Return the Control to Service

After the required work is completed, disconnect the

control from the test set and follow this procedure to return

the control to service:

1. While still in service shop, appropriate personnel must

verify that all control settings are correct.

2. Reconnect the ground cable to the control.

3. Control cable properly connected and supported.

4. Plug in the control battery.

Note: The Form 6 pole-mount recloser control will not

power up until AC power is applied.

5. Verify the selector switch on the Power Supply/Battery

Charger Board is set to the correct position based

upon the incoming power supply:

• For 120 VAC incoming power, the selector switch

must be set to the 115V position.

• For 240 VAC incoming power, the selector switch

must be set to the 230V position.

6. Apply AC power to the control.

7. Disable GND TRIP BLOCKED.

A. Press the CHANGE button on the Operator Panel to

enter the CHANGE mode.

B. Depress the GND TRIP BLOCKED button within ten

seconds after entering the CHANGE mode.

Note: Once selected (or after ten seconds), the control

returns to normal operation.

8. Verify the control clock is set to the current time after

AC power has been reapplied.

Note: The control clock may require resetting if the operating

power has been disconnected for more than thirty

days. Refer to Service Information S280-70-4

(ProView 4.X.X) or S280-70-21 (ProView 5.X.X) Form

6 Microprocessor-Based Recloser Control

Programming Guide for information on setting the

control clock.

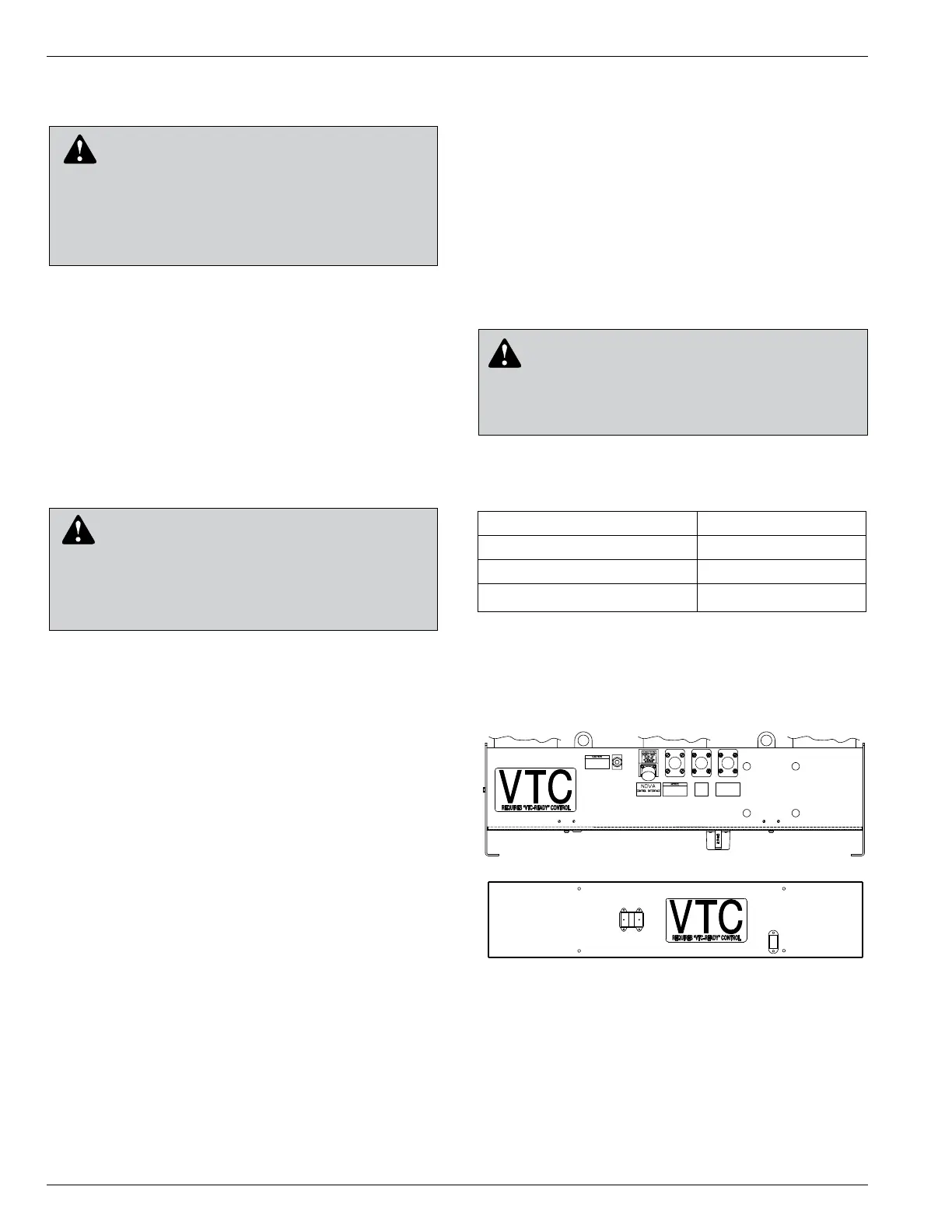

RECLOSER VTC INTERFACE

Control-Powered Type NOVA reclosers with serial numbers

100,000 and above, as listed in Table 15, require a VTC-

ready control. They are equipped with a 19-pin control

cable receptacle and can be identified by labels prominently

displayed on the bottom of the recloser tank and on the

side near the 19-pin receptacle, as shown in Figure 50

below.

