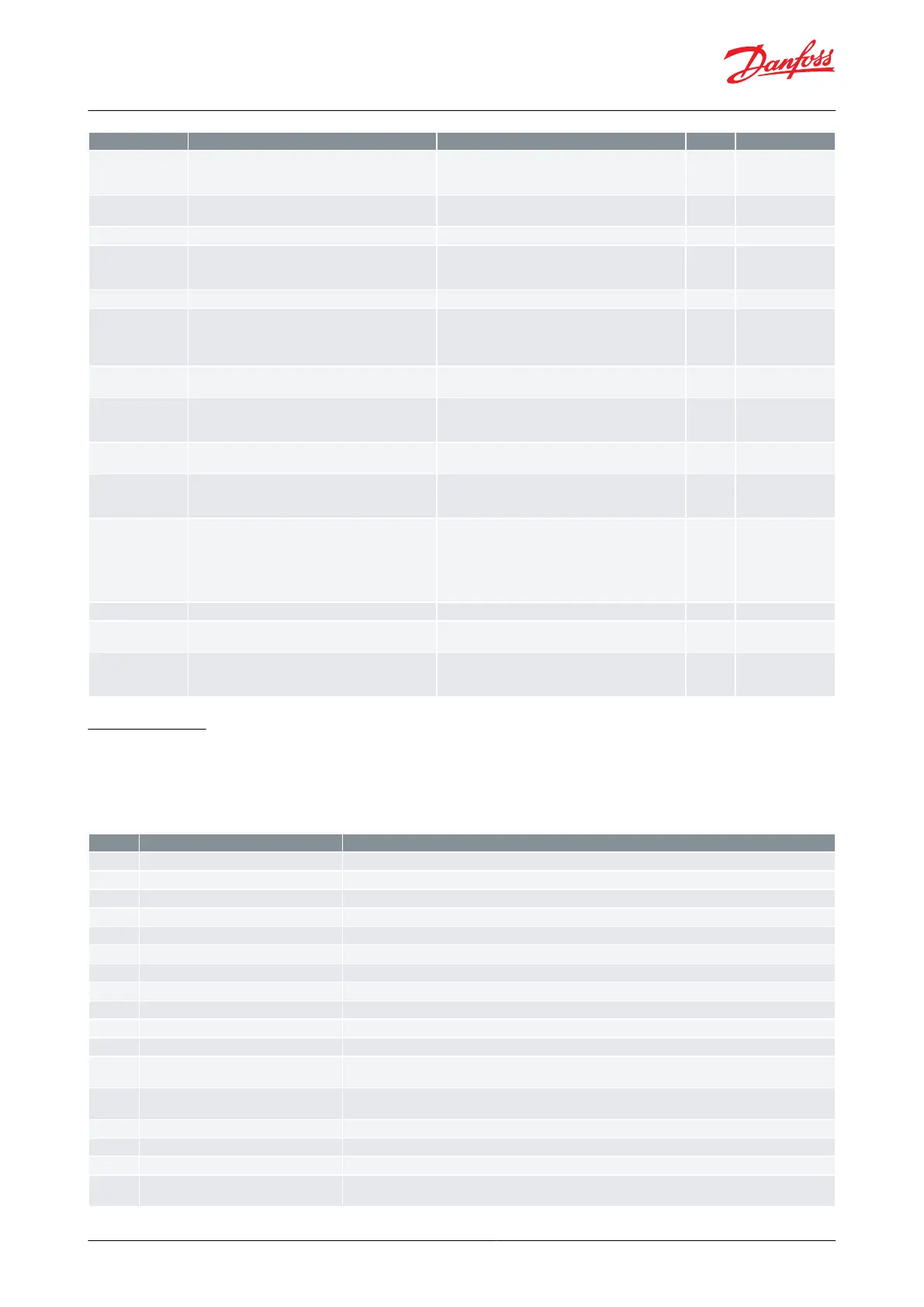

Master control signal used to shut down a case for a

time period. During shutdown there will be no alarm

monitoring

Master control signal that will close the injection

valve

Master control signal that will provide forced cooling

Master control signal for starting a defrost. At adap-

tive defrost the defrost might be skipped if the de-

frost is not needed

Read out the actual state of the defrost

Master control signal used for co-ordinated defrost

control to hold cabinets from returning to normal re-

frigeration after a defrost until all cabinets have termi-

nated defrost

Master control signal used to prevent a defrost start

in a controller.

Master control signal used by system manager to see

if a controller is requesting that the next defrost has

to be carried out

Master control signal for control of light via a data

communication signal from the system manager

Master control signal sending the actual measured

dewpoint from the system manager to the controller

over the network.

Master control signal distributing the condensing

temperature signal to the case controllers that are us-

ing adaptive defrost. At transcritical CO2 sites the re-

ceiver pressure is distributed to the case controllers.

This function needs to be set up in the system man-

ager.

