Overview

This section provides general steps to follow if you observe certain undesirable system conditions. Some

of the items are system specific. Always observe the safety precautions listed in the introduction of this

manual. If standard troubleshooting procedures do not remedy the problem, contact a Danfoss Global

Service Partner.

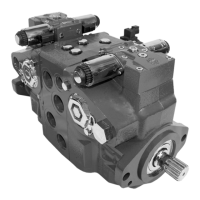

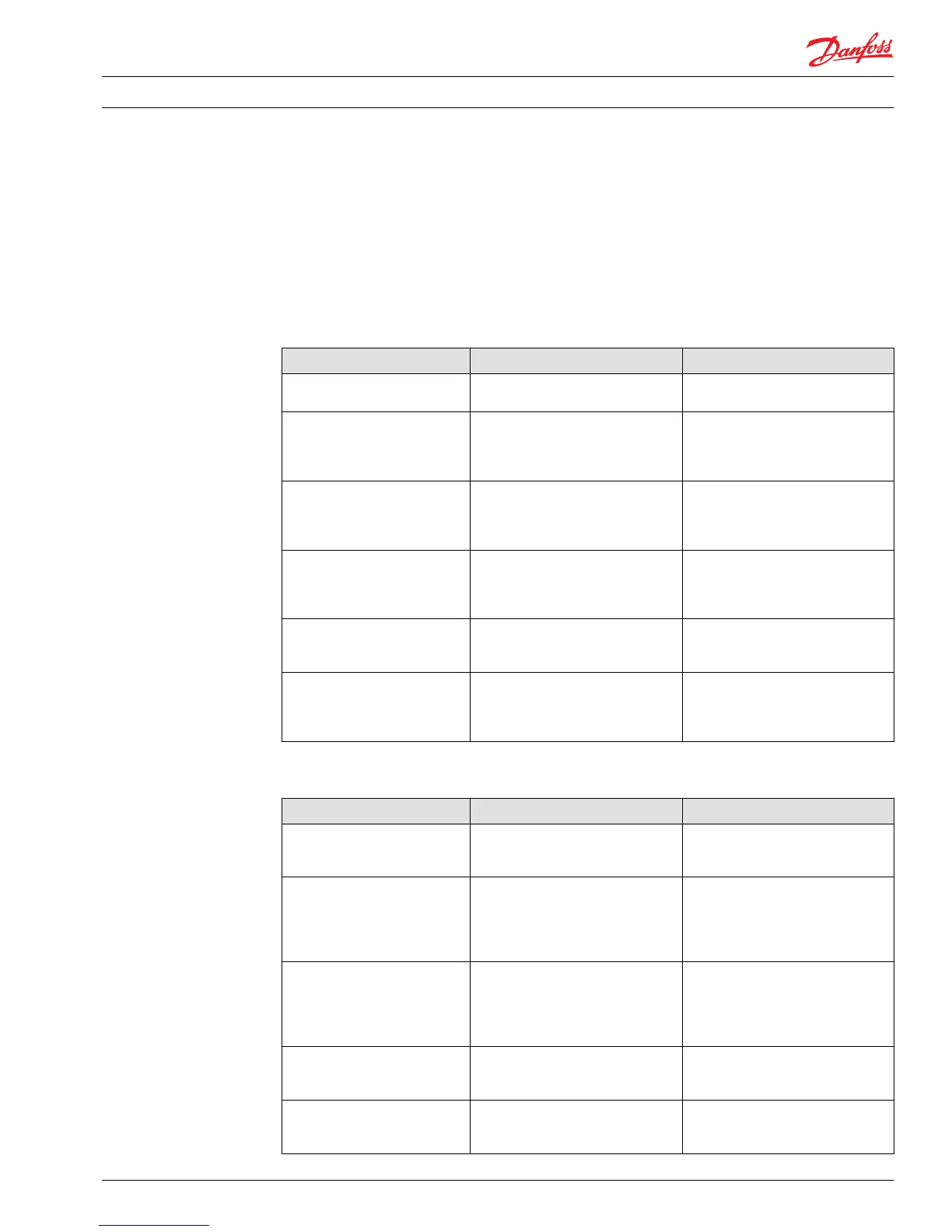

System operating hot

Item Description Action

Oil level in reservoir Insufficient hydraulic fluid will not

meet the cooling demands of system.

Fill the reservoir to the proper level

with clean hydraulic oil.

Heat exchanger (if equipped) The heat exchanger is not sufficiently

cooling the system.

Check the air flow and input air

temperature for the heat exchanger.

Clean, repair, or replace the heat

exchanger as necessary.

Bypass valve A partially activated bypass valve may

result in heat generation within the

system.

Verify that the bypass valve is fully

closed and that the valve is seating

properly. Repair or replace it as

necessary.

SCR (System Check / Relief) Valves A partially activated SCR valve or SCR

valves with relief settings too low may

result in heat generation within the

system.

Verify that the SCR valve is seating

properly and is at the correct relief

setting. Repair or replace it as

necessary.

Oil filters Clogged oil filters may result in an

insufficient supply of cool oil to the

system.

Inspect the oil filters and verify that

they are still operable. Replace them if

necessary.

Machine load Excessive loads or extreme duty cycles

could result in the pump and/ or motor

operating at speeds and pressures

beyond system design limitations.

Verify that the machine is operating

within the parameters for which it was

designed. If necessary, reduce the load

on the machine.

System response is sluggish

Item Description Action

Reservoir oil level There is an insufficient amount of

hydraulic fluid, resulting in an

inadequate supply for the system loop.

Fill the reservoir to the proper level

with clean hydraulic fluid.

Input control signal (linkage,

current, or pressure)

The pump is receiving a faulty control

signal: (MDC - binding or broken

linkage; EDC - faulty or inadequate

electrical signal; HDC - blocked or

incorrectly orificed control lines).

Verify that the input signal is correct

and identical in both directions.

Pump control A damaged pump control or control

spool will not correctly transmit the

control input signal to the pump.

Verify that the pump’s control is

operating properly and that the

control spool is not damaged or worn

and moves freely within its bore. Clean,

repair, or replace it as necessary.

Bypass valve A partially activated bypass valve will

cause cross port leakage.

Verify that the bypass valve is closed

and that the valve is seating properly.

Clean, repair, or replace it as necessary.

SCR (system check / relief) valves One or both of the SCR valves may be

binding within their bores.

Verify that the SCR valves operate

freely. Repair or replace them as

necessary.

Service Manual Series 42 Axial Piston Closed Circuit Pumps

Troubleshooting

520L0638 • Rev 0300 • July 2015 27

Loading...

Loading...