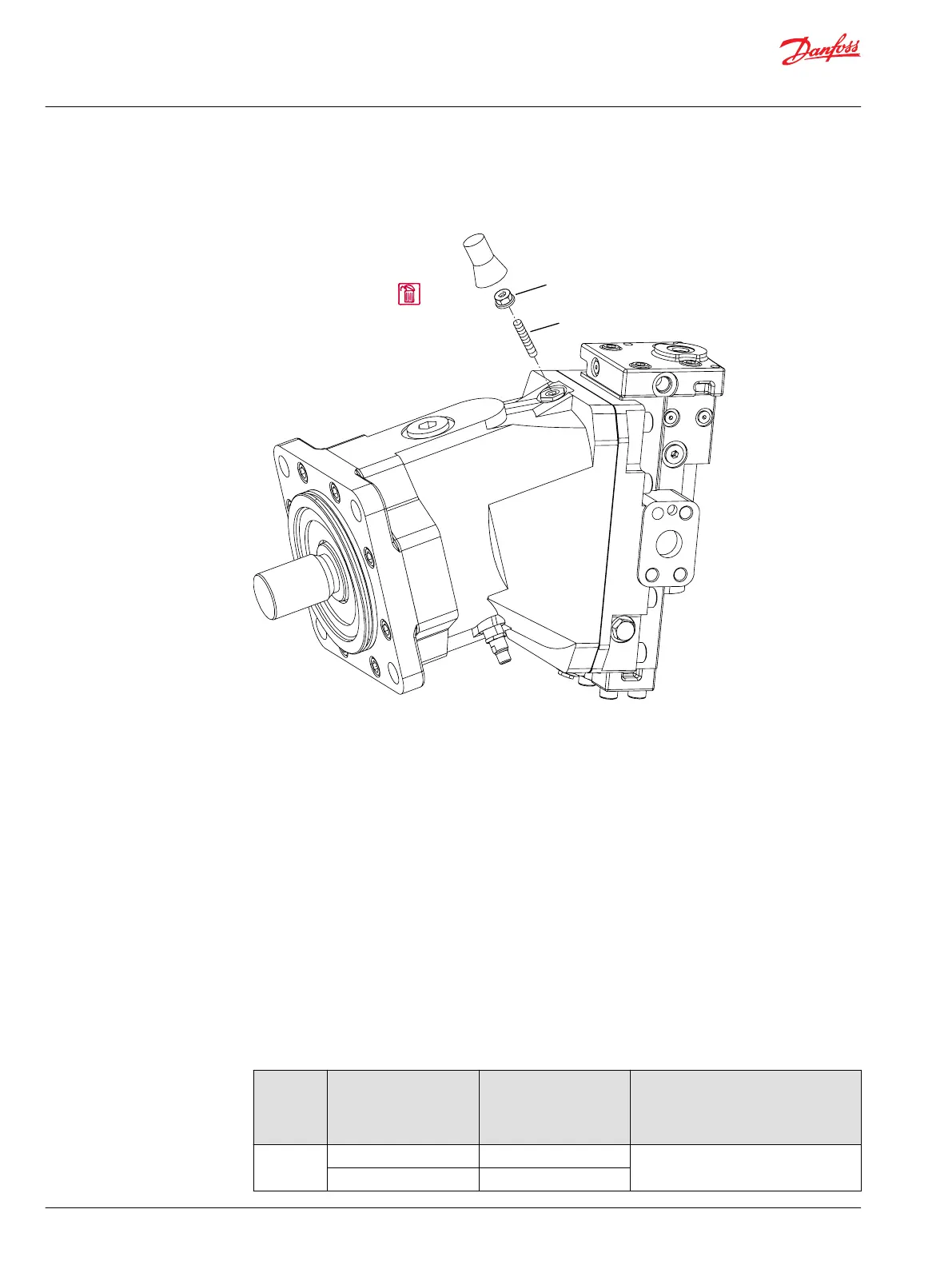

2. Discard the cap (Q120) after comparing it with a new one to make sure the new one fits.

Minimum displacement limiter

Q120

Tamper

resistant

cap

Y20

Y10

P101216E

3. Hold adjusting screw (Y10) using a 5 mm or 6 mm internal hex wrench.

4. Loosen the sealing lock nut (Y20), using a :

•

17 mm hex wrench for 060cm³ and 080cm³ frame size motors

or

•

19 mm hex wrench for 110cm³, 160cm³, and 250cm³ frame size motors.

5. Turn the adjustment screw (Y10) for the desired displacement (following the table) with a:

•

5 mm hex wrench for 060cm³ and 080cm³ frame size motors

or

•

6 mm hex wrench for 110cm³, 160cm³, and 250cm³ frame size motors.