Master control signal that will lock down all Bluetooth

data communication

Required minimum delta temperature across evapo-

rator (S3 - Te) in order to keep the air temperature at

the actual setpoint

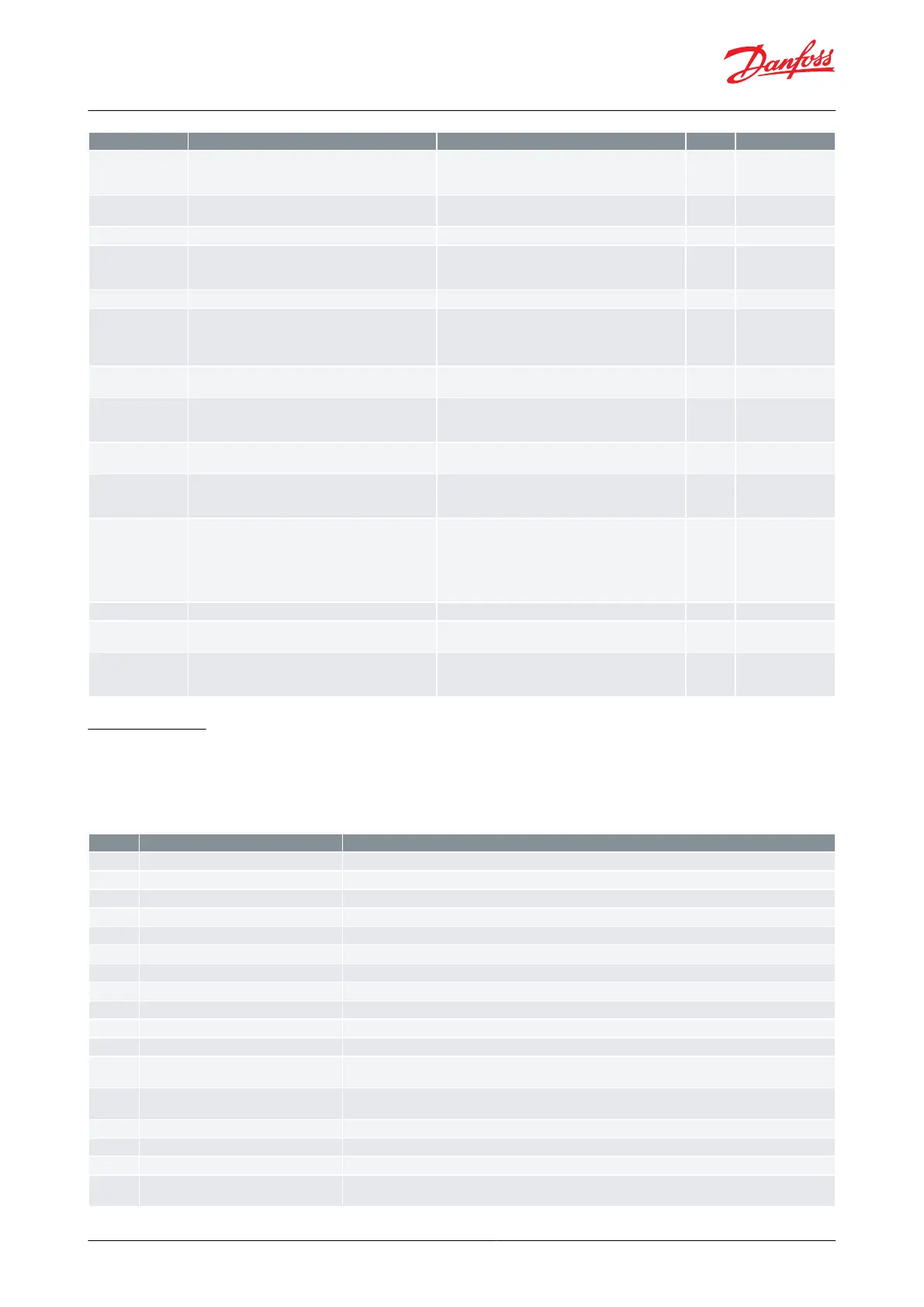

Fault message

In an error situation the alarm LED on the front will be on and the alarm relay will be activated (depending on

priority). If you push the alarm button for 3 seconds you can see the alarm report in the display. (Alarm priorities can

be changed. See Table 40: Alarm relay priorities.) Here are the messages that may appear:

Table 48: Fault message

The controller has a hardware failure

Clock has lost valid time

Pe Evap. pressure A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S2 Gas outlet A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S3 Air ON evap. A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S4 Air OFF evap. A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S5 Evaporator A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S6 product temp. A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S3 Air ON evap. B - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

S5 Evaporator B - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

Humidity sensor - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

The alarm temperature has been above the max alarm limit for a longer time period than the set alarm de-

lay.

The alarm temperature has been below the min alarm limit for a longer time period than the set alarm de-

lay.

The door has been open for a too long time

Max defrost hold time exceeded

The controller has been waiting longer time than permitted after a co-ordinated defrost.

The refrigerant has not been selected hence control can not be initiated

S6 high product temperature A

The S6 Product temperature has been above the max alarm limit for a longer time period than the set alarm

delay.

AK-CC55 Single Coil and Single Coil UI

© Danfoss | Climate Solutions | 2021.02 BC364229688105en-000101 | 62

Loading...

Loading...