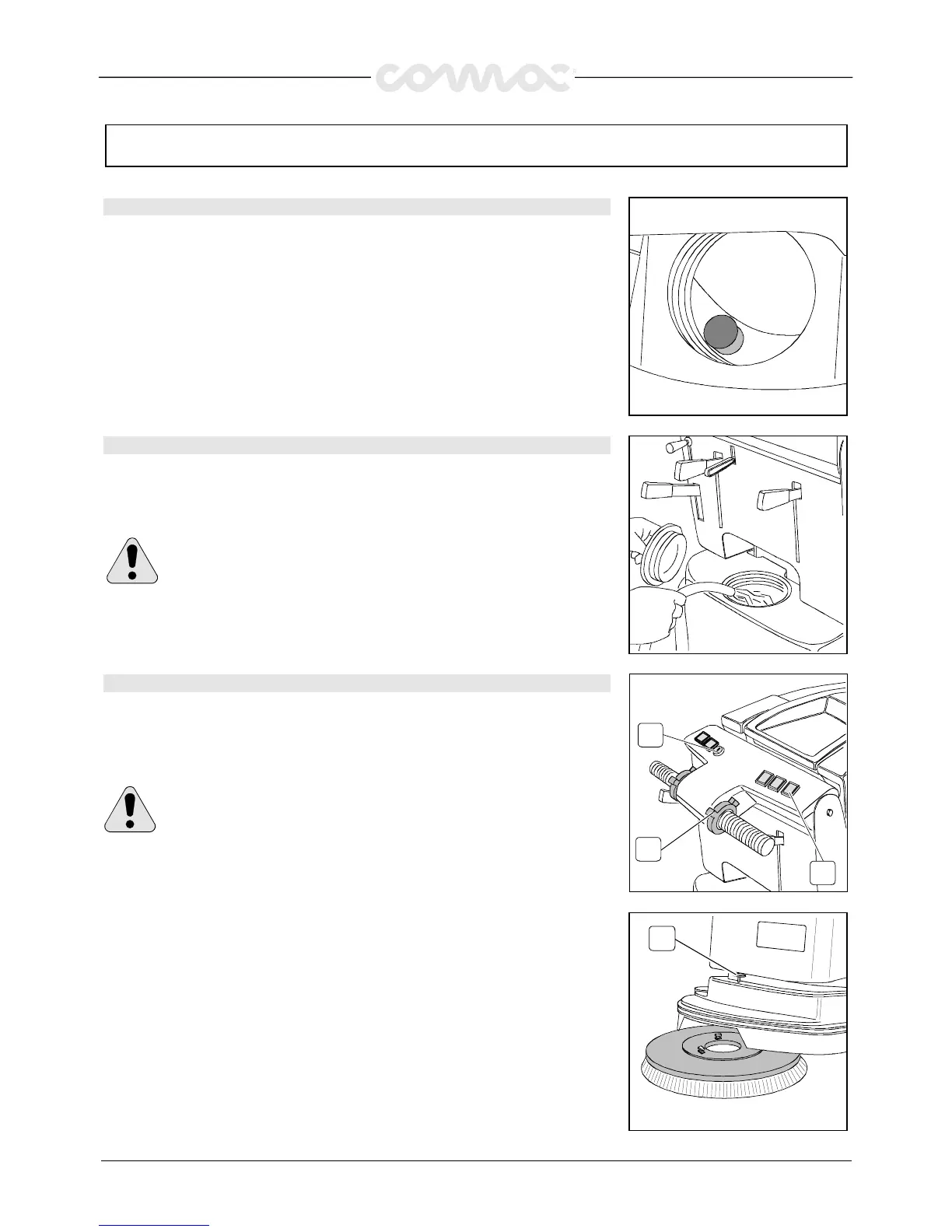

With the brush base in lifted position, insert the brush placing it in correspondence

with the plate under the brush base.

2.

Lower the brush base, turn the key (1) into position ON, press the brush switch (2),

push the lever (3) on the handle bar. At this point the brush is coupled.

WARNING!

WARNING!WARNING!

WARNING! During this operation make sure that, there are not any

objects or persons close to the brush.

1

3

2

3. Adjust, through the knob (1), the height of the splash guard rubber so that it touch

the floor.

The adjustment has to be repeated regularly depending on the brush wear.

1

Loading...

Loading...