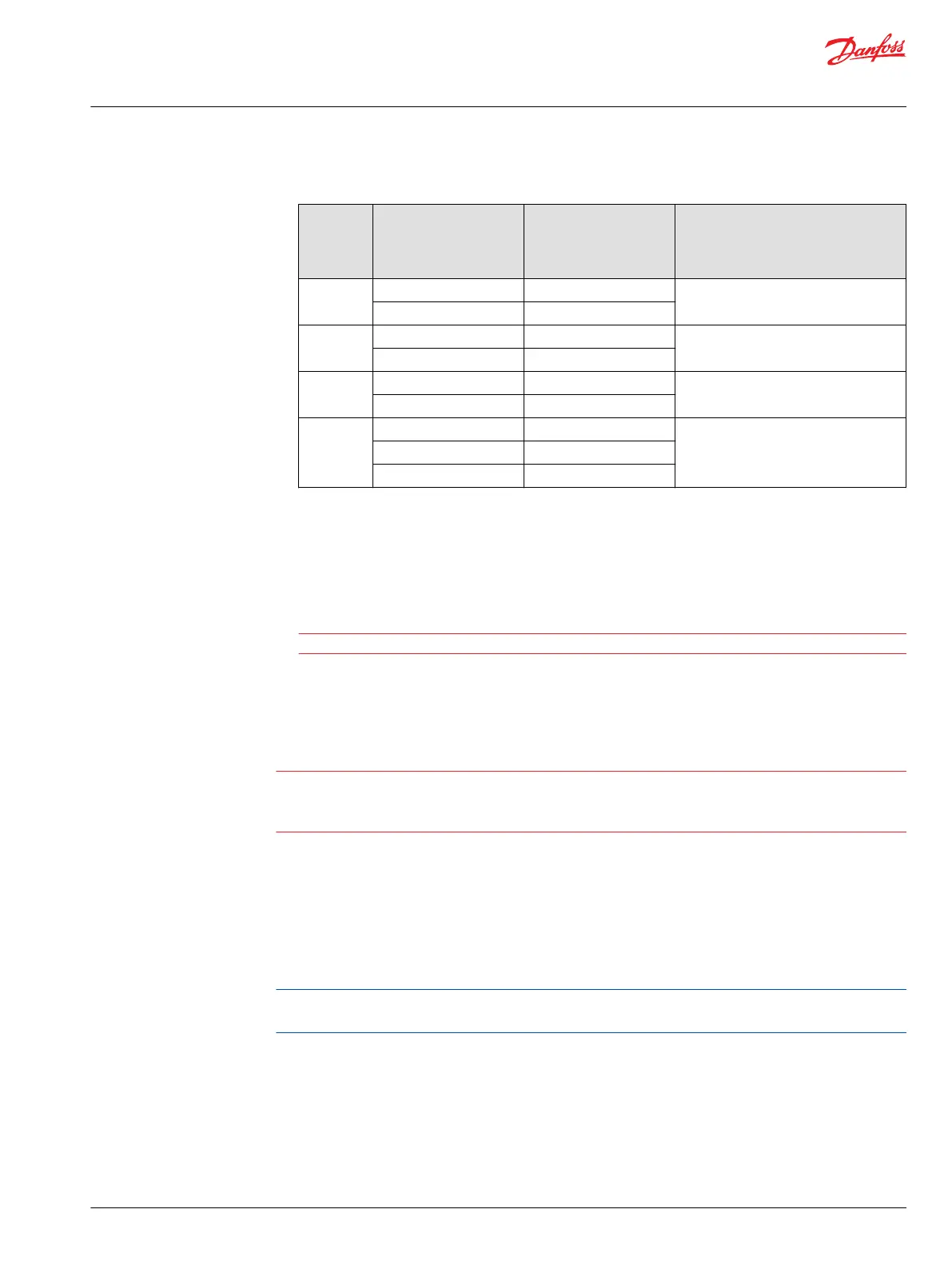

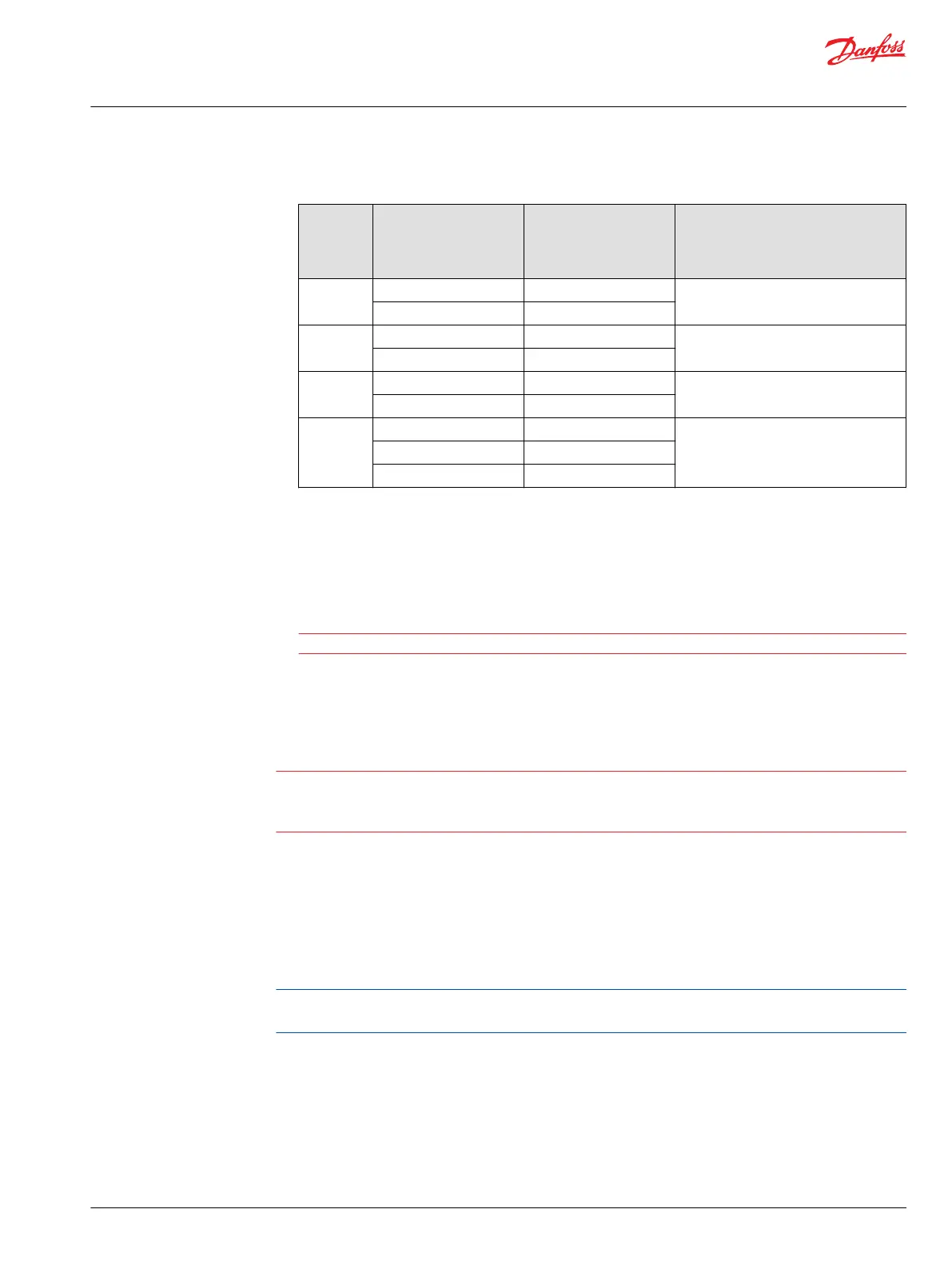

Adjustment screw and displacement (continued)

Frame size Minimum displacement

range cm³ [in³]

Screw size and length

mm [in]

Approximate change in minimum

displacement per revolution of

adjusting screw

cm³/rev [in³/rev]

80 16- 35 [.98 - 2.14] M10 x 65 [2.56] 2.1 [1.3]

36 - 54 [2.20 - 3.20] M10 x 80 [3.15]

110 22 - 46 [1.34 - 2.81] M12 x 70 [2.76] 3.1 [.19]

47 - 74 [2.878 - 4.52] M12 x 80 [3.15]

160 32 - 72 [1.95 - 4.39] M12 x 75 [2.95] 4.0 [.24]

73 - 107 [4.45 - 6.53] M12 x 90 [3.54]

250 50 - 90 [3.05 - 5.49] M12 x 75 [2.95] 6.2 [.38]

91 - 130 [5.55 - 7.93] M12 x 90 [3.54]

131 - 167 [7.99 - 10.19] M12 x 100 [3.94]

6. After adjustment, torque the lock nut on the adjustment screw to:

•

51 N•m [38 lbf•ft] for 060cm³ and 080cm³ motors

or

•

86 N•m [63 lbf•ft] for 110cm³, 160cm³, and 250cm³ motors.

Caution

Do not overtorque locknut

7. Install a new tamper-resistant cap.

Maximum displacement limiter

Warning

Adjusting the maximum displacement limiter can result in undesirable or unsafe speed conditions.

Consult with the Original Equipment Manufacturer or your Danfoss representative before changing the

maximum displacement setting.

Limit the maximum displacement by setting the stroke of the servo piston. A stop screw and spacer is on

the servo piston to limit the maximum displacement of the motor to less than 100%. Spacers are

available in 5% increments.

Limit the displacement by using spacers on the displacement stop screw. When changing the maximum

displacement, you may need a different length screw to accommodate the alternate spacers.

Detect changes in motor displacement by providing a constant flow of fluid to the motor, while

maintaining the motor at maximum displacement and monitoring the motor output shaft speed.

An increase in displacement results in a decrease in shaft speed. A decrease in displacement results in an

increase in shaft speed.

Service Manual

Series 51 and 51-1 Motors

Adjustments

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 35

Loading...

Loading...