Cybex 425T Treadmill Service Manual

Service

Page 4-14

8. Remove the black brush assembly.

A. Using a large flat head screwdriver pry out the brush retainer on the drive motor that

secures the black wire. The brush and spring will pop out.

9. Examine the brush and commutator.

A. Inspect the commutator by looking through the top brush holder into the motor. Slowly spin

the motor by turning the flywheel. Look for noticeable damage and for signs of wear such

as arcing, pitting, burning, or uneven wear. Commutator bars that are ‘dirty penny’ brownish

copper are in great condition. Also, some commutator bars may be pitted or blackened

on one edge. Too many of these indicate a worn commutator, and the motor should be

replaced. The commutator may be cleaned with narrow commutator stone if carbon

build-up is present. Brush dust can be loosened from the motor surfaces where the brush

is placed by lightly filing the surfaces. Dirt and brush dust should be vacuumed out of the

motor.

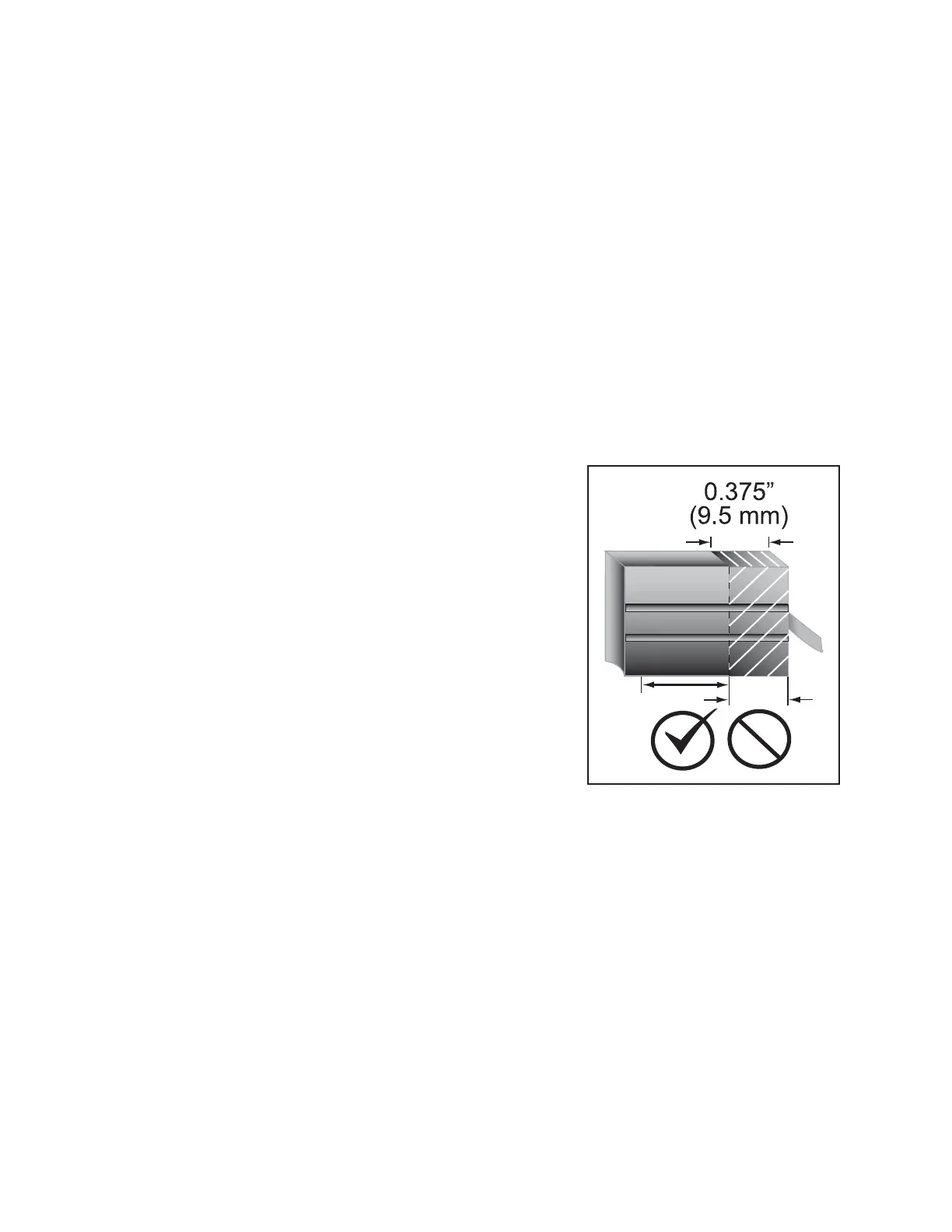

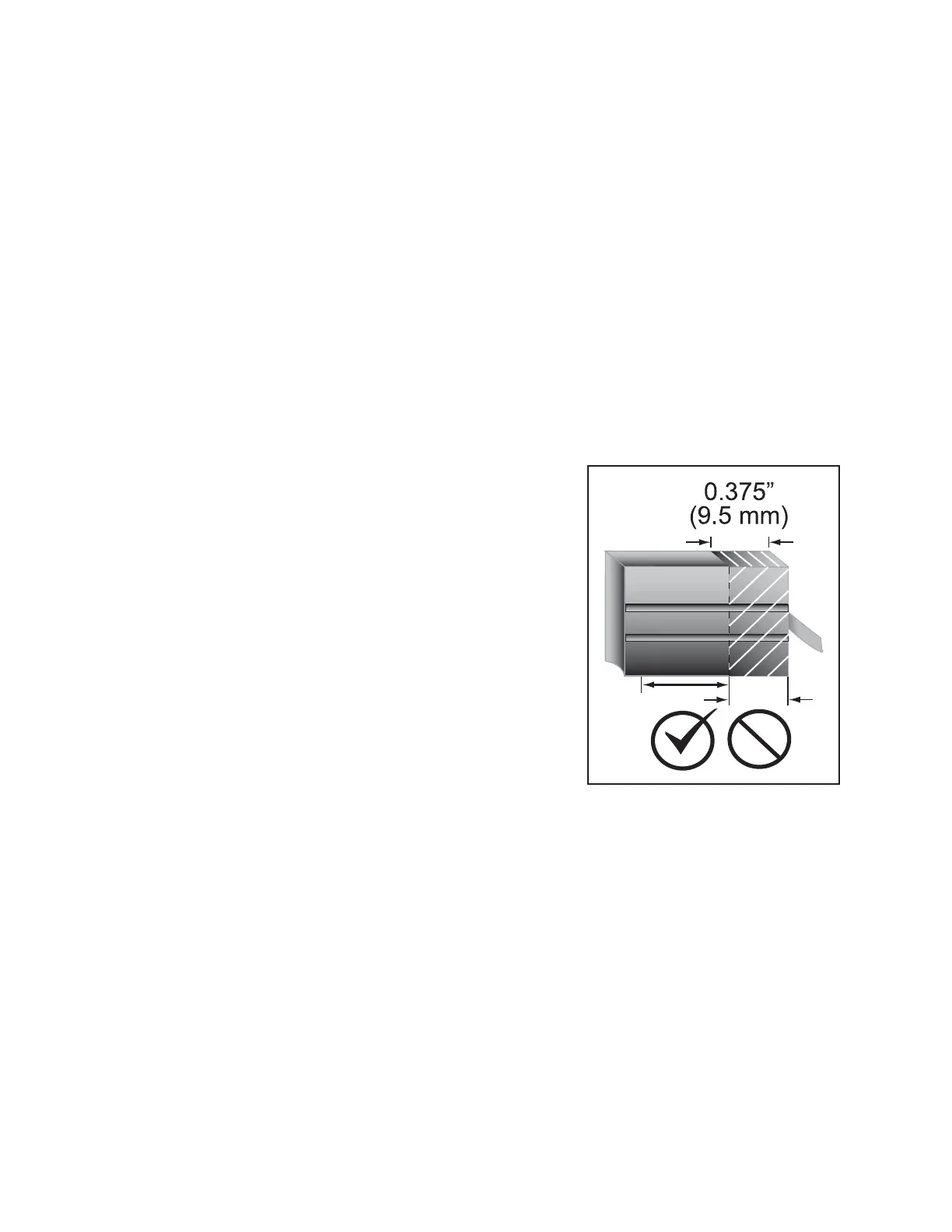

B. Inspect the brushes for signs of excessive wear or

cracks. The motor brushes must be replaced if one

or both is worn to .375” (9.5 mm) or less in length, is

broken or chipped, has a broken spring, or binds in

the motor. See Figure 13.

10. Replace the black brush assembly.

A. Slide the new brush into the motor brush holder. If

the new brush does not slide in and out easily, the

edges or corners of the brush can be lightly filed

down. If cleaning the motor, (see step 9A), and filing

the brush doesn’t allow the brush to slide easily in

the brush holder, the motor should be replaced.

NOTE: The motor may make a clicking noise as new

brushes wear in. If you reinstall the original brushes

it is good to install them facing their original position.

Reversing the orientation of the brush can cause a

clicking noise during operation until the brushes wear in.

B. Fully compress the spring by pushing as far into the brush holder as possible.

C. While compressing the spring, place the new brush retainer into the motor housing until

the brush retainer is fully seated into the motor housing.

D. Repeat steps 8A to 10C for the red brush assembly.

11. Connect the drive motor cables.

A. Place the new drive motor cables into the wire clamp retainer at the end of the motor.

B. Using the 7/16” open end wrench tighten the nut securing the drive motor cables in the

wire clamp retainer.

Figure 13

Loading...

Loading...