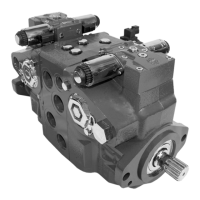

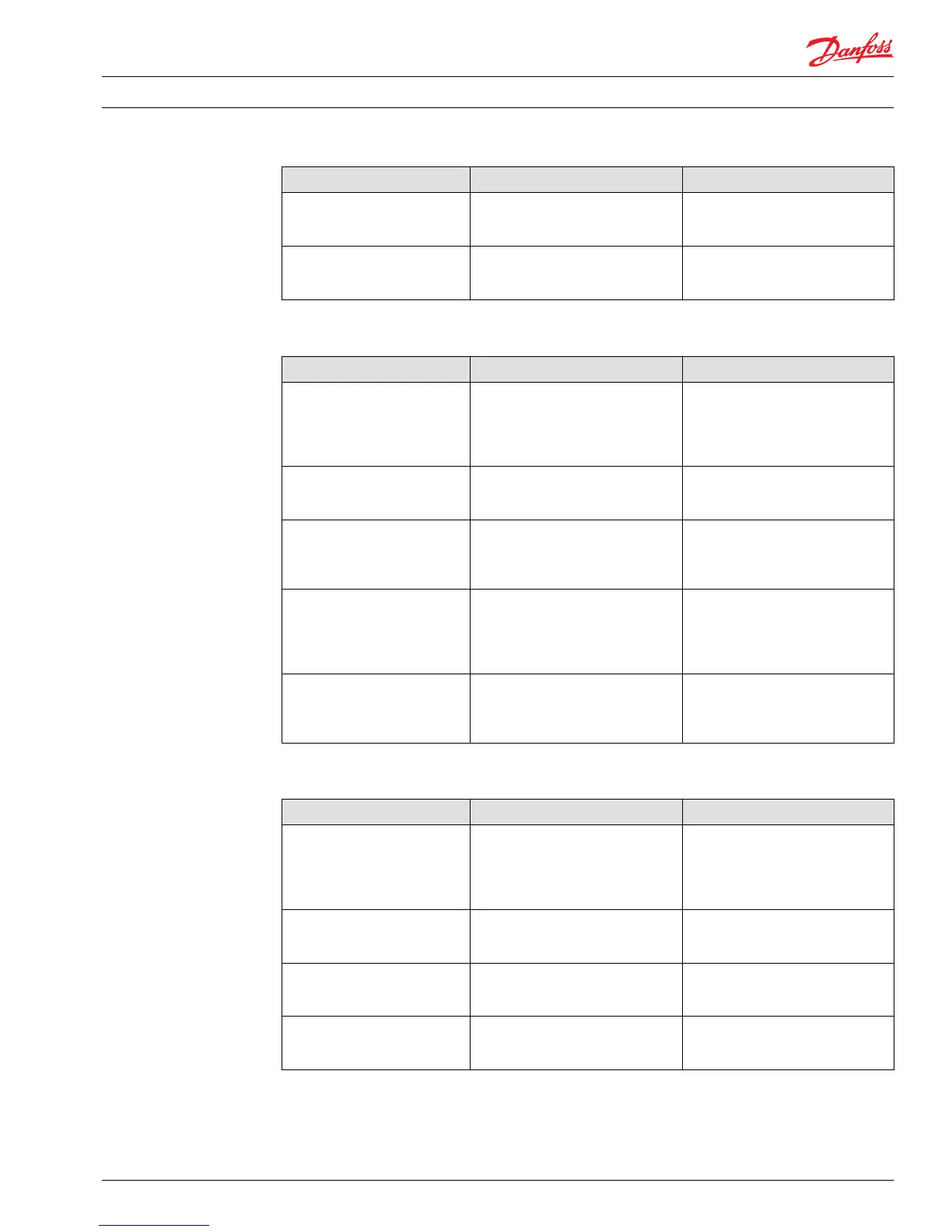

Item Description Action

SCR (system check / relief) valves The SCR valves are malfunctioning or

improperly set.

Verify that the SCR valves are operating

and properly set. Repair or replace

them as necessary.

Displacement limiters Displacement limiters may be

improperly adjusted such that the

servo piston is locked in place.

Verify that the displacement limiters

are adjusted to the proper setting.

System will not operate in one direction

Item Description Action

Input control signal (linkage,

current, or pressure)

The pump is receiving a faulty control

signal: (MDC - binding or broken

linkage; EDC - faulty or inadequate

electrical signal; HDC - blocked or

incorrectly orificed control lines).

Verify that the input signal is correct

and identical in both directions. Adjust,

clean, repair, or replace the control

module as necessary.

SCR (System Check/Relief) valves The SCR valves are malfunctioning or

improperly set.

Verify that the SCR valves are operating

properly. Repair or replace them as

necessary.

Pump control A damaged or biased pump control

may be sending a signal commanding

the pump to stroke only in one

direction.

Verify that the pump’s control is

functioning properly. Repair or replace

it as necessary.

Servo pressure The drain or supply path to one side of

the servo piston may be blocked.

Verify that the servo supply and drain

paths are unobstructed and that any

orifices are of the correct size and free

of debris. Clean or repair them as

necessary.

Displacement limiters (if

equipped)

The displacement limiters may be

improperly adjusted such that the

servo piston is prevented from moving

in one direction.

Verify that the displacement limiters

are adjusted properly.

Neutral difficult or impossible to find

Item Description Action

Input control signal (linkage,

current, or pressure)

The pump is receiving a faulty control

signal: (MDC - binding or broken

linkage; EDC - faulty or inadequate

electrical signal; HDC - blocked or

incorrectly orificed control lines).

Verify that the input signal is correct

and identical in both directions. Adjust,

clean, repair, or replace control module

as necessary.

System pressure With no input signal to the control, a

pressure delta may exist between the

two sides of the working loop.

Readjust pump neutral setting. Refer to

adjustment procedure.

Servo pressure With no input signal to the control, a

pressure delta may exist across the

servo piston.

Readjust the control neutral setting.

Refer to adjustment procedure.

PCP pressure (EDCs only) With no input signal to the control, a

pressure difference may exist across

the control spool.

Replace the EDC.

Service Manual Series 42 Axial Piston Closed Circuit Pumps

Troubleshooting

520L0638 • Rev 0300 • July 2015 29

Loading...

Loading...