3. After adjusting the plug, torque the locknut to 52 N•m [38 lbf•ft]. Do not overtorque

4. Remove the gauges.

5. Reinstall the port plugs.

Motors with loop flushing defeated, or equipped with an orificed charge pressure relief valve (see

Charge relief valve on page 44) do not require adjustment.

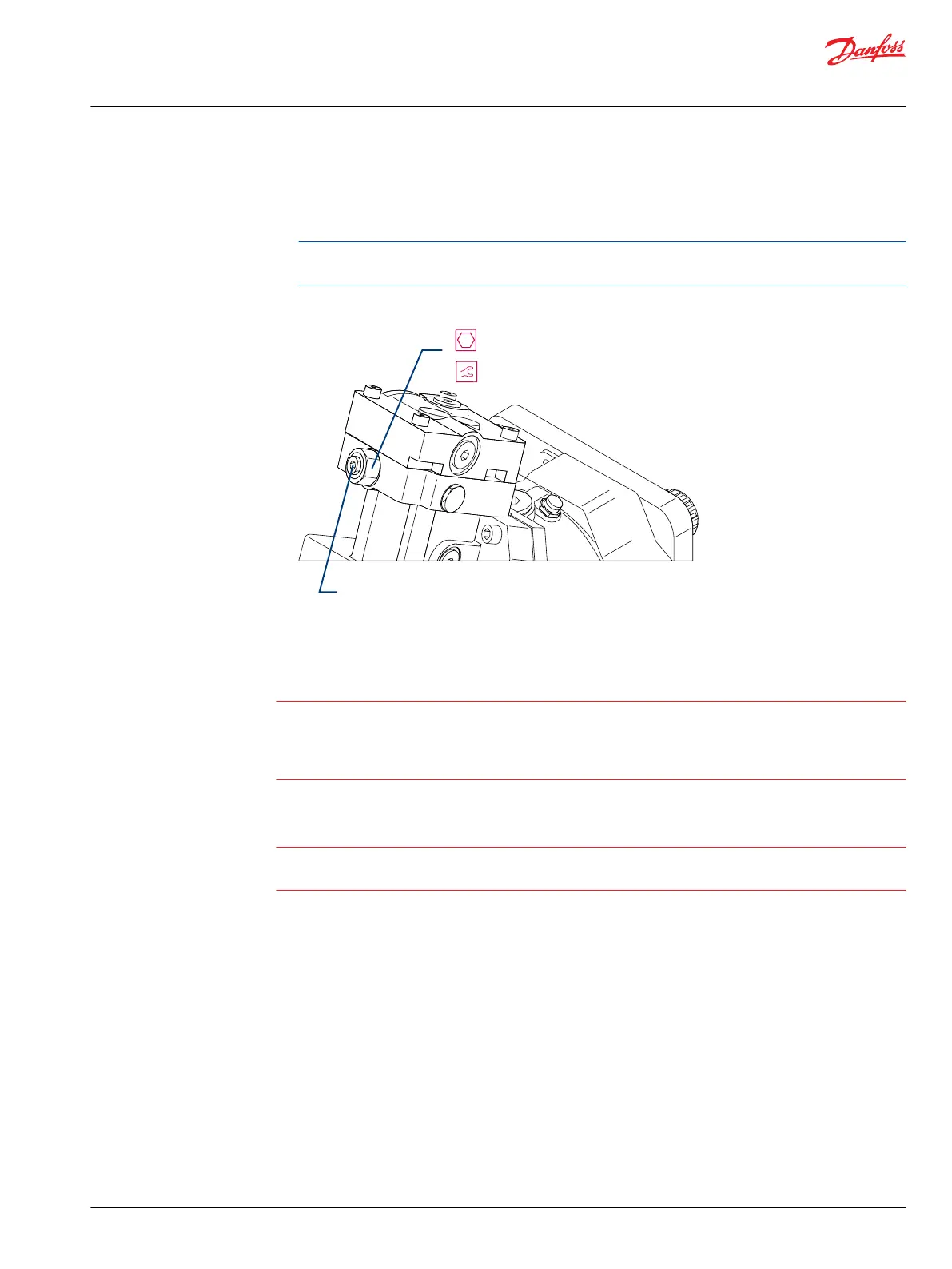

Series 51-1 charge pressure relief valve

1

1

/

16

inch

Adjustment plug

52 Nm [38 lbf•ft]

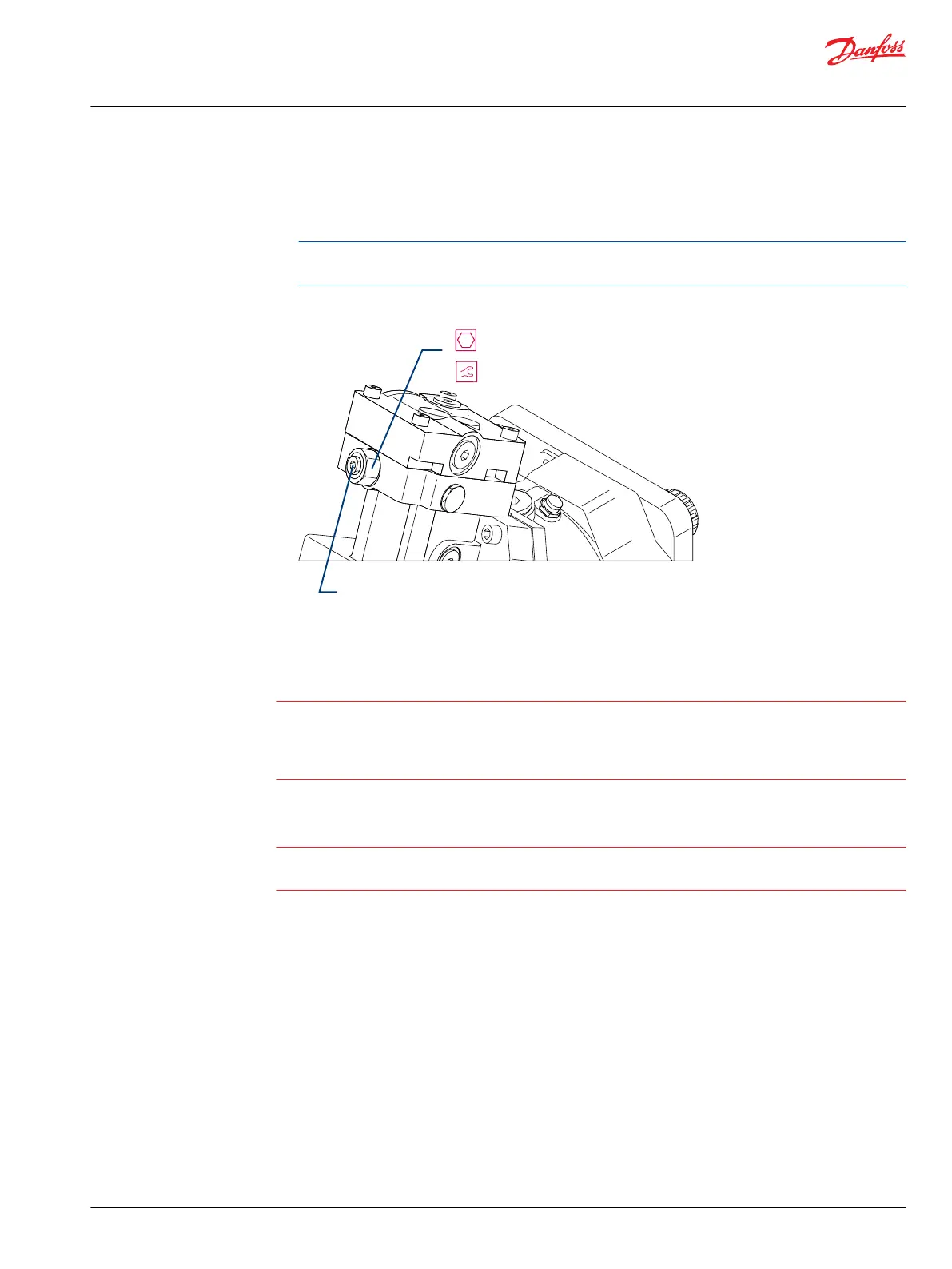

Minimum displacement limiter

Warning

Adjustment of the minimum displacement limiter can result in undesirable or unsafe speed conditions.

Consult with the Original Equipment Manufacturer or your Danfoss representative before changing the

minimum displacement setting. After adjustment, verify minimum displacement setting by using an

appropriate test apparatus.

The factory sets minimum displacement. A tamper-resistant cap covers the adjustment screw.

Caution

To avoid unexpected changes in operating conditions and to prevent external leakage, torque the lock

nut (Y20) after every adjustment.

Detect changes in motor displacement by providing a constant flow of fluid to the motor, while

maintaining the motor at minimum displacement and monitoring the motor output shaft speed. An

increase in displacement will result in a decrease in shaft speed, while a decrease in displacement will

result in an increase in shaft speed.

Adjusting minimum displacement

1. Remove the tamper resistant cap (Q120) from the adjusting screw (Y10). Removing the tamper

resistant cap destroys the locking device.

Service Manual

Series 51 and 51-1 Motors

Adjustments

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 33

Loading...

Loading...