R25/35DV1 Si01-501

204 Removal Procedure

3.7 Removal of Compressor

Procedure Warning Be sure to wait 10 minutes or more after turning off all power supplies

before disassembling work.

Step

Procedure Points

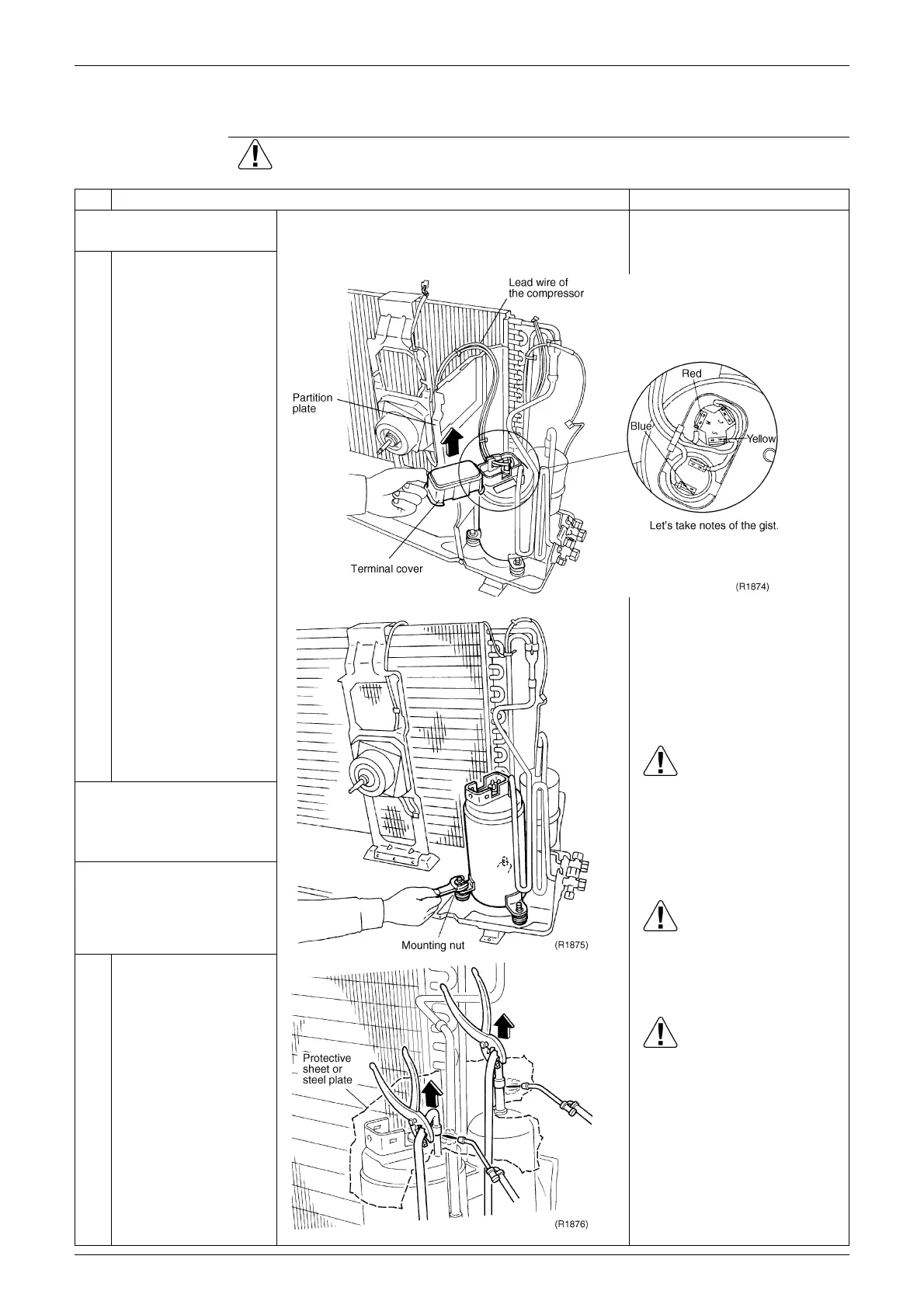

1. Removing the parts

around the compressor.

Be careful so as not to burn

the compressor terminals or

the name plate.

1

Remove the terminal

cover, the lead wires of

the compressor and the

partition plate so as not

to be burnt out by a gas

brazing machine.

