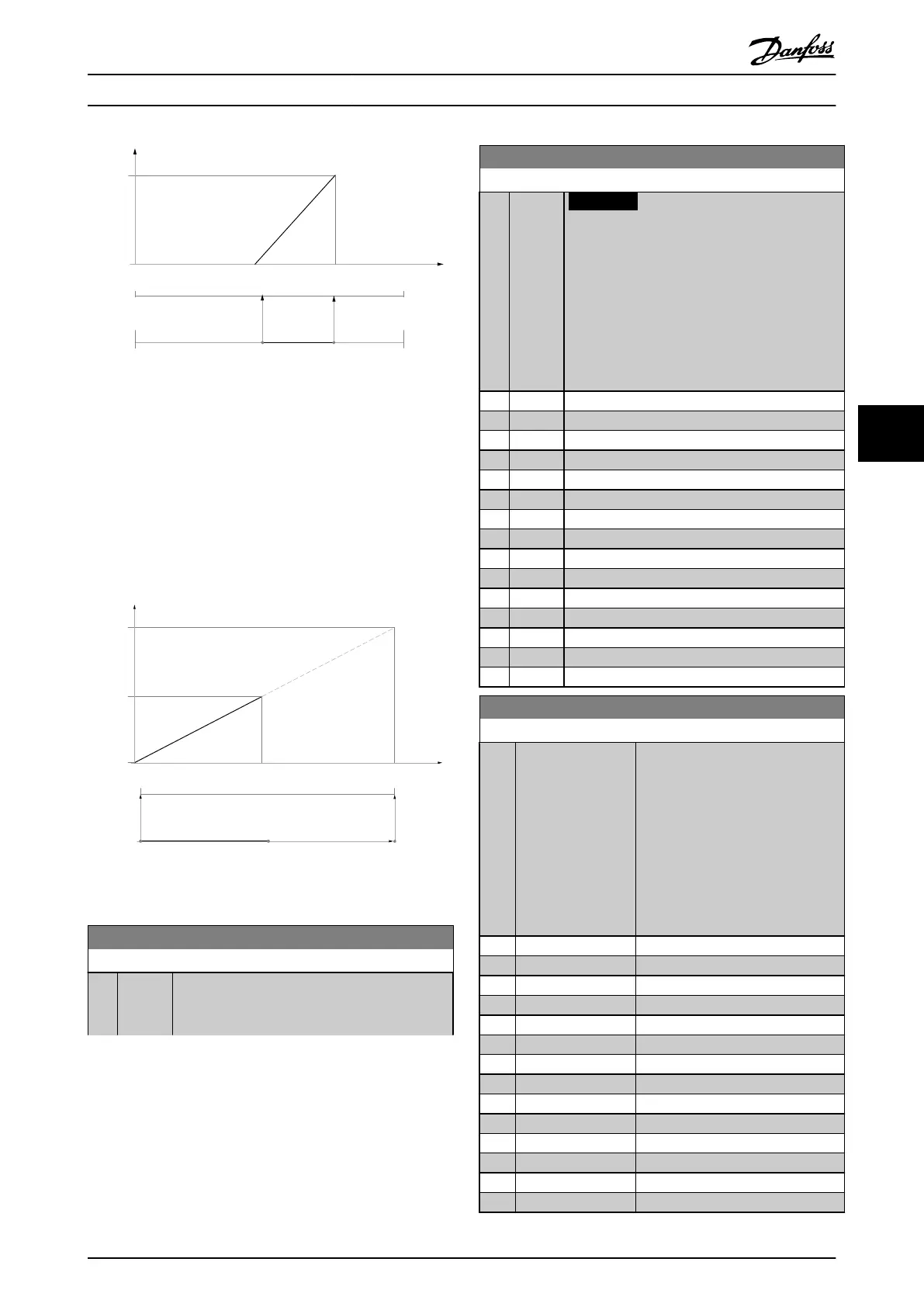

0/4 mA

20 mA

50% 75% 100%0%

0% +100% +200%-200%

130BA856.10

Illustration 6.15

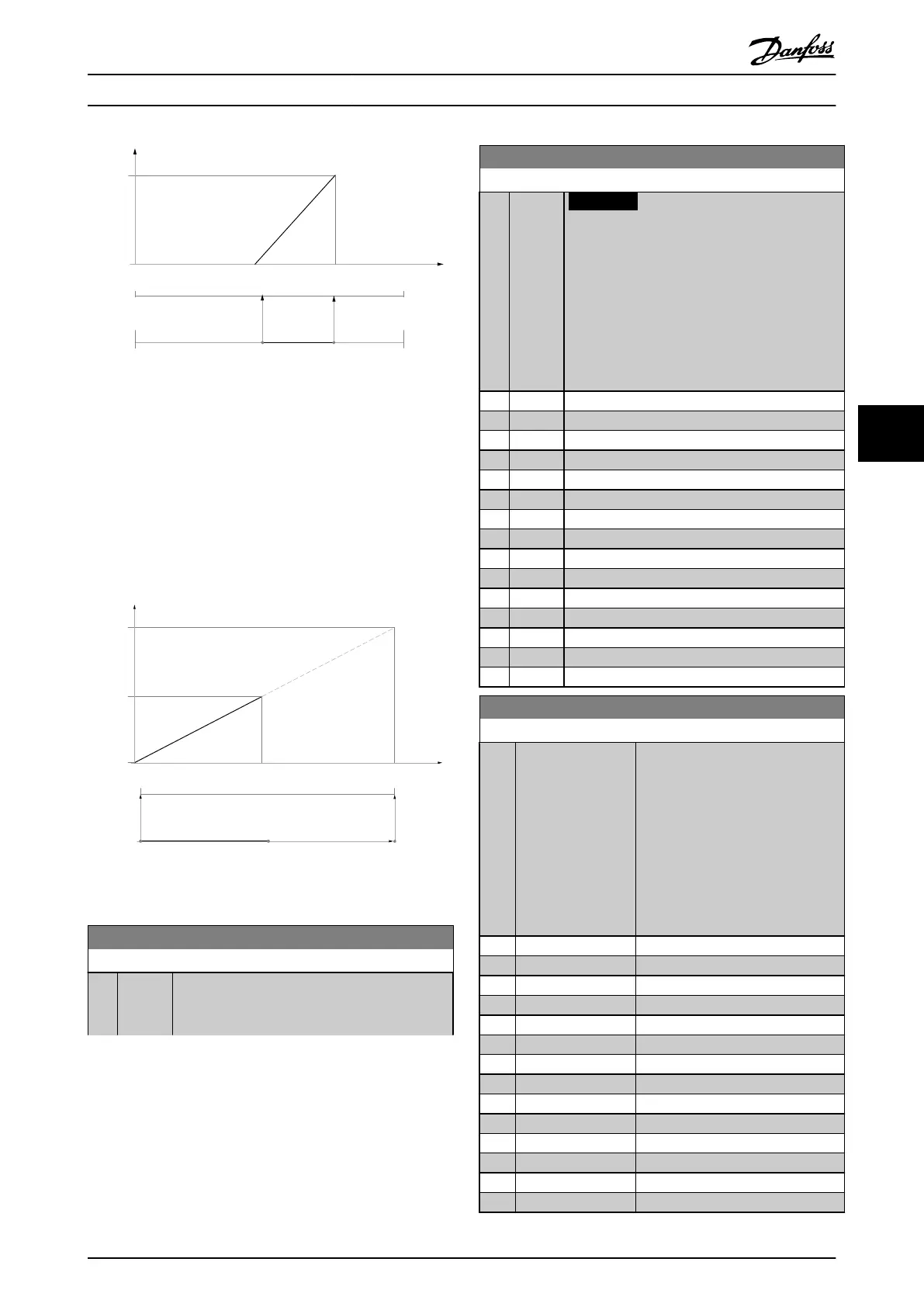

Example 3:

Variable value= REFERENCE, range= Min ref - Max ref

Range needed for output= Min ref (0%) - Max ref (100%),

0-10 mA

Output signal 0 or 4 mA is needed at Min ref - set

parameter 6-51 Terminal 42 Output Min Scale to 0%

Output signal 10 mA is needed at Max ref (100% of range)

- set parameter 6-52 Terminal 42 Output Max Scale to 200%

(20 mA/10 mA x 100%=200%).

20 mA

10 mA

0/4 mA

100% 200%

0%

Max ref Max ref X 20/10Min ref

130BA857.10

Illustration 6.16

14-01 Switching Frequency

Option: Function:

Select the inverter switching frequency. Changing

the switching frequency can help to reduce

acoustic noise from the motor.

14-01 Switching Frequency

Option: Function:

NOTICE

The output frequency value of the

frequency converter must never exceed

1/10 of the switching frequency. When the

motor is running, adjust the switching

frequency in parameter 14-01 Switching

Frequency until the motor is as noiseless as