For more information on the Control-Powered NOVA

Interface, refer to Service Information S280-42-1.

Form 6 Microprocessor-Based Pole-mount Recloser Control Installation and Operation Instructions

52

CAUTION: Equipment misoperation. Verify that

the 120/240 VAC selector switch is correctly set

for incoming voltage. Failure to comply may cause

misoperation (unintentional operation) of the control

and/or equipment damage resulting in personal injury.

T278.0

CAUTION: Equipment misoperation. Do not

connect this control to an energized recloser until

all control settings have been properly programmed and

verified. Refer to the programming information for this

control. Failure to comply can result in control and

recloser misoperation, equipment damage, and personal

injury. G110.3

CAUTION: Equipment misoperation. The control-

powered NOVA reclosers that require a VTC

interface must be used with VTC-ready controls. Failure

to use a VTC-ready control will result in failure to trip or

close. G144.0

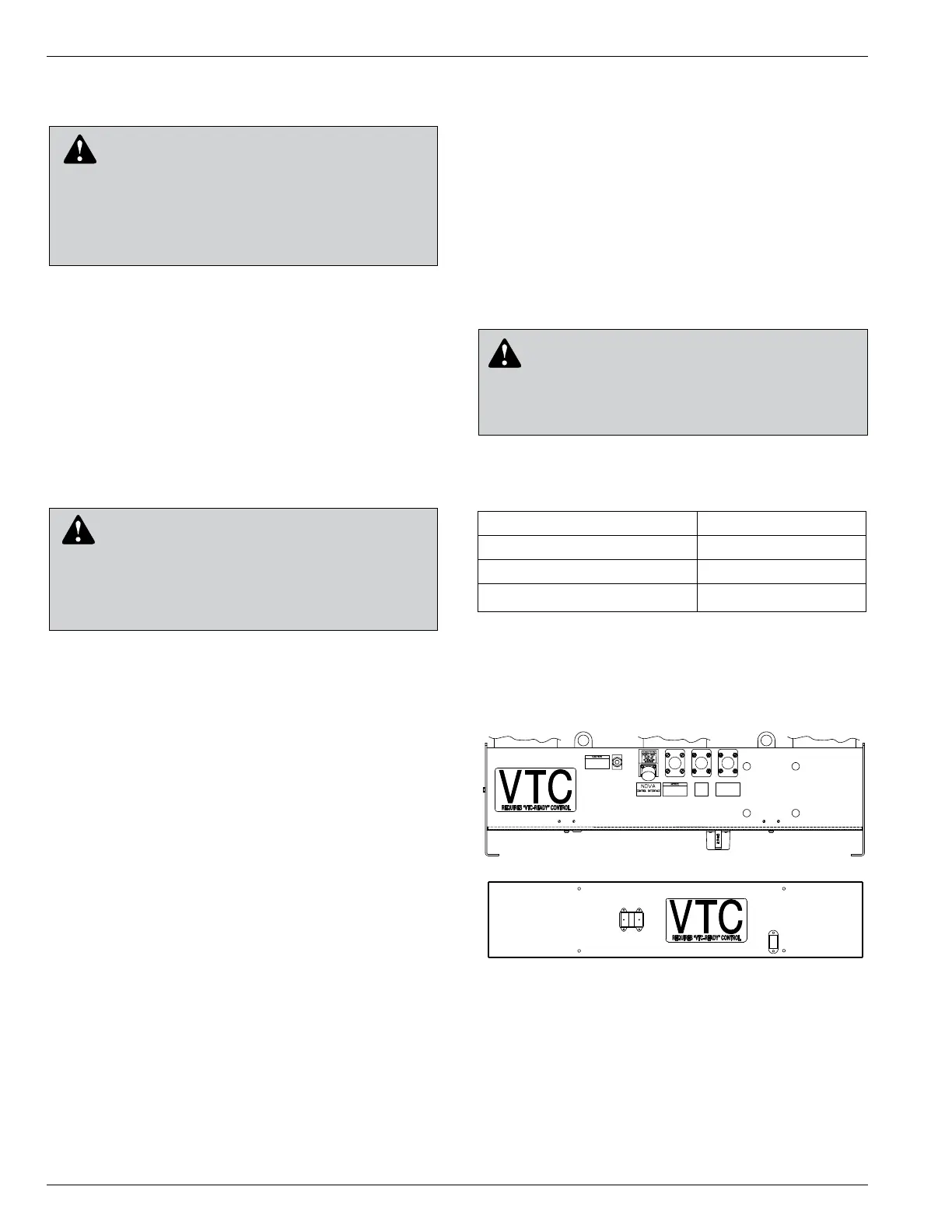

Figure 50.

Receptacle side view and bottom view of NOVA

recloser tank, showing placement of VTC label.

TABLE 15

Serial Number Break for Control-Powered NOVA Reclosers

with VTC

Control-Powered NOVA Serial No.

NOVA15 100,000

NOVA27 100,000

NOVA38 100,000

Note: Control-powered NOVA reclosers with serial numbers

below those listed in Table 15 do not require a VTC-

ready control. Refer to the recloser nameplate for the

serial number.

Loading...

Loading...