5. Continue backing out until the flats are 22° either side of the motor shaft center line (20° to 30° is

acceptable).

6. Hold sensor with a 1/2 inch wrench, torque the locknut using an 11/16 inch wrench to 13 N•m [10

lbf•ft].

Caution

Do not overtorque locknut.

Cartridge units

1. Loosen locknut.

2. Push O-ring toward connector end of sensor unit so that the O-ring does not contact motor housing

during step 3.

3. Thread sensor (CW) into motor housing by hand until bottom end touches the speed ring.

4. Back out (CCW) 2 turns.

5. Turn in or out (whichever is closest) until the orientation notch is 180° away from housing.

6. Hold sensor with a 1/2 inch wrench, torque the locknut using an 11/16 inch wrench to 13 N•m [10

lbf•ft].

Caution

Do not overtorque locknut.

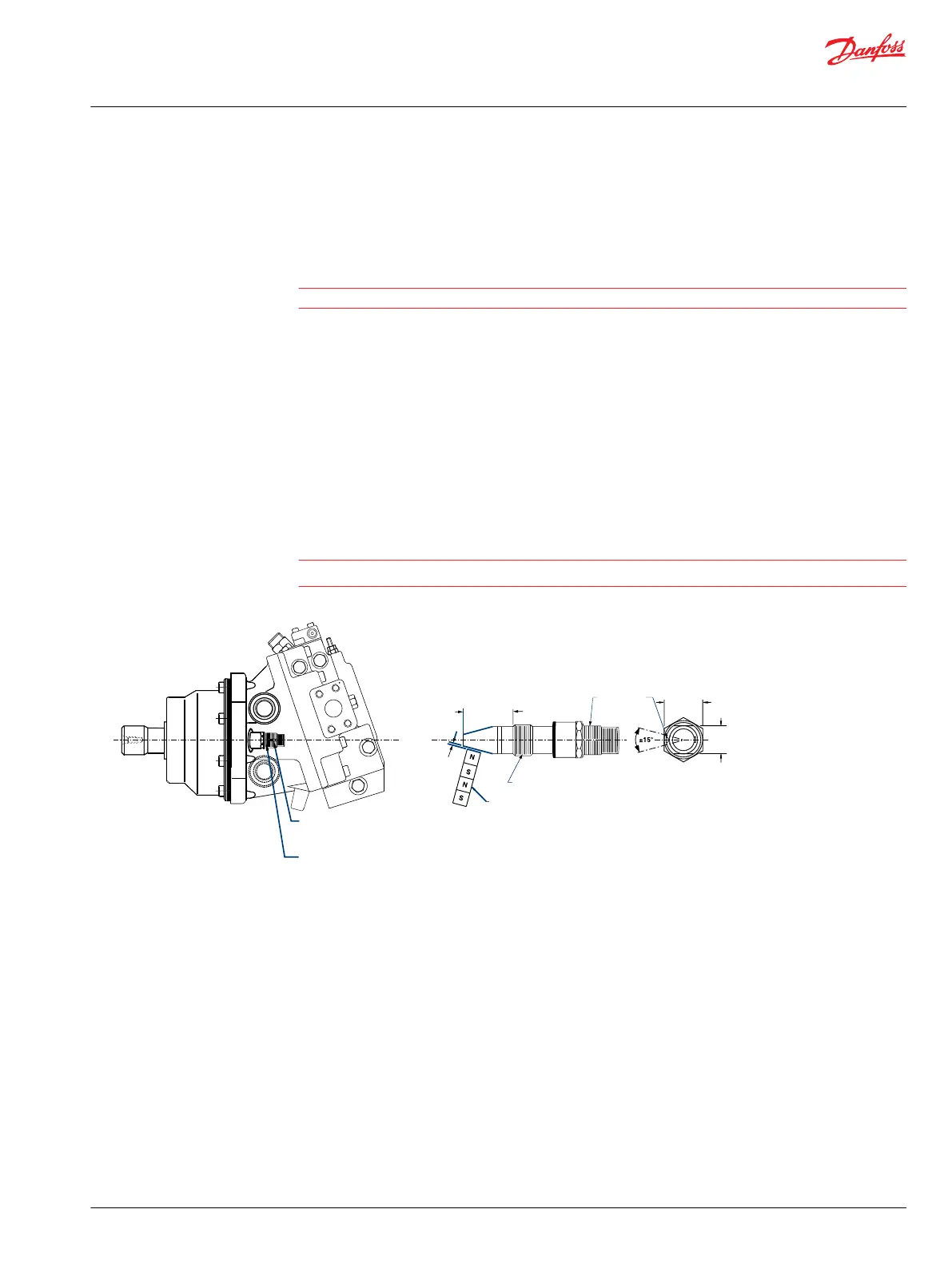

Cartridge model speed sensor

Orientation

notch

Speed sensor

Speed ring

9/16-18UNF-2A thread

Air gap to be

1.52mm [0.060 in.]

max. approximate

2-3 turn of thread

Orientation

notch

22.9 [0.90]

11/16 in.

12.7 [0.50]

flats

P101 333E

Service Manual

Series 51 and 51-1 Motors

Adjustments

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 39

Loading...

Loading...