possible. See also 14-00 Switching Pattern

and the section Derating.

[0] 1.0 kHz

[1] 1.5 kHz

[2] 2.0 kHz

[3] 2.5 kHz

[4] 3.0 kHz

[5] 3.5 kHz

[6] 4.0 kHz

[7] 5.0 kHz

[8] 6.0 kHz

[9] 7.0 kHz

[10] 8.0 kHz

[11] 10.0 kHz

[12] 12.0kHz

[13] 14.0 kHz

[14] 16.0kHz

20-00 Feedback 1 Source

Option: Function:

Up to three different feedback

signals can be used to provide the

feedback signal for the frequency

converter’s PID Controller.

This parameter defines which input

will be used as the source of the

first feedback signal.

Analog input X30/11 and Analog

input X30/12 refer to inputs on the

optional General Purpose I/O board.

[0] No function

[1] Analog Input 53

[2] * Analog Input 54

[3] Pulse input 29

[4] Pulse input 33

[7] Analog Input X30/11

[8] Analog Input X30/12

[9] Analog Input X42/1

[10] Analog Input X42/3

[11] Analog Input X42/5

[15] Analog Input X48/2

[100] Bus Feedback 1

[101] Bus Feedback 2

[102] Bus feedback 3

How to Programme VLT HVAC Drive FC 102 Operating Instructions

MG11F402 - Rev. 2013-12-16 103

6 6

Loading...

Loading...