Page 30 of 60 IM 817-4

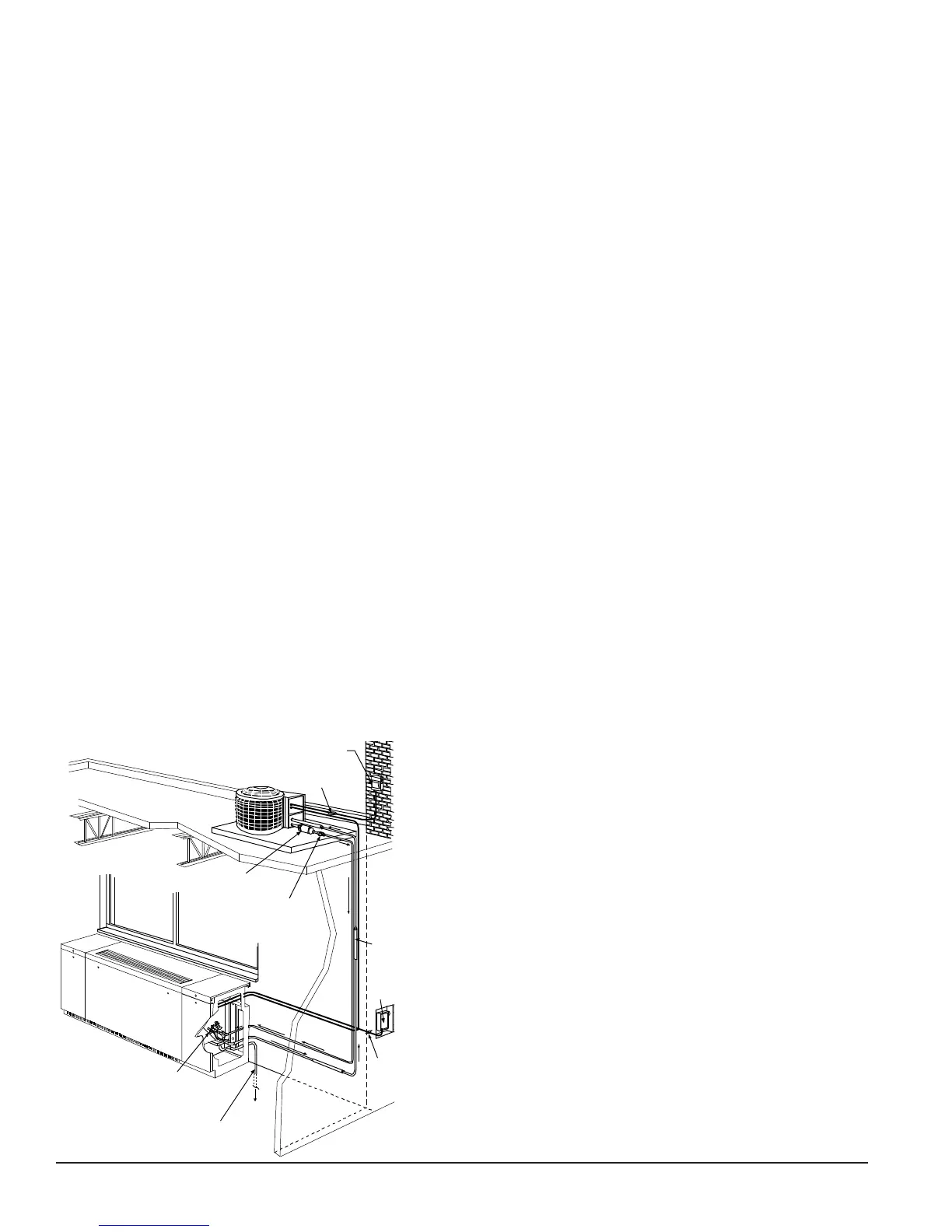

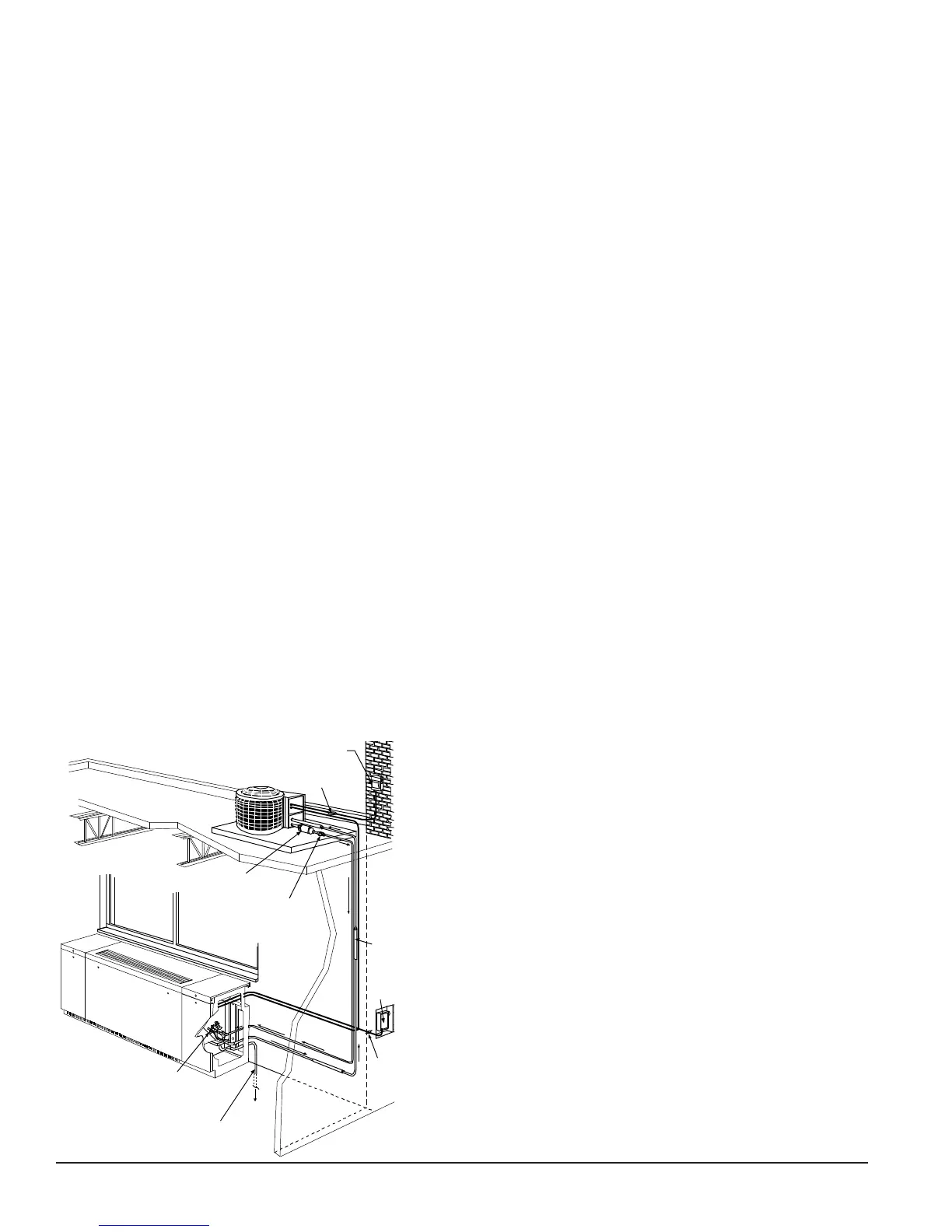

Figure 87 - Typical Piping and Wiring for Split System

2 Wires (+) Ground

To Open Sight Drain

TXV

(Thermal Expansion

Valve)

Filter Drier (Field Supplied)

Moisture Indicator Sight

Glass (Field Supplied)

Weatherproof Fused Disconnect Per NEC

2 Wires

(+) Ground

Insulated

Suction Line

Fused

Disconnect

Unit Ventilator Split Systems Guidelines

The following provides basic guidelines that will provide proper system

cooling and operation of an R-22 commercial DX/hot water system

for school applications. DX system components must be matched and

sized correctly (not oversized) for the load.

