Page 32 of 60 IM 817-4

Do not force adjustment stem of TXV. When adjusting superheat

setting, there are a maximum of 10 turns on the stem. Turning

adjustment stem after reaching stop will damage valve.

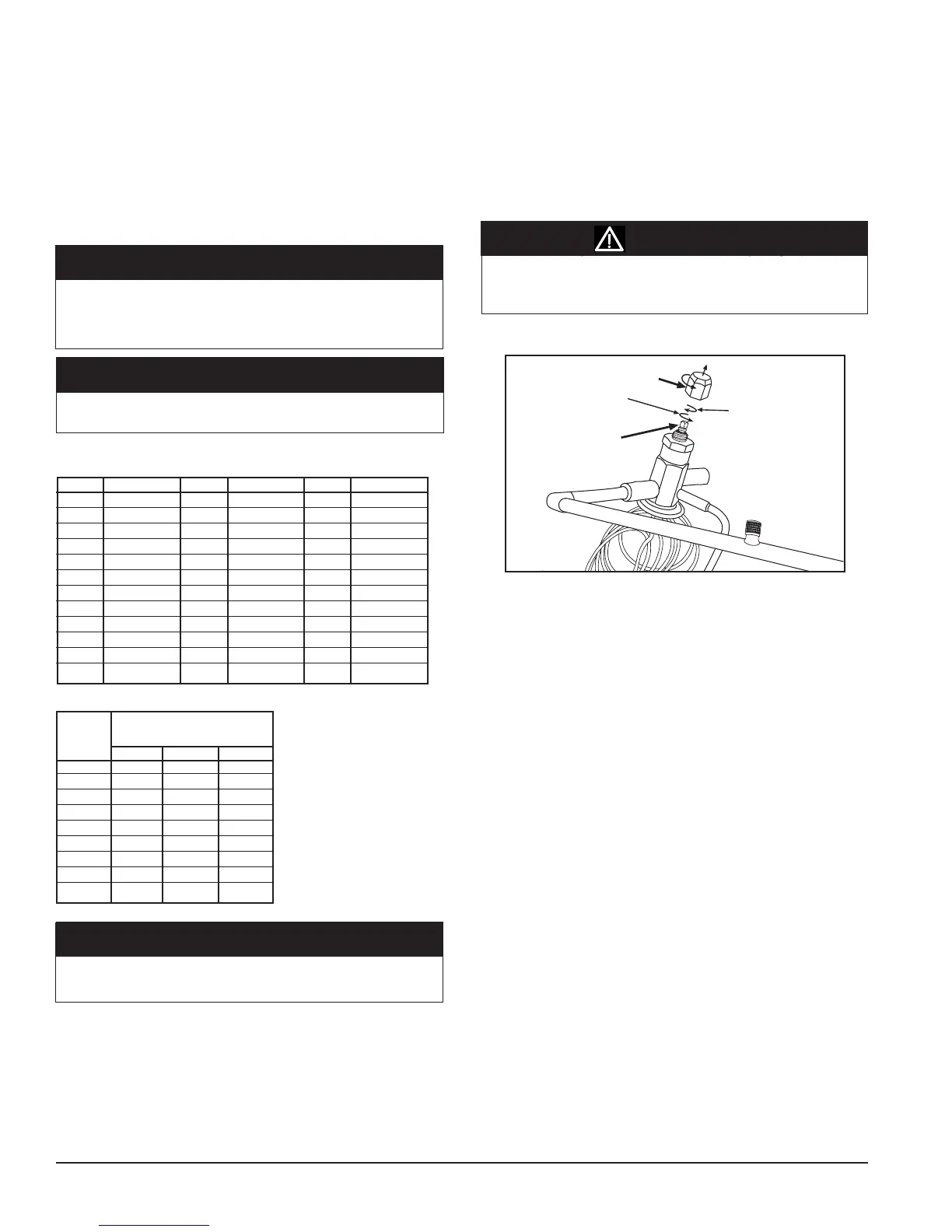

Table 22 —Saturated Temperature - Pressure Chart

(ºF) R410A-PSIG (ºF) R410A-PSIG (ºF) R410A-PSIG

32 101.1 44 127.7 80 235.8

33 103.2 45 130.2 85 254.7

34 105.2 46 132.6 90 274.5

35 107.4 47 135.1 95 295.5

36 109.5 48 137.5 100 317.6

37 111.7 49 140.1 105 340.9

38 113.9 50 142.6 110 365.4

39 116.2 55 147.0 115 391.2

40 118.4 60 170.1 120 418.3

41 120.7 65 185.2 125 446.9

42 123.0 70 201.1 130 476.8

43 125.4 75 218.0 140 541.4

Determining System Superheat

After the subcooling has been determined, check system superheat.

1. Determine required superheat from superheat range, table 23.

2. Measure suction line temperature 6 inches from service valve.

3. Measure suction line pressure at service valve and determine

saturated suction temperature from table 22.

4. Subtract saturated suction temperature from measured temperature

to obtain superheat.

5. Refer to table 23 and adjust charge as required for correct superheat

at ambient conditions.

Each time that charge is added or removed from the system,

allow the system to run approximately 20 - 30 minutes before

pressure and temperature readings are taken and superheat

calculations made.

