35

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

14 88

-electronics.com

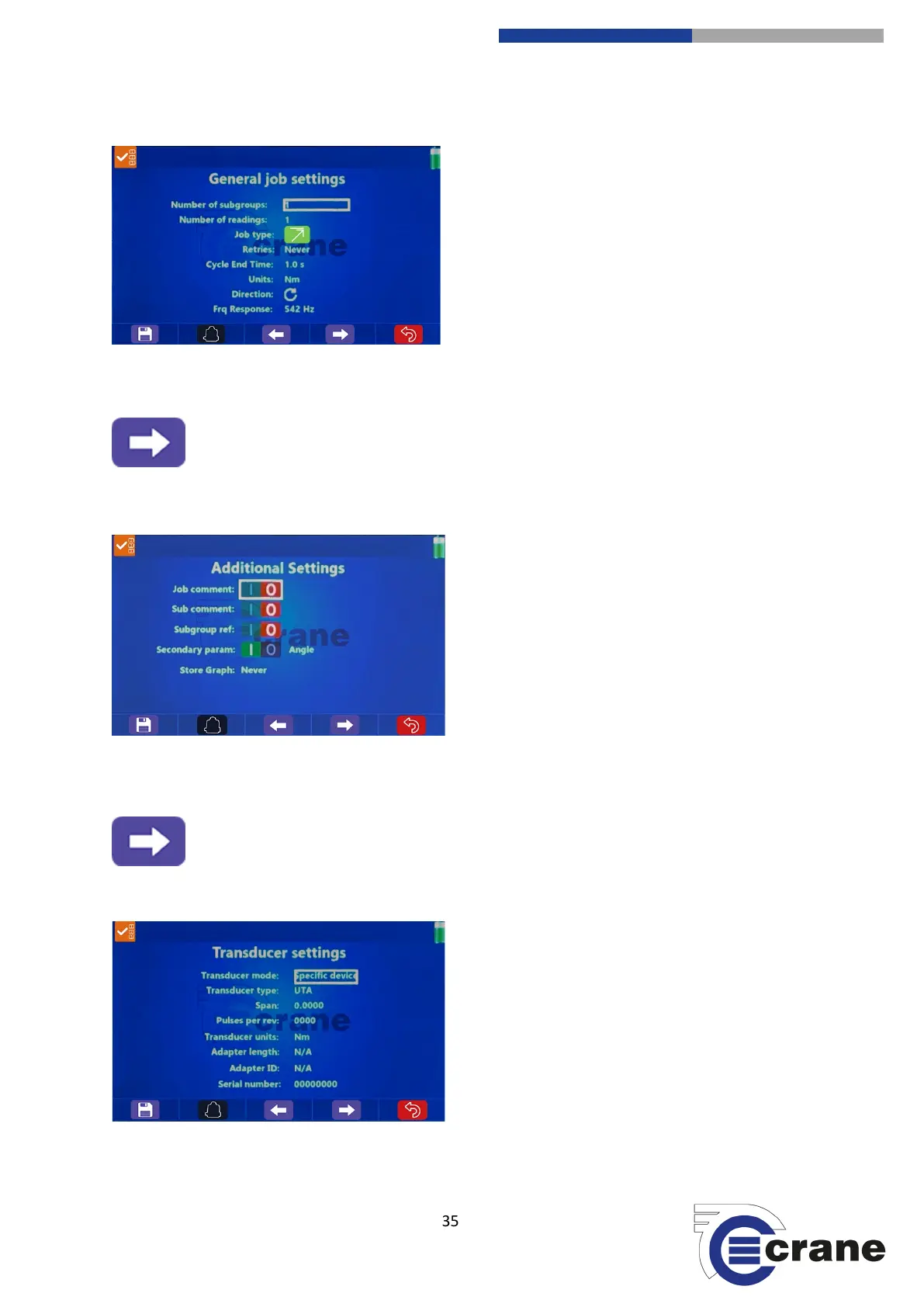

Screen 2: General Job Settings

Number of subgroups = (1 – number in global settings)

Number of readings = (1 – 50)

Job Type = (Peak, Impulse, Yield, MoveOn, Angle Control,

Audit, Force, Retighten, Click Dip)

Retries = (Never, Always, Manual, Single)

Cycle End Time = (0.2s, 0.5s, 1.0s, 2.0s, 5.0s, 10.0s, 20.0s)

Units = (Change if force or torque job type)

Direction = (CW, CCW, Auto)

