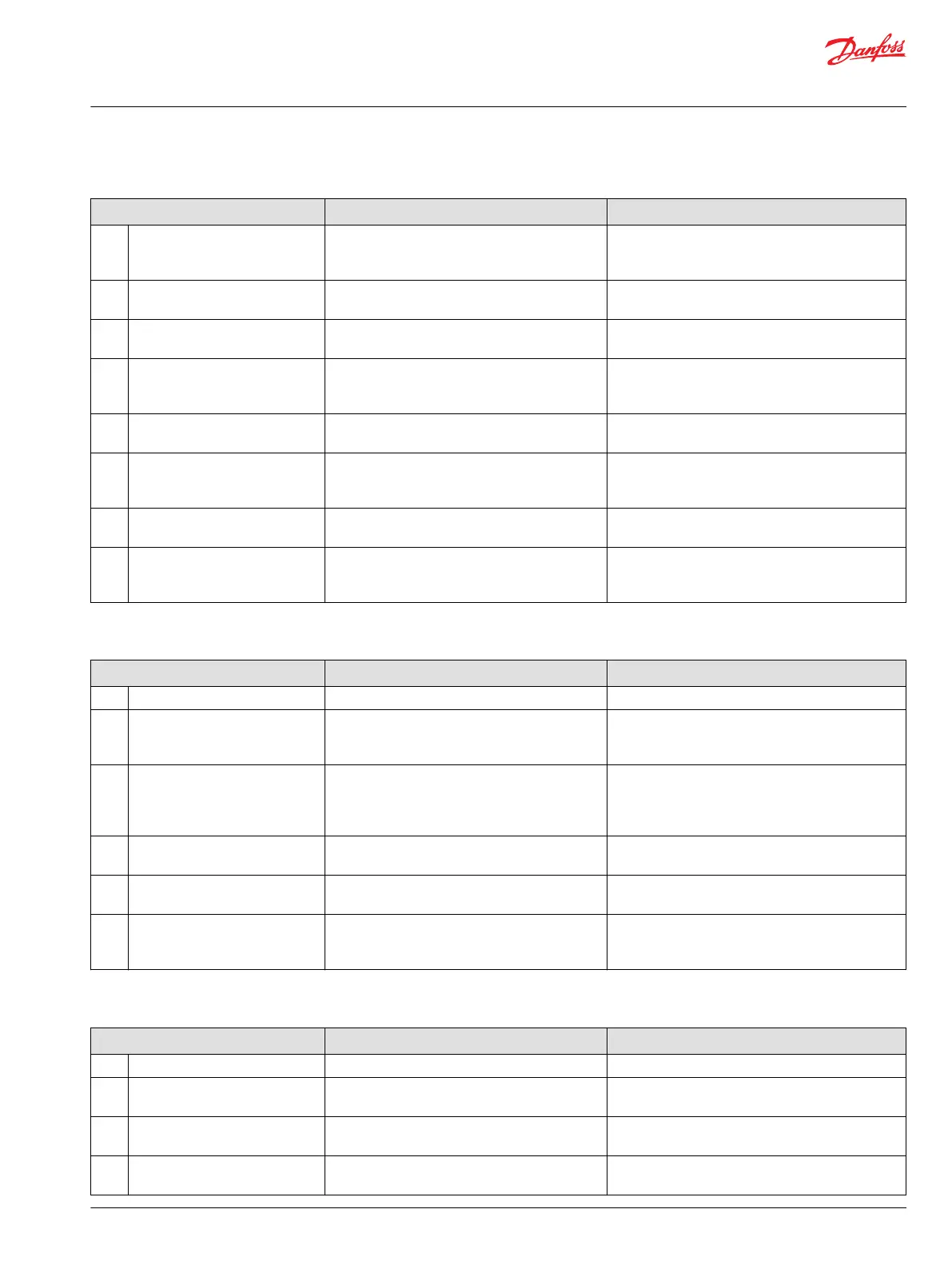

Sluggish system

Check Cause Corrective action

1.

Control orifices Blocked or restricted orifice will cause sluggish

response. Orifices installed to the wrong locations

will cause PCOR control to be sluggish.

Remove, inspect and clean all orifices. Ensure the

appropriate orifices are installed.

2.

Threshold setting (proportional

controls)

Inappropriately high threshold setting will shift the

motor at the wrong time.

Check threshold setting. Adjust if necessary.

3.

Control spool or piston A sticky 4-way spool or control piston will cause

sluggish response.

Clean and inspect the 4-way valve spool and control

piston. Replace if necessary.

4.

Pressure compensator setting Inappropriately low pressure compensating setting

will shift motor to maximum displacement at lower

pressure

Check pressure compensator setting. Adjust if

necessary.

5.

Control input signal An improper or erratic input signal to the control

may cause sluggish response.

Check input signal or electric current and correct if

necessary.

6.

Charge pressure Inappropriately low pressure setting at loop

flushing relief valve may cause improper supply

pressure to motor control.

Measure change pressure in forward and reverse.

Adjust loop flushing relief valve if necessary.

7.

System pressure Inappropriately low system pressure setting may

cause sluggish response.

Measure system pressure. Adjust pump pressure

limiter or system relief valve if necessary.

8.

Internal leakage Excessive leakage will cause lower charge pressure

and affect performance.

Install loop flushing defeat option and monitor case

flow. If case flow is excessive, motor may require major

repair. Contact your Danfoss service provider.