If system hunting occurs or subcooling is reduced, it may be

necessary to adjust TXV to obtain correct superheat.

Superheat Adjustment

1.

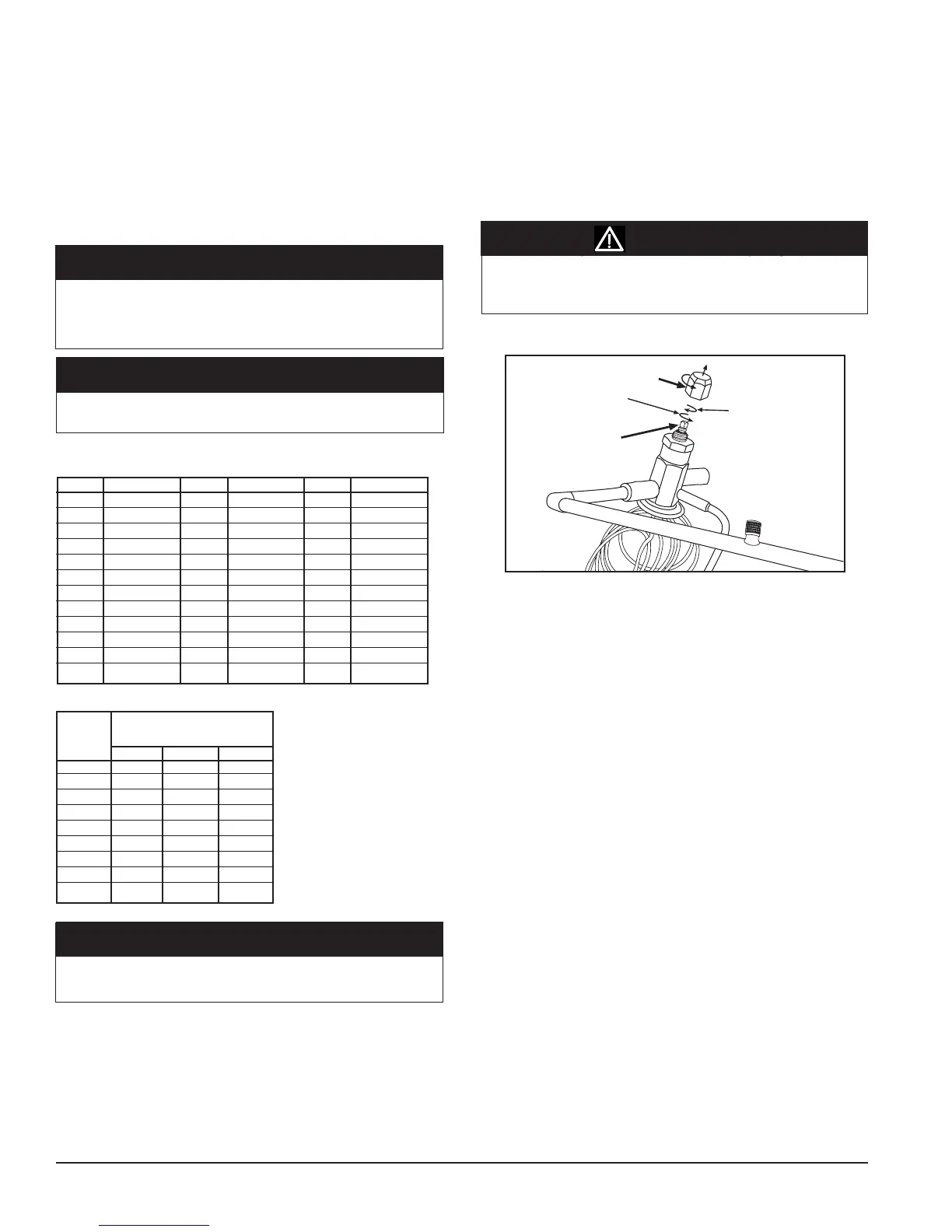

Removethesealcapfromthermalexpansionvalve(seegure91).

2. Turn the adjustment screw clockwise to increase superheat and

counterclockwise to decrease superheat (see gure 91). One

complete 360º turn changes the superheat approximately 3-4ºF,

regardless of the refrigerant type. As much as 30 minutes may be

required for the system to stabilize after the adjustment is made.

3. Replace and hand-tighten seal cap.

Figure 91 - Superheat Adjustment of TXV

Superheat

Adjustment Screw

Counterclockwise To

Decrease Superheat

Clockwise To Increase

Superheat

Remove Seal Cap

Outdoor

Indoor Coil Air Inlet Temp.

Ambient

DB/WB (50% RH)

75/63 80/67 85/71

105 * * 8-10

100 * 3-5 9-11

95 * 5-7 11-13

90 * 9-11 13-15

85 5-7 10-12 15-17

80 8-10 12-14 18-20

75 10-12 15-17 21-23

70 13-15 19-21 24-26

65 15-17 21-23 26-28

Table 23 —Superheat Range

Typical conditions - 95ºF ambient, 75 psig suction, 285 psig

head pressure, 6 - 7º superheat, 15ºF subcooling

NOTICE

NOTICE

CAUTION

NOTICE

Loading...

Loading...