use a 10 mm internal hex wrench

46 N•m [34 lbf•ft] for 80 cm³, 110 cm³, 160 cm³, 250 cm³ motors

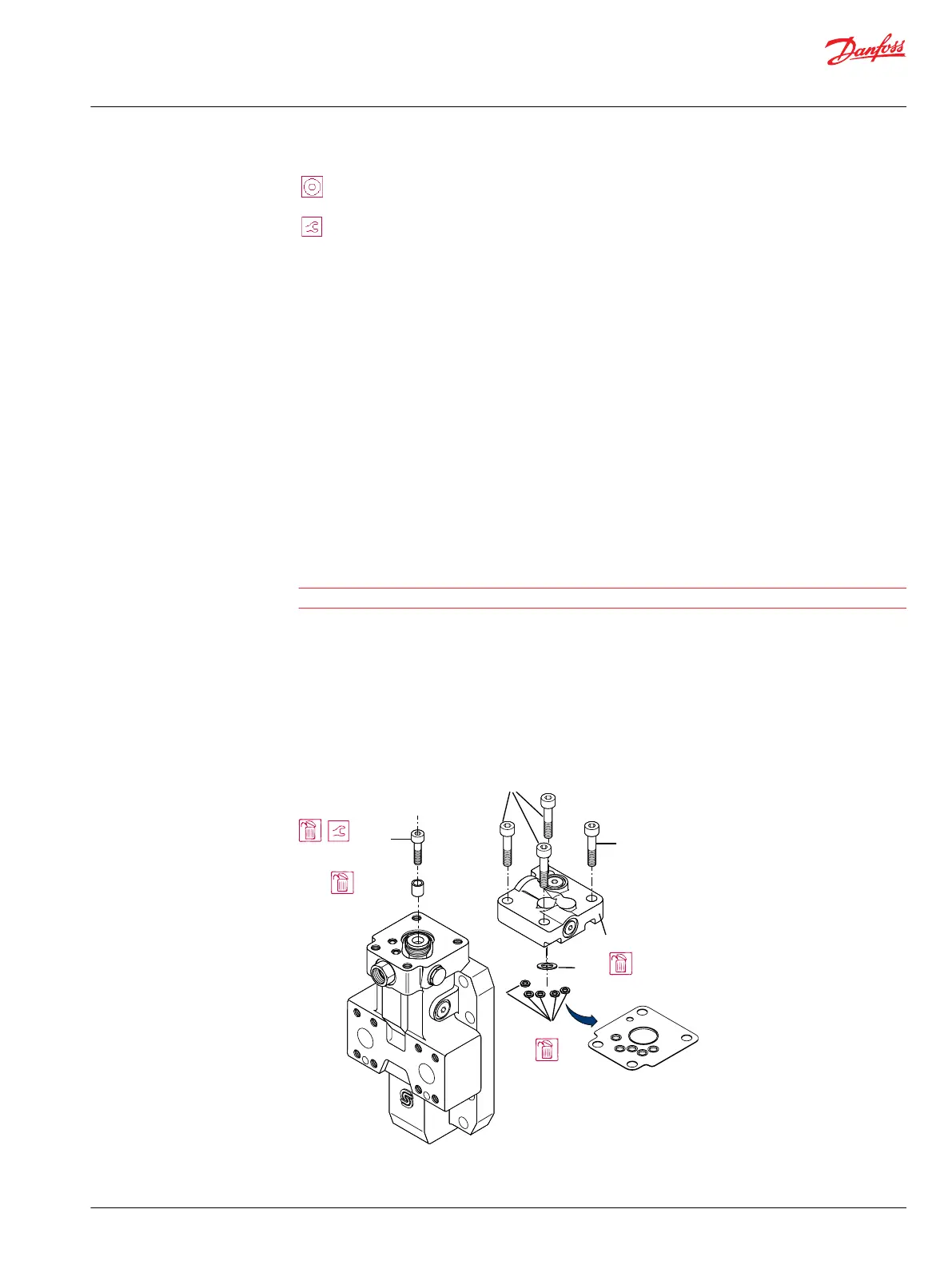

Reassembly

1. Install the stop screw and spacer (if so equipped) to the servo piston end.

2. Torque the stop screw (F10) to:

•

23 N•m [17 lbf•ft] for a 60 cm³ motor using an 8 mm internal hex wrench

•

46 N•m [34 lbf•ft] for 80 cm³, 110 cm³, 160 cm³, and 250 cm³ motors using a 10mm internal hex

wrench.

3. Using petroleum jelly to retain them, install a new O-ring G100 and G36) to the end cap.

4. Install servo cover to (G260) the endcap.

5. Install the 4 screws (items G24).

6. Torque the 4 screws (G24) to:

•

78 N•m [58 lbf•ft] for 60cm³, 80cm³, 110cm³ and 160cm³ motors using an 8 mm internal hex

wrench.

•

110 N•m [81 lbf•ft] for 250cm³ motors using a 10mm internal hex wrench.

Caution

Do not overtorque screws

Maximum angle stop - Series 51-1 motors

Disassembly

1. Remove the 4 screws (M16) retaining the control assembly using an 8mm internal hex wrench.

2. Remove the control assembly.

Series 51-1 maximum displacement limiter

F10*

F20*

M16

M16

G42

G36

Control

P101 222E

or

Legend

F10

Service Manual

Series 51 and 51-1 Motors

Minor repair

©

Danfoss | March 2016 11008567 | AX00000013en-US0202 | 49

Loading...

Loading...