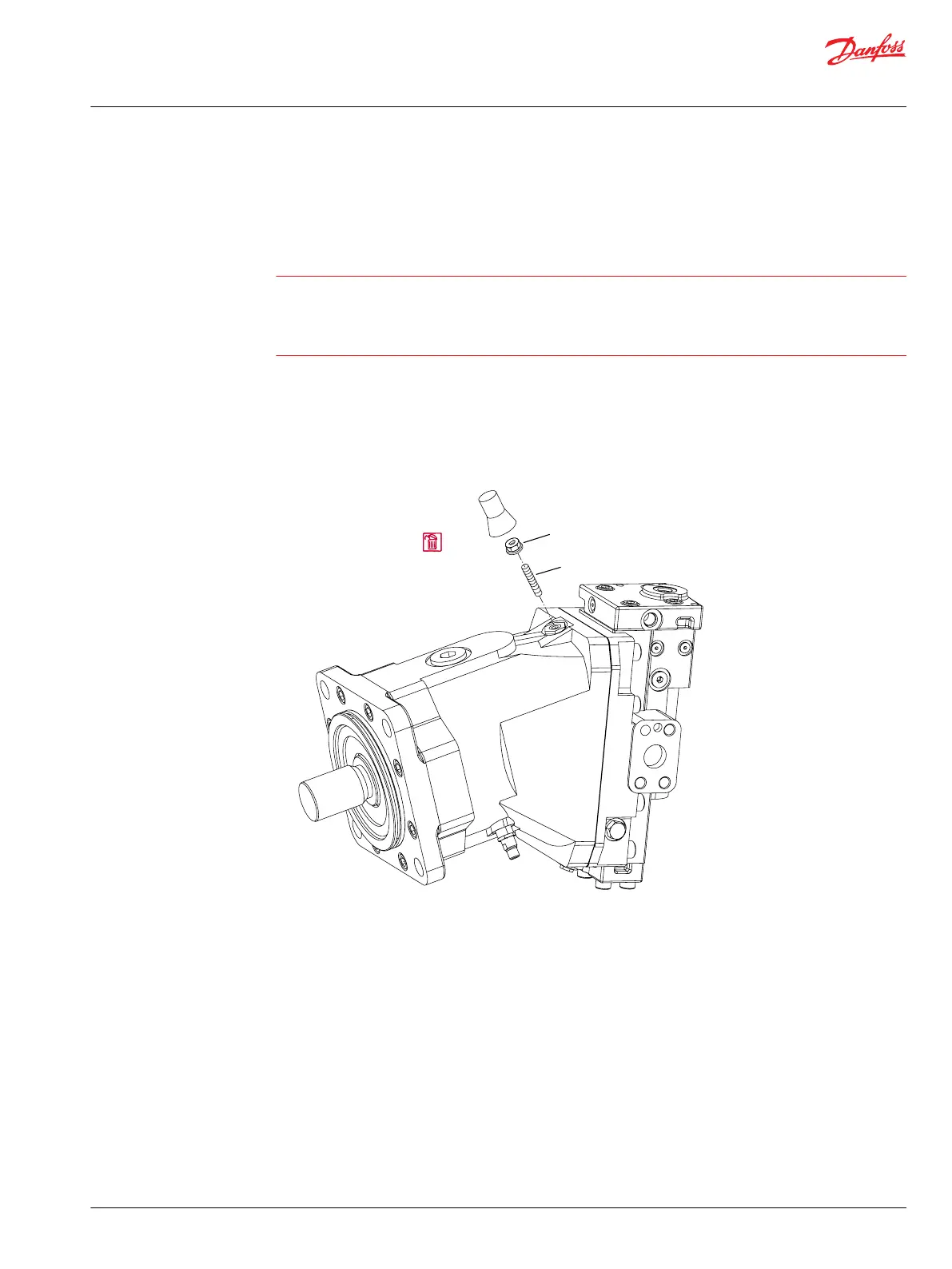

Minimum angle adjustment screw

Disassembly

Warning

Improper adjustment of the minimum displacement limiter can result in undesirable or unsafe speed

conditions. Consult with the original equipment manufacturer or your Sauer-Danfoss representative

before changing the minimum displacement setting. After adjustment, verify the minimum displacement

setting by testing: using an appropriate test apparatus.

