FEATURES

- 12 -

COROB™ D600 - D700 - D800TX

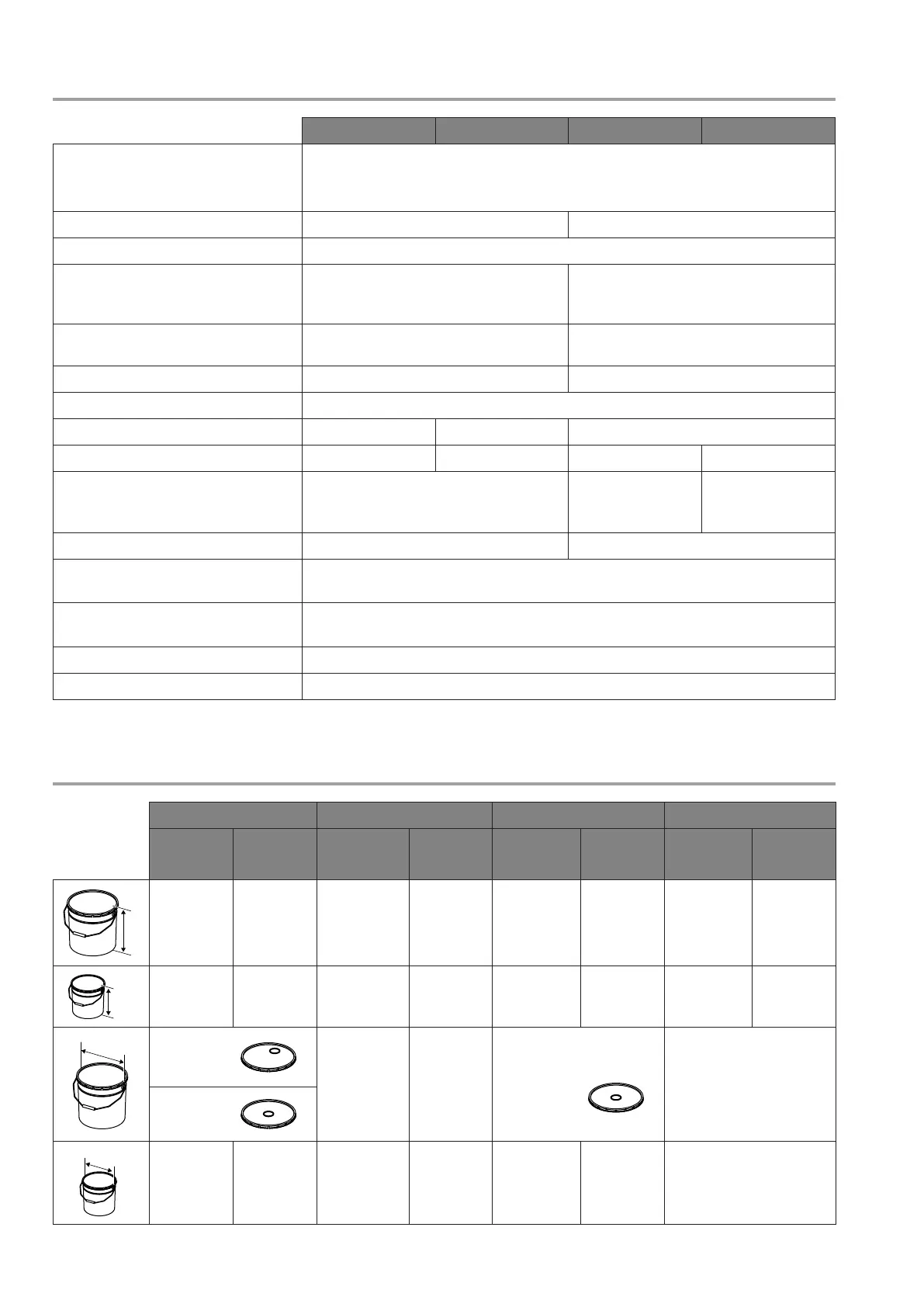

2.3 Standard and optional congurations

D600 TE D600 TI D700 D800TX

Canister capacity

3 Quarts - 4 Quarts - 6 Quarts - 4 Gallons (3 - 4 - 6 - 15 liters)

9.5 Quarts - 5.3 Gallons (9 - 20 liters)

(only on large additional canister modules)

Number of circuits maximum 24 maximum 32

Circuit with Standard pump standard

Nozzle center ow diameter*

1.10” (28 mm) (16)

1.54” (39 mm) (17-20)

1.77” (45 mm) (21-24)

1.10” (28 mm) (16)

1.54” (39 mm) (17-20)

1.77” (45 mm) (21-32)

Punching diameter

1.85” (47 mm) (20)

2.17” (55 mm) (21-24)

47 mm (20)

55 mm (21-32)

Additional canister modules maximum 2 maximum 4

Lift-up Autocap standard

Semiautomatic shelf standard optional standard

Automatic shelf optional standard \ optional

Manually-operated automatic

puncher

optional (with semiautomatic shelf) optional

optional (with

semiautomatic shelf)

Panel roll conveyors standard optional

Laser Bung Hole Locator

(B.H.L.)

optional

No-Dry-Nozzle Humidier

System

optional

Circuit with LAB pump optional

Circuit with HF pump** optional

* Hole diameter for pre-punched cans = ow diameter + 0.59” (15 mm). The diameter may also vary based on the partition of water/solvent

circuits of the machine. ** One HF circuit replaces two standard circuits.

