1.

1.

-

5.2.2.2.2 PM Parking

This function is the recommended selection for applications where the motor is rotating at slow speed, for example windmilling in

fan applications. Parameter 2-06 Parking Current and parameter 2-07 Parking Time can be adjusted. Increase the factory setting of

these parameters for applications with high inertia.

To activate parking, select [1] Parking in parameter 1-70 Start Mode.

5.2.2.2.3 Application-specific Adjustment when Running VVC+ with PM Motors

VVC+ is the most robust control mode. In most situations, it provides optimum performance without further adjustments. Run a

complete AMA for best performance.

Start the motor at nominal speed. If the application does not run well, check the VVC+ PM settings. See recommendations for vari-

ous applications in

Table 68.

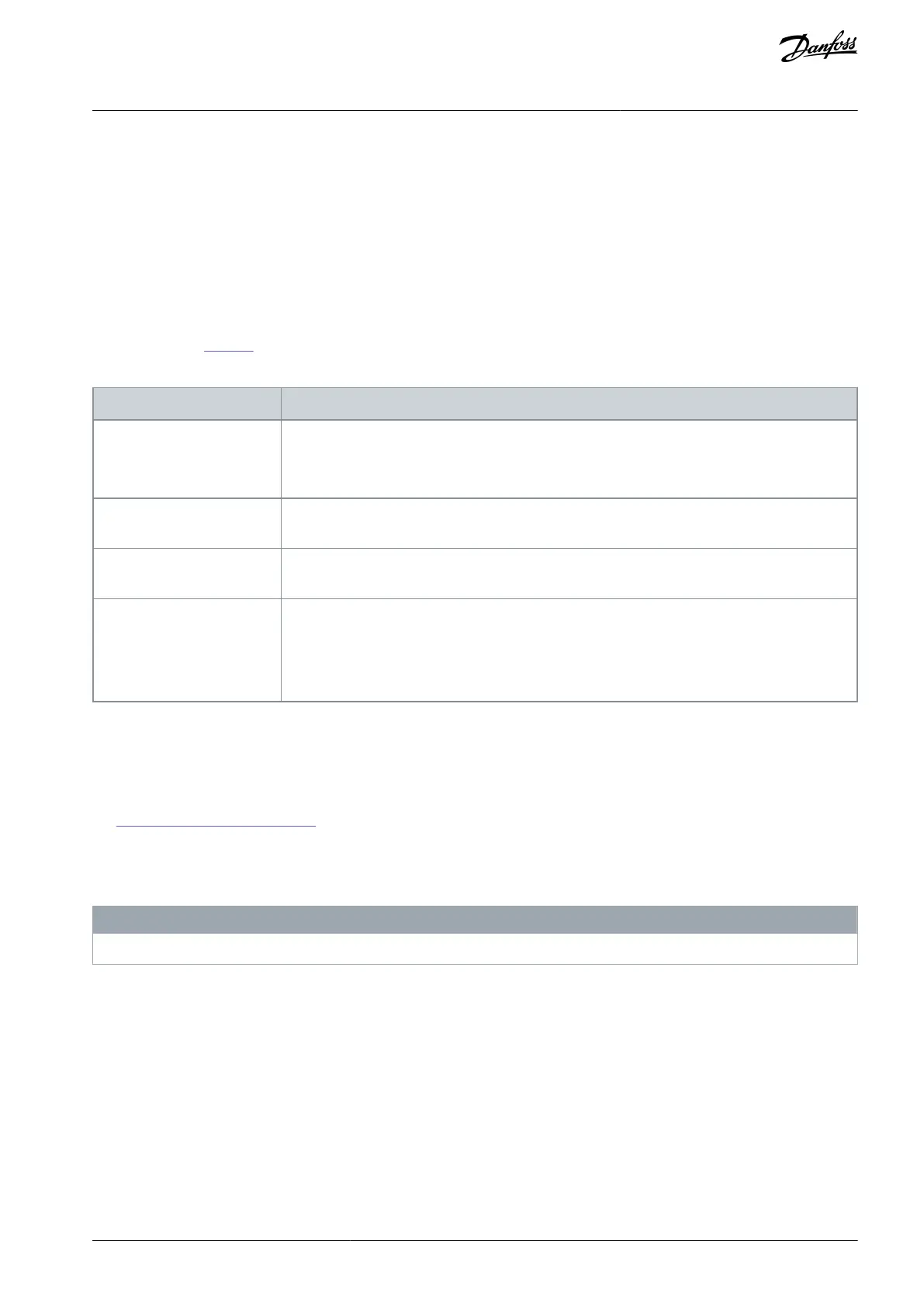

Table 68: Recommendations for Various Applications

Low-inertia applications

I

Load

/I

Motor

<5

Increase parameter 1-17 Voltage Filter Time Const. by factor 5–10.

Reduce parameter 1-14 Damping Gain.

Reduce parameter 1-66 Min.Current at Low Speed (<100%).

Low-inertia applications

50>I

Load

/I

Motor

>5

High-inertia applications

I

Load

/I

Motor

>50

Increase parameter 1-14 Damping Gain, parameter 1-15 Low Speed Filter Time Const., and parame-

ter 1-16 High Speed Filter Time Const.

High load at low speed <30%

(rated speed)

Increase parameter 1-17 Voltage filter time const. Increase parameter 1-66 Min. Current at Low

Speed to adjust the starting torque. 100% current provides nominal torque as starting torque.

This parameter is independent of parameter 30-20 High Starting Torque Time [s] and parameter

30-21 High Starting Torque Current [%]). Working at a current level higher than 100% for a pro-

longed time can cause the motor to overheat.

If the motor starts oscillating at a certain speed, increase parameter 1-14 Damping Gain. Increase the value in small steps. Depending

on the motor, this parameter can be set to 10–100% higher than the default value.

Application-specific adjustment when running flux

Flux control principle is the preferred control principle for optimum shaft performance in dynamic applications. Perform an AMA

because this control mode requires precise motor data. Depending on the application, further adjustments may be required.

See 5.2.2.1 Asynchronous Motor Setup for application-specific recommendations.

5.2.2.3 SynRM Motor Setup with VVC+

This section describes how to set up a SynRM motor with VVC+.

N O T I C E

The SmartStart wizard covers the basic configuration of SynRM motors.

5.2.2.3.1 SynRM Initial Programming

Procedure

Select [5] Sync. Reluctance in parameter 1-10 Motor Construction to activate SynRM motor operation.

5.2.2.3.2 SynRM Programming Motor Data

After performing the initial programming steps, the SynRM motor-related parameters in parameter groups 1-2* Motor Data, 1-3* Adv.

Motor Data, and 1-4* Adv. Motor Data II are active. Find the required motor data on the motor nameplate and in the motor data

sheet.

Procedure

Program in the following order:

AU275636650261en-000101 / 130R0334 | 71Danfoss A/S © 2022.12

Parameter Descriptions

VLT AutomationDrive FC 301/302

Programming Guide

Loading...

Loading...