Frequency Response

Screen 3: Additional Settings

Job Comment

Subgroup Comment

Subgroup Reference

(For each of the above it can state if it

occurs before or after)

Secondary Parameter = (Could be angle, pulse count or

peak torque depending on job type)

Store Graph = (Never, Always, Manual, NOK)

Audit Angle = (1 – 0 degrees) (Appears if Audit Job Type

selected)

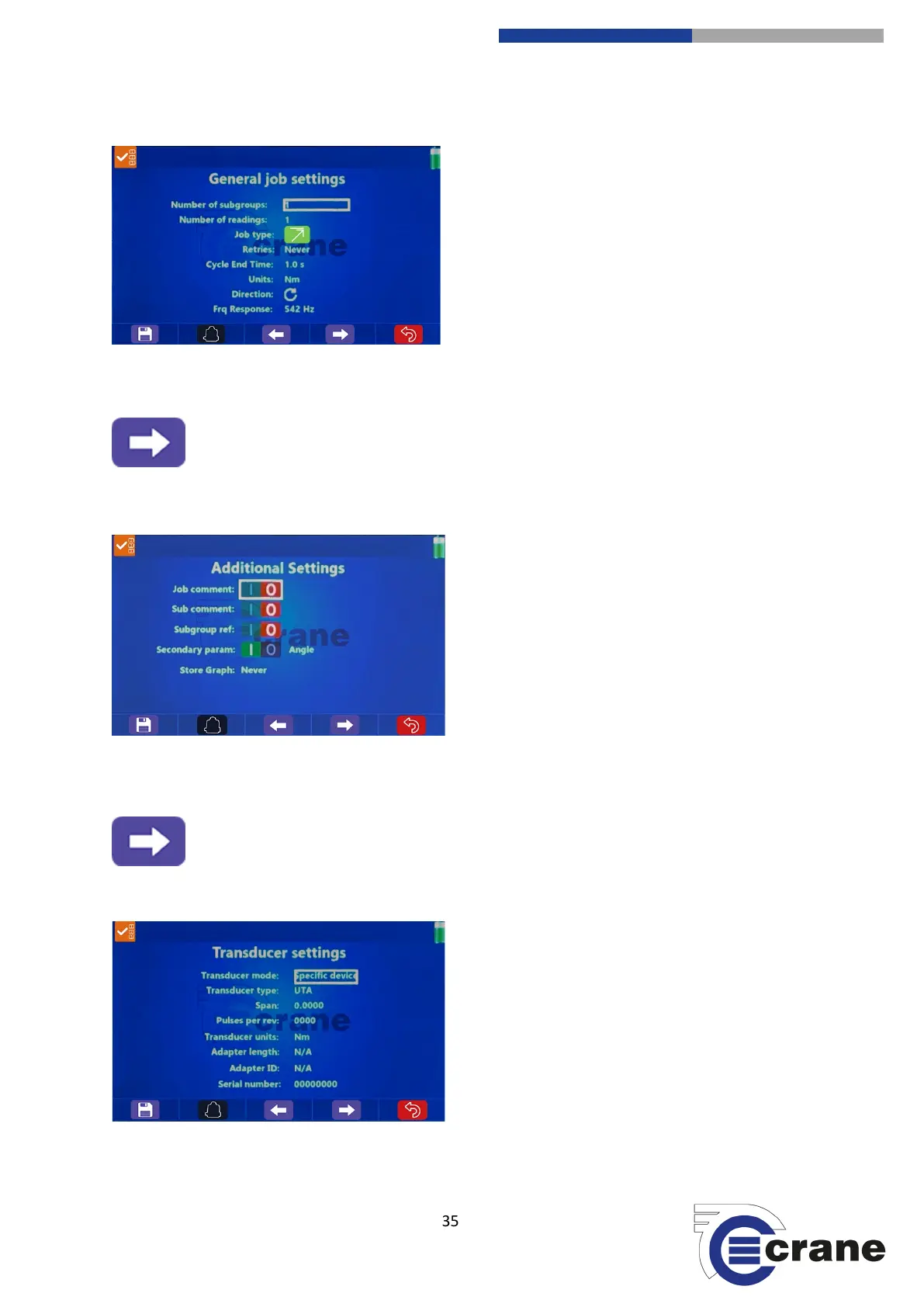

Screen 4: Transducer Settings

Transducer Mode = (Any appropriate, Fixed Type,

Specific Device)

Transducer Type = (UTA, IS, CheckStar Multi, Wrench)

Span = (1 – 8000)

Pulses per rev (PPR)

Transducer Units

Adapter Length

Loading...

Loading...