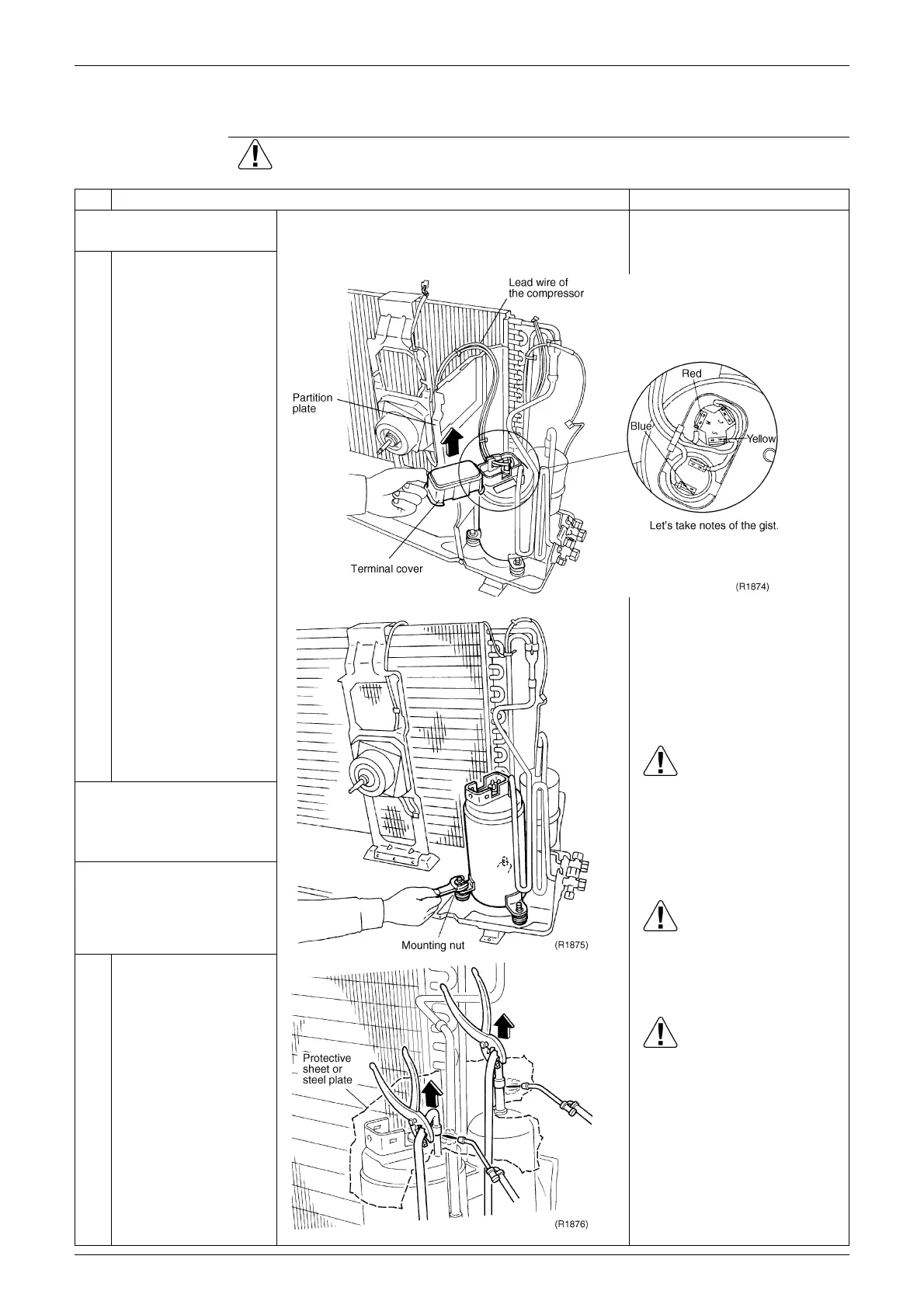

2

The compressor’s

mounting nut to be

removed is one piece.

Warning

Since it may happen that

refrigeration oil in the

compressor will catch fire,

prepare wet cloth so as to

extinguish

fire quickly.

Warning

Ventilate when refrigerant

leaks during the work.(If

refrigerant contacts fire, it will

cause to arise toxic gas).

Caution

Be careful about pipes and so

on, which were heated up by a

gas brazing machine, so as

not to get burnt on your

hands.

Pay attention so that the

heat exchanger’s fins will not

be burnt.

3

Remove the nut by

means of an open-end

wrench.

Begin your work after

recognizing complete

empty of refrigerant in the

refrigerant circuit.

Be sure to apply

nitrogen’s permutation

when heating up the

brazing part.

1

Remove the brazing

part on the compressor

discharge side.

2

Heat up the brazing

part on the compressor

suction part and then

remove it.

3

Lift the compressor and

remove it.

Loading...

Loading...