Overview

This section offers instruction on how to perform adjustments to the Series 42 pump. Read through the

entire procedure before beginning any service activity.

Displacement limiter adjustment

Mount the pump on a test stand capable of measuring system flow from the A and B ports.

1. Loosen the displacement limiter seal lock nut (L025), but do not remove it.

2. Start the prime mover and place the pump into full stroke in one direction. Note the system output

flow from either the A or B system port.

3. Adjust the displacement limiter adjustment screw (L020) until the desired output flow is reached.

Turning the displacement limiter adjustment screw clockwise decreases the maximum output flow

setting. Turning the displacement limiter adjustment screw counter clockwise increases the

maximum output flow setting.

Warning

The seal nut lock nut must be retorqued after every adjustment and the limiter screw must have full

thread engagement in the servo piston cover to prevent unexpected changes in operating conditions

and to prevent external leakage during unit operation.

The pump achieves overall maximum flow when the displacement limiter does not contact the servo

piston while the unit is in full stroke.

One full turn of the displacement limiter adjustment screw results in approximate flow output

changes per the table.

4. Once you achieve the proper output flow, torque the displacement limiter seal lock nut (L025) to 23

N•m [17 lbf•ft] while holding the position of the adjustment screw (L020).

5. If required, repeat this procedure using the opposite displacement limiter to set the output flow in

the other direction.

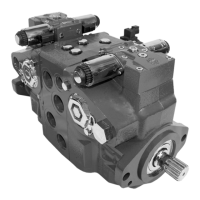

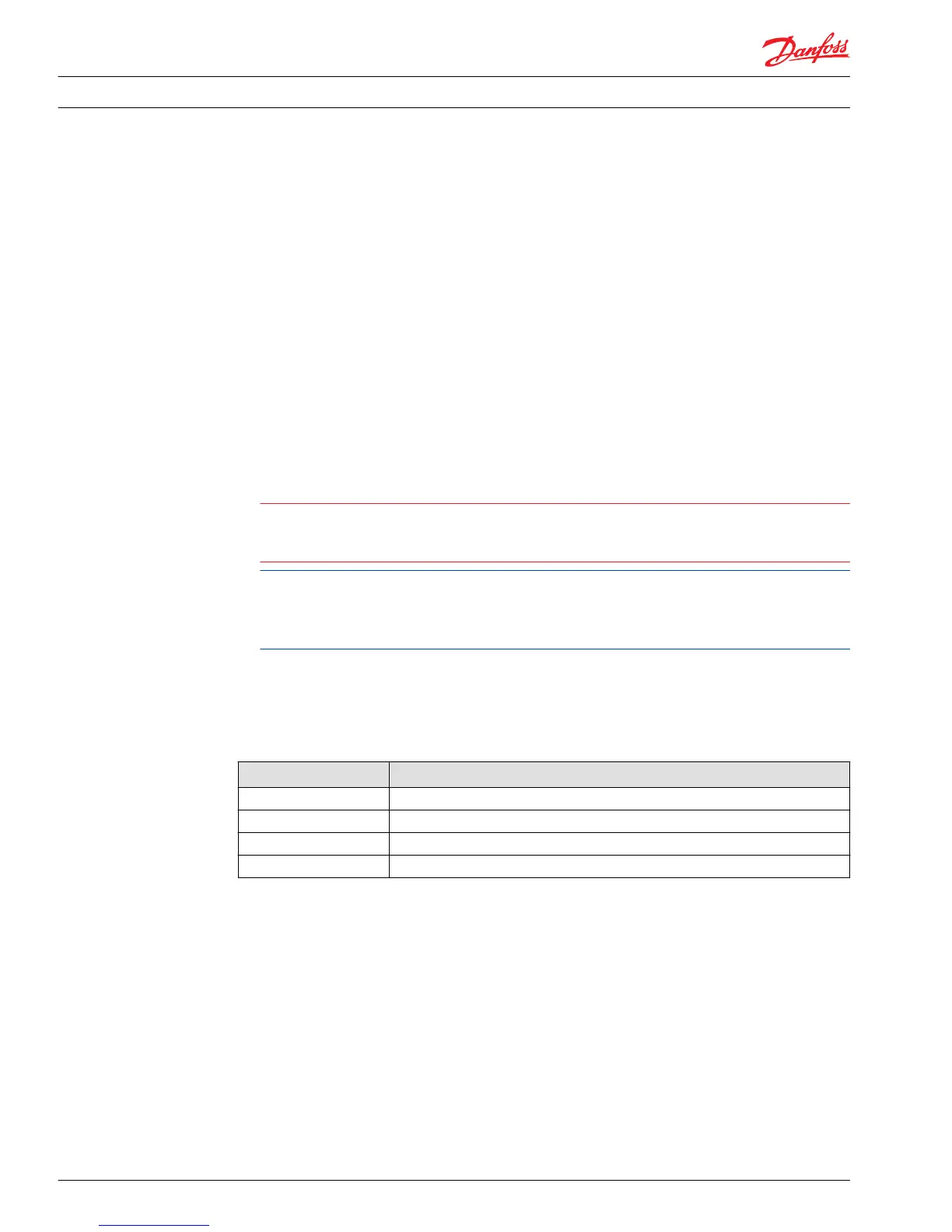

Displacement limiter adjustment

Size Displacement change per turn

28 cm

3

3.6 cm

3

/rev [0.22 in

3

/rev]

32 cm

3

4.1 cm

3

/rev [0.25 in

3

/rev]

41 cm

3

5.0 cm

3

/rev [0.31 in

3

/rev]

51 cm

3

6.2 cm

3

/rev [0.38 in

3

/rev]

Service Manual Series 42 Axial Piston Closed Circuit Pumps

Adjustments

30 520L0638 • Rev 0300 • July 2015

Loading...

Loading...