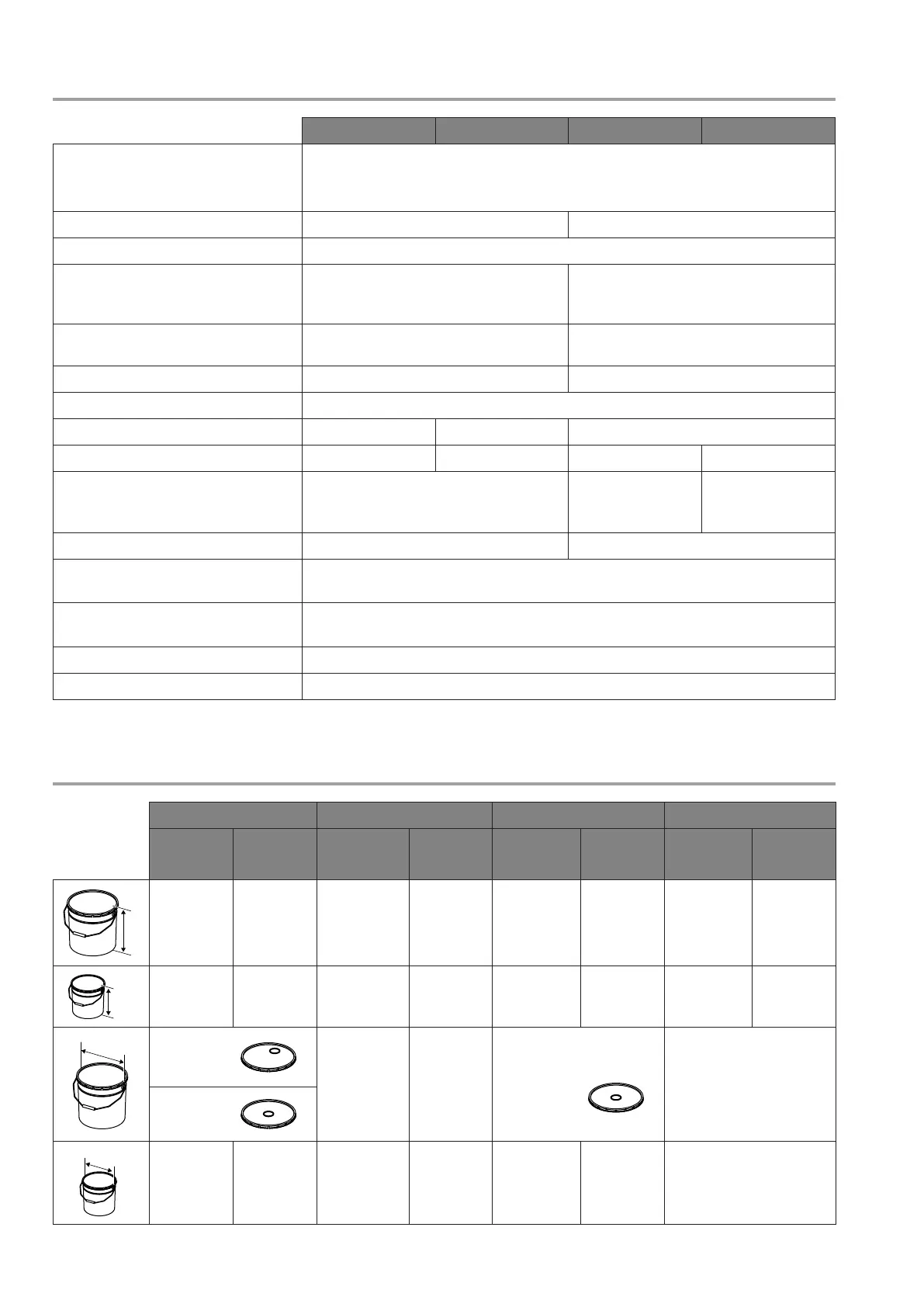

2.4 Usable cans

D600 TE D600 TI D700 D800TX

Standard

With

puncher

Standard

With

puncher

Standard

With

puncher

Standard

With

puncher

MAX

19.9”

(505 mm)

17.7”

(450 mm)

15.9”

(405 mm)

13.6”

(345 mm)

19.3”

(490 mm)

16.9”

(430 mm)

17.7”

(450 mm)

15.4”

(390 mm)

MIN

*

2.8”

(70 mm)

5.1”

(130 mm)

2.4”

(61.5 mm)

5.1”

(130 mm)

2.8”

(70 mm)

5.1”

(130 mm)

2.8”

(70 mm)

6.1”

(155 mm)

MAX

14.2”

(360 mm)

13.4”

(340 mm)

12.6”

(320 mm)

14.2”

(360 mm)

14.2”

(360 mm)

9.3”

(235 mm)

MIN

2.3”

(60 mm)

3.9”

(100 mm)

2.3”

(60 mm)

3.9”

(100 mm)

2.3”

(60 mm)

3.9”

(100 mm)

3.9”

(100 mm)

* Due to the high ll level of 1-Pint and 1-Quart cans (0.5 and 1-liter cans), COROB advises not to perforate them.

Loading...

Loading...