Standard procedures

Remove the pump

Prior to performing certain minor repairs on the Series 42 pump, it may be necessary to remove the

pump from the machine. Chock the vehicle to prohibit movement. Be aware that hydraulic fluid may be

under high pressure and may be hot. Inspect the outside of the pump and fittings for damage.

Keep it clean

Cleanliness is a primary means of assuring satisfactory pump life, on either new or repaired units. Clean

the outside of the pump thoroughly before disassembly. Take care to avoid contamination of the system

ports. Clean parts using a clean solvent wash and air dry.

As with any precision equipment, keep all parts free of foreign materials and chemicals. Protect all

exposed sealing surfaces and open cavities from damage and foreign material. If left unattended, cover

the pump with a protective layer of plastic.

Inspect for system contamination

Inspect the pump for system contamination. If you find contamination, fully disassemble, clean, and

inspect all components of the pump using 11007277 Series 42 Axial Piston Closed Circuit Pumps Repair

Manual in conjunction with this manual.

Replace the O-rings and gaskets

Danfoss recommends you replace all O-rings and gaskets. Lightly lubricate O-rings with clean petroleum

jelly prior to assembly.

Lubricate all moving parts

During reassembly, coat all moving parts with a film of clean hydraulic oil. This will help to lubricate these

parts during start-up. For fluid quality requirements, refer to bulletin 520L0463 Hydraulic Fluids and

Lubricants, Technical Information.