The DX system must incorporate the following, provided by others,

for proper operation:

•

Size piping per ASHRAE Refrigeration Handbook (correct

refrigerantandcompressoroilow),seegure88andtable21.

•

Use clean sealed refrigerant grade piping (prevent system

contamination)

•

Install Liquid Line Filter Dryer (clean/dry system to prevent

damageofoperatingcomponents),seegure89.

•

Install Liquid Line Sight Glass (indicates refrigerant dryness and

if liquid in liquid line - do not use the sight glass to determine

when refrigerant system is charged correctly

),seegure88.

•

Install pressure taps on the unit ventilator's liquid line and suction

lines for subcooling and superheat measurements at the unit

ventilator,seegures88and89.

•

Install High Pressure Switch at condensing unit wired in condenser

control system (protects compressor and refrigerant system from

excessive pressures - condenser fan failure or overcharging), see

gure90.

•

Install Low Pressure Switch at condensing unit wired in the

condenser control system (low refrigerant pressure switch

protects the system under low refrigerant suction conditions), see

gure90.

•

Install Low Ambient Temperature Switch at condensing unit wired

in the condenser control system (locks out mechanical cooling

below 60ºF - proper system operation and free economizer usage),

seegure90.

•

Incorporate Compressor Time Delay (5 minute) in condensing

unit control system (reduces excessive compressor cycling), see

gure90.

•

Single phase compressors - consider hard start kits to overcome

non-equalized pressure in refrigerant lines.

•

Incorporate Low Refrigerant Temperature Sensor (T4) in

condensing unit control system (T4 protects the system under low

refrigerantsuctionconditions)seegure90.

•

UV fans must continue to run upon Low Refrigerant Temperature

trip of T4 (controls by others) or S4 (MicroTech II) (evaporator

airowdissipatesresiduallowcoilsurfacetemperatures-suction

pressuresraised,coilfrostingreduced),seegure90.

•

UV fans must continue to run for set time period during unoccupied

mode after satisfaction of the space sensor (dissipates residual low

evaporator coil surface temperatures - reducing coil frosting), see

gure90.

•

Lock the Face and Bypass Damper (actuator spring return to full

face when de-energized) in the full face position during mechanical

cooling (full air through evaporator coil reduces low refrigerant

suction conditions, potential coil frosting)

•

When Brazing bleed Nitrogen through piping (reduced oxides and

blockage in piping/TXV)

•

Use Heat Sink when brazing to prevent overheating the TXV

valve body and bulb (avoid valve damage and erratic operation),

seegure86.

•

Verify the TXV bulb securely attached at 2 or 10 o’clock for

7/8" and smaller diameter suction line piping (proper suction gas

sensingandreducedhunting)Seegure86.

•

Insulate the TXV bulb (reacts to refrigerant temperatures and not

ambient),seegure88.

•

Insulatethesuctionlinepiping(minimumheatpickup),seegure88.

•

Evacuateandproperlychargetherefrigerantsystem,seegure89.

•

Charge to subcooling at the condensing unit per the condensing

unit manufacturer’s instructions, typically 15ºF to 16ºF at the

unit ventilator, subcooling at 95ºF outdoor ambient (results in

correct refrigerant distribution at the coil to prevent low suction

temperatures)

•

Adjust TXV for correct superheat to eliminate/minimize hunting,

seegure91.

•

Set superheat to 5ºF to 7

o

F at the UV coil suction line when

95ºF outdoor ambient (proper system superheat for optimum

performance). Allow system to settle for 20 to 30 minutes to reach

stable steady state conditions and then recheck/adjust superheat

if necessary, see table 23.

•

Compensate both subcooling and superheat for actual outdoor

ambient and indoor air temperatures

•

Inwindyareas,addwindbafestocondensingunitorbuilda

parapet (eliminate wind effect on condensing unit coil for proper

TXVrefrigerantowatlowerambient)

•

For lower ambient conditions install variable speed condenser fan

head pressure control to maintain head pressures between 180psig

and280psig(forproperTXVrefrigerantowatlowerambient),

seegure90.

Loading...

Loading...