1. Thoroughly clean all external surfaces before disassembly.

2. Remove the tamper resistant cap (Q120) covering the adjustment screw.

3. Discard the cap. Removing the cap destroys the locking device.

4. Measure the length of the screw (Y10) to assure correct reinstallation.

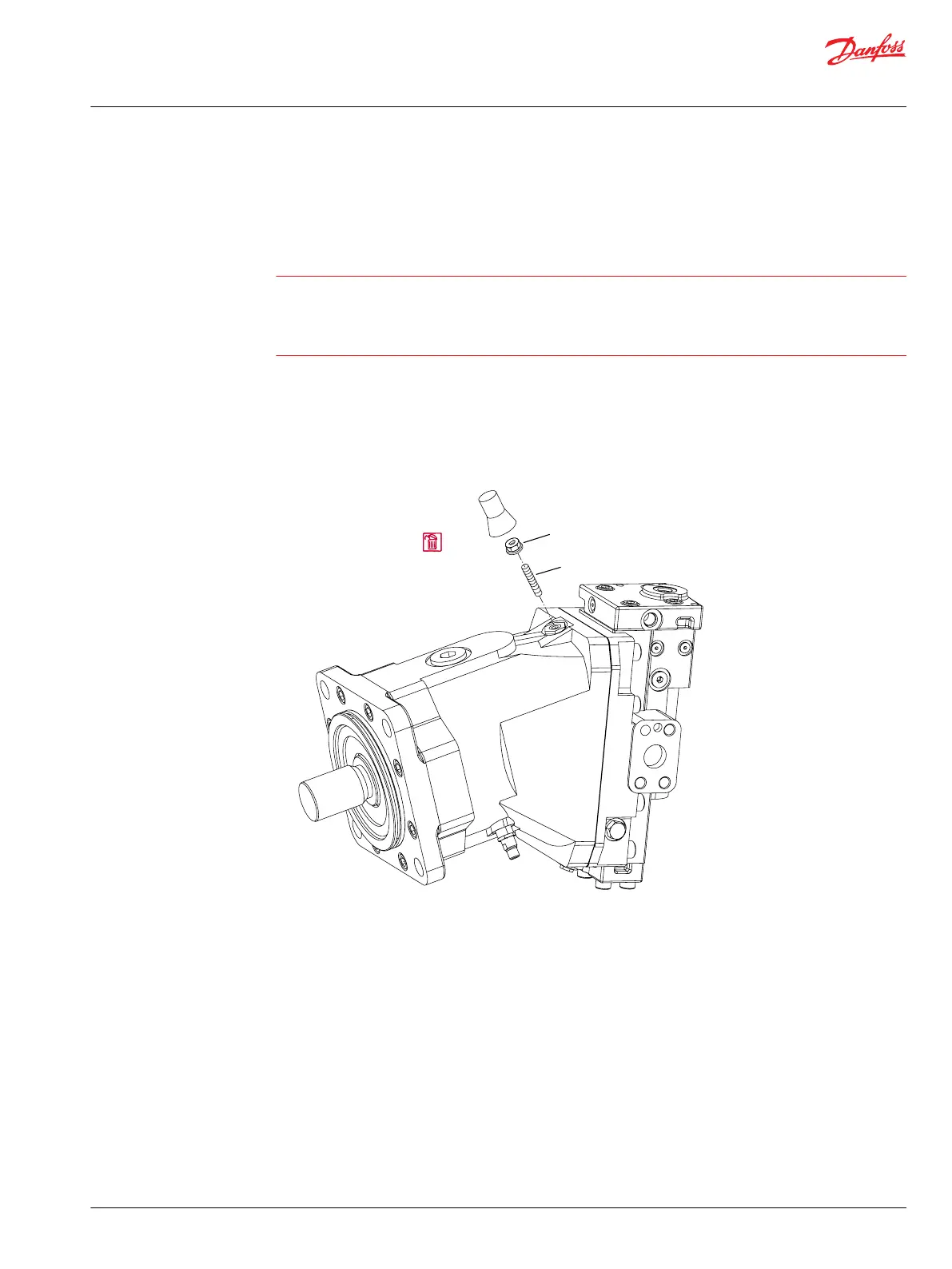

Minimum displacement limiter

Q120

Tamper

resistant

cap

Y20

Y10

P101216E

5.

Loosen the locknut (Y20) on the minimum angle adjustment screw using:

•

a 17 mm hex wrench for 60 cm³ and 80 cm³ motors

or

•

19 mm hex wrench for 110 cm³, 160 cm³ and 250 cm³ motors.

6. Remove the adjustment screw (Y10):

•

using a 5 mm hex wrench for 60 cm³ and 80 cm³ frame size motors

or

•

6 mm hex wrench for 110 cm³, 160 cm³ and 250 cm³ motors.

Inspection

Inspect the adjustment screw.

Service Manual

Series 51 and 51-1 Motors

Minor repair

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 51

Loading...

Loading...