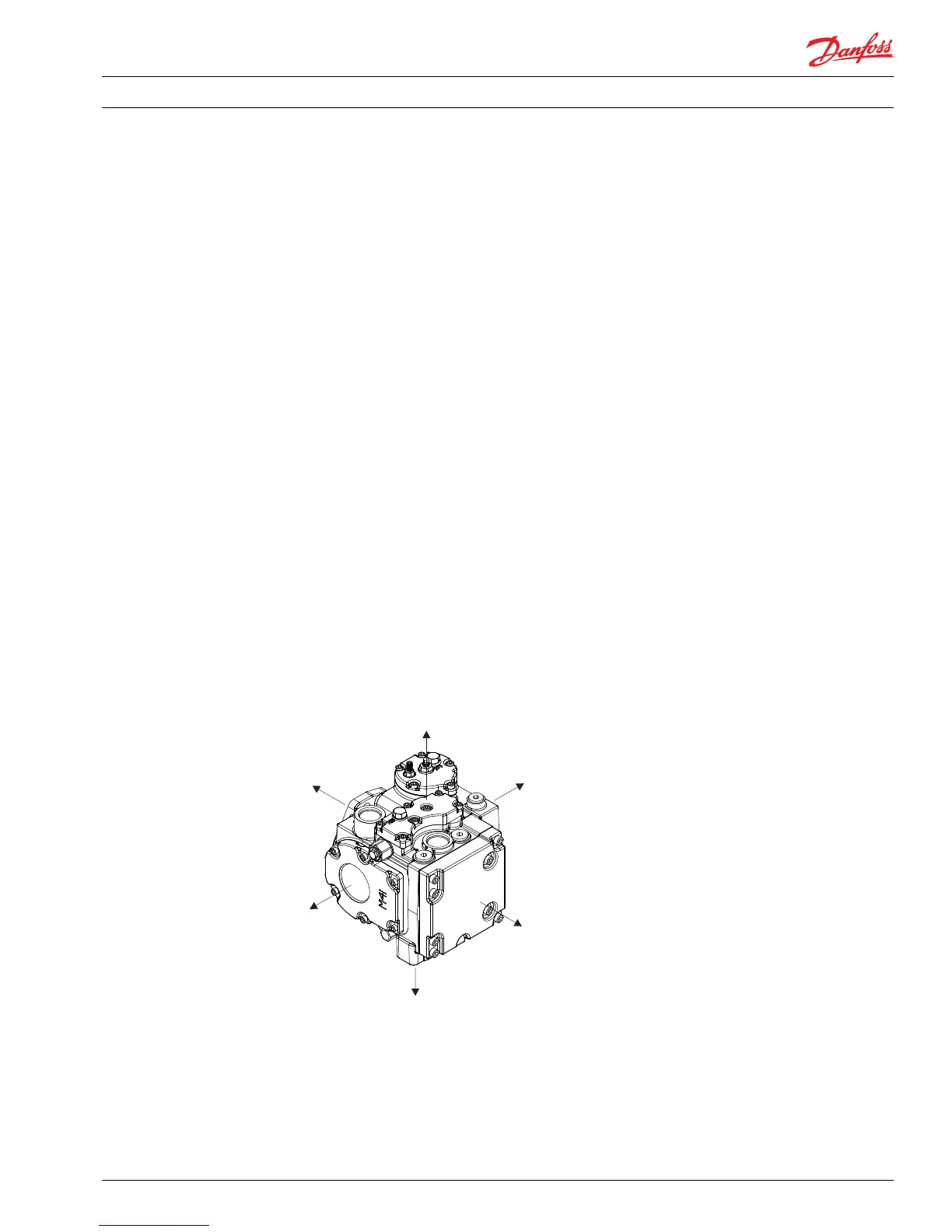

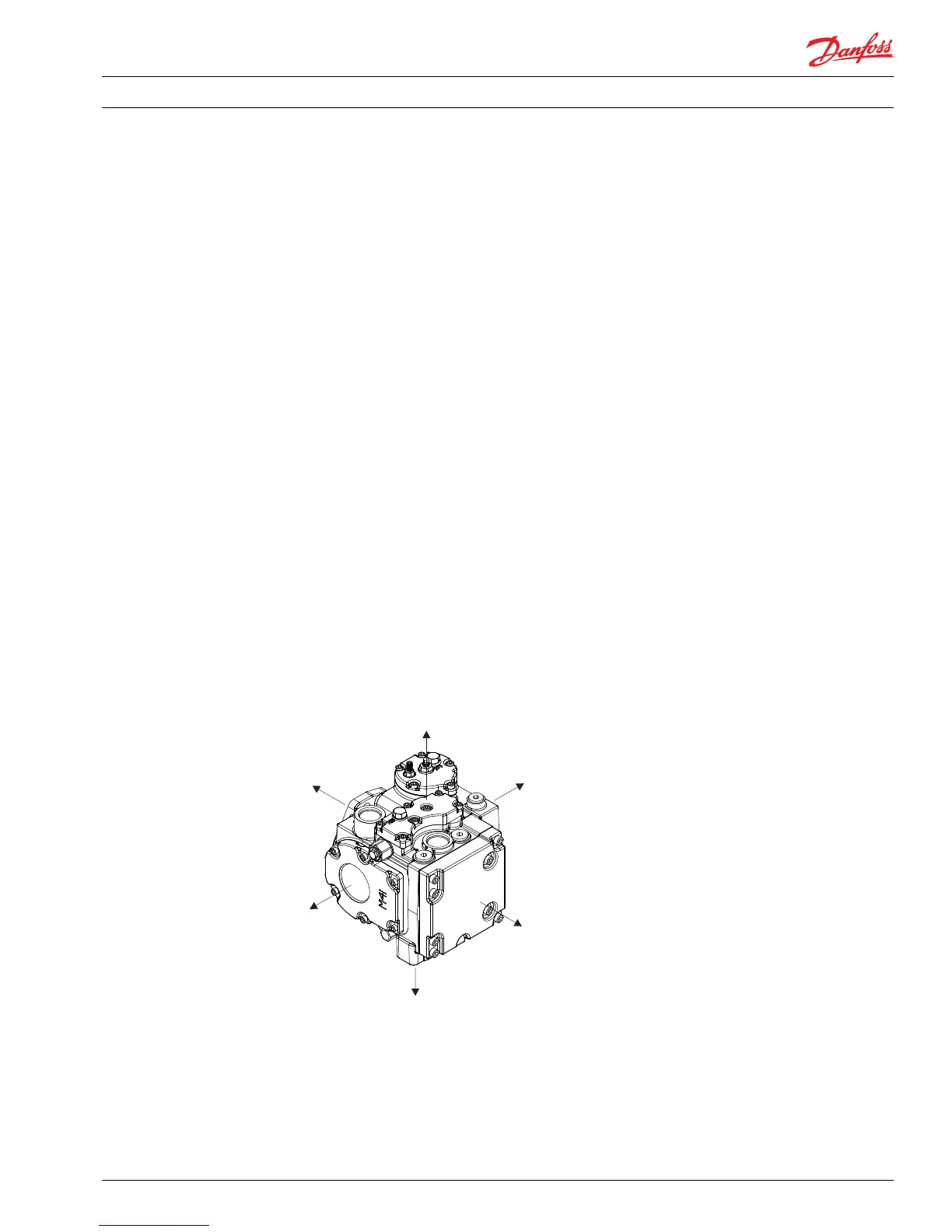

Pump face orientations

Size and torque for plugs and fittings

Plug and fitting sizes appear here. Replace O-rings and lubricate with petroleum jelly whenever a plug is

removed. Torque each as indicated.

Service Manual

Series 42 Axial Piston Closed Circuit Pumps

Minor Repair

520L0638 • Rev 0300 • July 2015 35

Loading...

Loading...