Troubleshooting - Outdoor Unit Related Si18-201

290 Service Diagnosis

3.3.27 Overvoltage, Low Voltage

Outdoor Unit

Indication

U2

Method of

Malfunction

Detection

Power supply system error is detected using the voltage of inverter DC unit.

Malfunction

Decision

Conditions

When, after starting the compressor, the voltage reached to below 210V over 450V before it

exceeded 320V, or to below 260V or over 450V after it exceeded 320V once.

"

When a power supply system error is generated 4 times, the system shuts down.

(The 4-time counter resets itself when no outdoor unit abnormality occurs within 60-minute

cumulative time after the error generation.)

Supposed

Causes

"

Electrolytic capacitor malfunction

"

PAM module malfunction

"

Faulty power transistor

"

Disconnection·Faulty connection of internal wiring

"

Faulty reactor

"

Faulty PC board

"

Instantaneous power failure

"

Mismatching with power supply of feedback control system

Troubleshooting

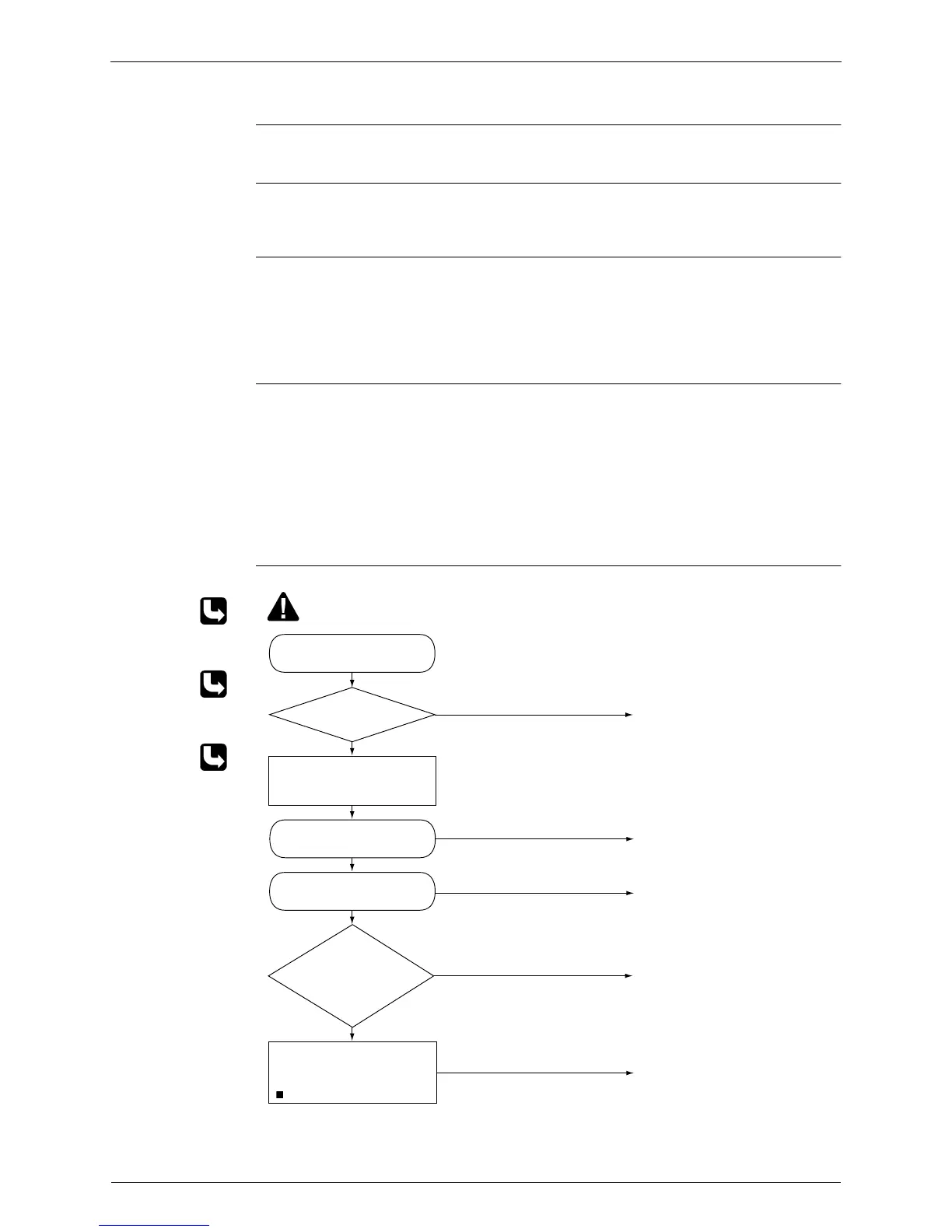

Check No.5

Refer to P.302

Check No.12

Refer to P.307

Check No.13

Refer to P.308

YES

Could be causes on site.

Replace if any abnormality.

Replace control PC board,

filter PC board if the voltage

is not within the range.

Replace active module.

As the system will not shut

down, use as it is.

Is the input

voltage within a range of

220-240V±10%?

(MF046)

NO

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Check No. 12

Electrolytic capacitor

capacity check

OK

Check No. 13

Voltage check when starting

the compressor

Check No. 5

Main circuit wiring

connection check

Measure the voltage at both

ends of electrolytic capacitor

while the compressor is

operating.

YES

Does the

voltage reach to

approximately 370V within

approximately 2 seconds

after starting the

compressor?

NO

Do a long-term observation

on power supply voltage.

Supposed causes

n

Instantaneous power failure

Loading...

Loading...