Rotating the adjustment screw clockwise increases the minimum displacement of the motor; rotating

the adjustment screw counterclockwise decreases it.

The minimum displacement setting changes (see chart) for each full revolution of the adjustment

screw. Major changes in minimum displacement setting may require a different size adjustment

screw.

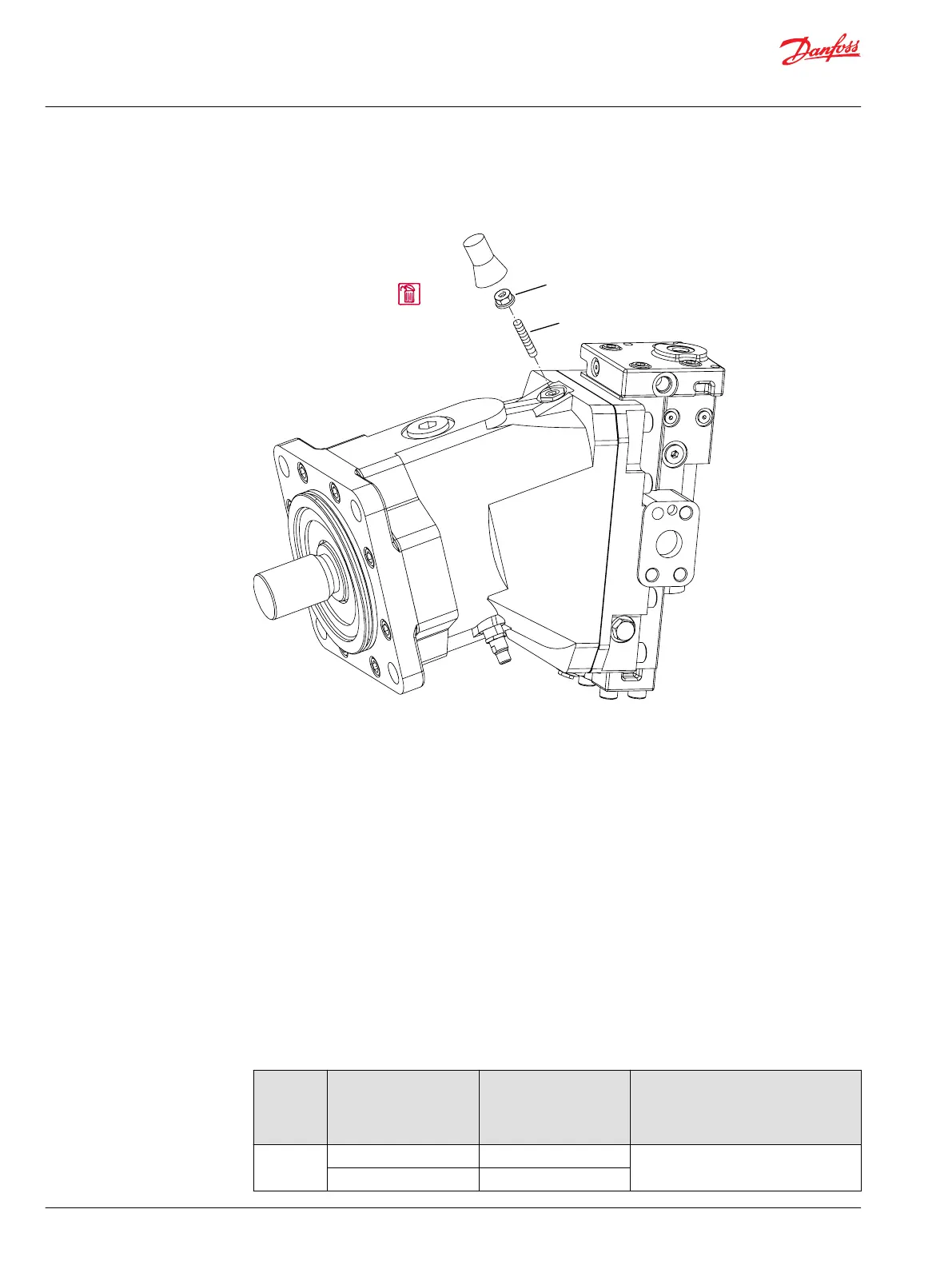

Adjustment screw and displacement

Frame size Minimum displacement

range cm³ [in³]

Screw size and length

mm [in]

Approximate change in minimum

displacement per revolution of

adjusting screw

cm³/rev [in³/rev]

60 12 - 29 [.73 - 1.77] M10 x 65 [2.56] 1.5 [.09]

30 - 36 [1.83 - 2.20] M10 x 80 [3.15]

Service Manual

Series 51 and 51-1 Motors

Adjustments

34 |

©

Danfoss | March 2016 11008567 | AX00000013en-US0202

Loading...

Loading...