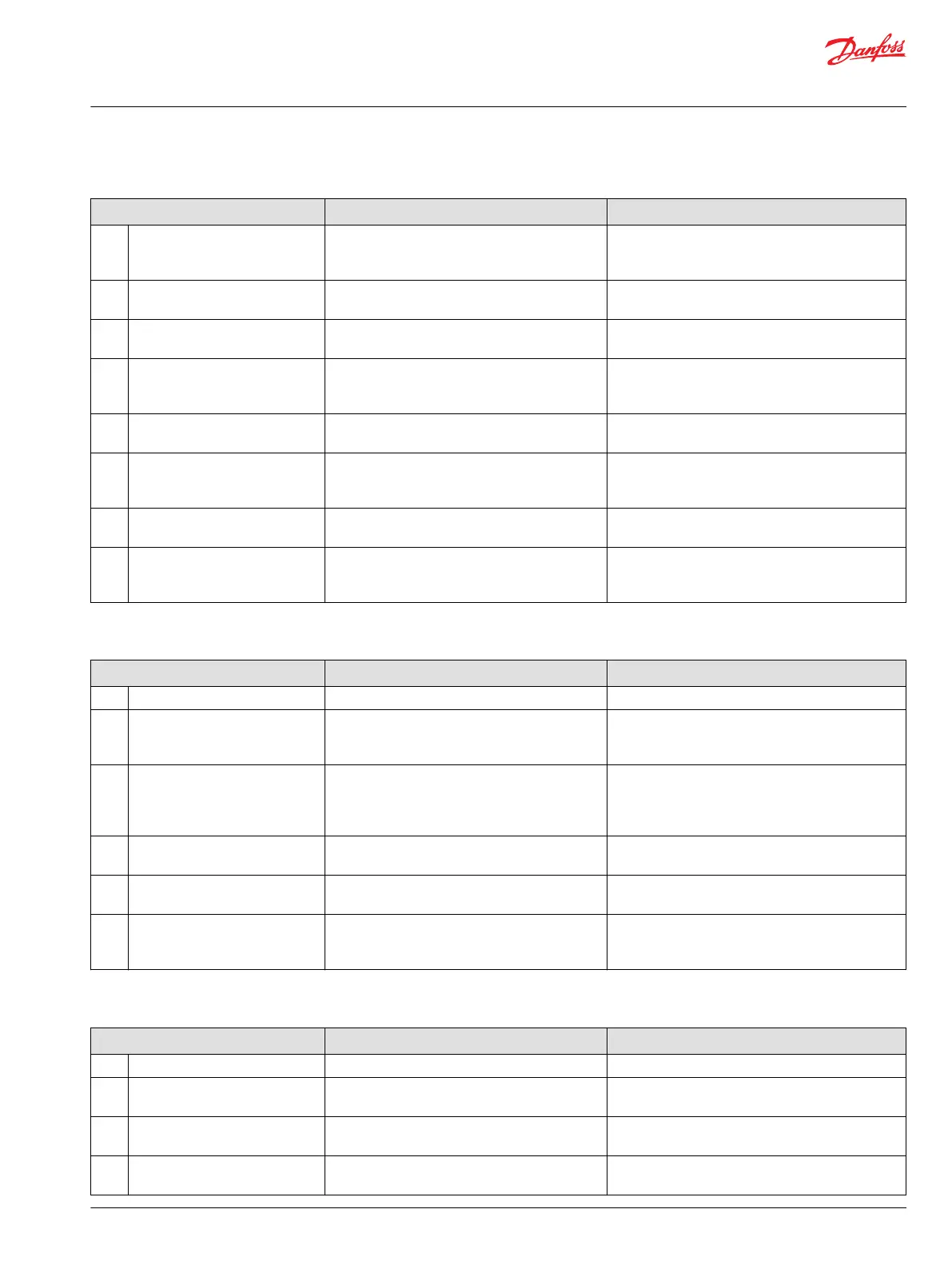

System operating hot

Check Cause Corrective action

1.

Oil level Insufficient hydraulic fluid will cause overheating. Fill reservoir to proper level.

2.

Heat exchanger Blocked heat exchanger or low air flow will not

sufficiently cool the system.

Check temperature upstream and downstream of heat

exchanger. Clean, repair, or replace heat exchanger if

necessary.

3.

Loop flushing charge pressure Inappropriately high loop flushing relief valve

setting will reduce or prevent loop flushing flow.

Improper orifice size will not give proper flow for

cooling purposes.

Monitor case drain flow. If low, adjust loop flushing

relief valve setting or replace with orificed type relief.

4.

System pressure If system relief valve settings are too low, excess

heat will be generated.

Adjust system relief valve settings.

5.

Air in system Entrained air generates heat under pressure and

causes cavitation

Look for foam or bubbles in reservoir. Check for leaks

on inlet side of charge pump.

6.

Internal leakage Excessive internal leakage will overheat the system. Install loop flushing defeat option and monitor case

flow. If case flow is excessive, motor may require major

repair. Contact your Danfoss service provider.

Excessive noise or vibration

Check Cause Corrective action

1.

Oil level in reservoir Insufficient hydraulic fluid will cause cavitation. Fill reservoir to proper level.

2.

Air in system Air bubbles may lead to cavitation. Look for foam or bubbles in reservoir. Check for leaks

on inlet side of charge pump.

3.

Shaft coupling Loose shaft coupling creates excess noise. Replace loose shaft coupling. Replace or repair motor

if shaft splines are worn excessively.

4.

Shaft alignment Misaligned shafts create excessive noise and

damage motor.

Correct shaft misalignment.

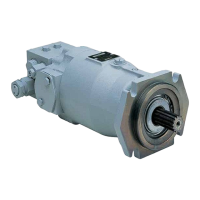

Service Manual

Series 51 and 51-1 Motors

Troubleshooting

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 29

Loading...

Loading...