3.17.4 22-5* End of Curve

The End of Curve conditions occur when a pump is

yielding

a too large volume to ensure the set pressure.

This can occur if there is a leakage in the distribution pipe

system after the pump causing the pump to operate at the

end of the pump characteristic, valid for the max. speed

set in 4-13 Motor Speed High Limit [RPM] or 4-14 Motor

Speed High Limit [Hz].

In case the feed back is 2.5% of the programmed value in

20-14 Maximum Reference/Feedb. (or numerical value of

20-13 Minimum Reference/Feedb. whichever is highest)

below the set point for the desired pressure for a set time

(22-51 End of Curve Delay), and the pump is running with

max. speed set in 4-13 Motor Speed High Limit [RPM] or

4-14 Motor Speed High Limit [Hz], - the function selected in

22-50 End of Curve Function will take place.

It is possible to get a signal on one of the digital outputs

by selecting End of Curve [192] in parameter group 5-3*

Digital Outputs and/or parameter group 5-4* Relays. The

signal will be present, when an End of Curve condition

occurs and the selection in 22-50 End of Curve Function, is

different from Off. The end of curve function can only be

used when operating with the built-in PID controller

(Closed loop in 1-00 Configuration Mode).

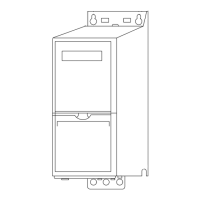

22-50 End of Curve Function

Option: Function:

[0] * Off End of Curve monitoring not active.

[1] Warning The frequency converter will continue to run, but

activate

a End of Curve warning [W94]. A

frequency converter digital output or a serial

communication bus can communicate a warning

to other equipment.

[2] Alarm The frequency converter will stop running and

activate

a End of Curve alarm [A 94]. A frequency

converter digital output or a serial communi-

cation bus can communicate an alarm to other

equipment.

NOTE

Automatic

restart will reset the alarm and start the system

again.

NOTE

Do

not set 14-20 Reset Mode, to [13] Infinite auto reset,

when 22-50 End of Curve Function is set to [2] Alarm. Doing

so will cause the frequency converter to continuously cycle

between running and stopping when a End of Curve

condition is detected.

NOTE

If the frequency converter is equipped with a constant

speed bypass with an automatic bypass function that starts

the bypass if the frequency converter experiences a

persistent alarm condition, be sure to disable the bypass’s

automatic bypass function, if [2] Alarm or [3] Man. Reset

Alarm is selected as the End of Curve Function.

22-51 End of Curve Delay

Range: Function:

10 s* [0 - 600

s]

When an End of Curve condition is detected, a

timer

is activated. When the time set in this

parameter expires, and the End of Curve

condition has been steady in the entire period,

the function set in 22-50 End of Curve Function

will be activated. If the condition disappears

before the timer expires, the timer will be reset.

3.17.5 22-6* Broken Belt Detection

The Broken Belt Detection can be used in both closed and

open

loop systems for pumps, fans and compressors. If the

estimated motor torque is below the broken belt torque

value (22-61 Broken Belt Torque) and the frequency

converter output frequency is above or equal to 15 Hz, the

broken belt function (22-60 Broken Belt Function) is

performed

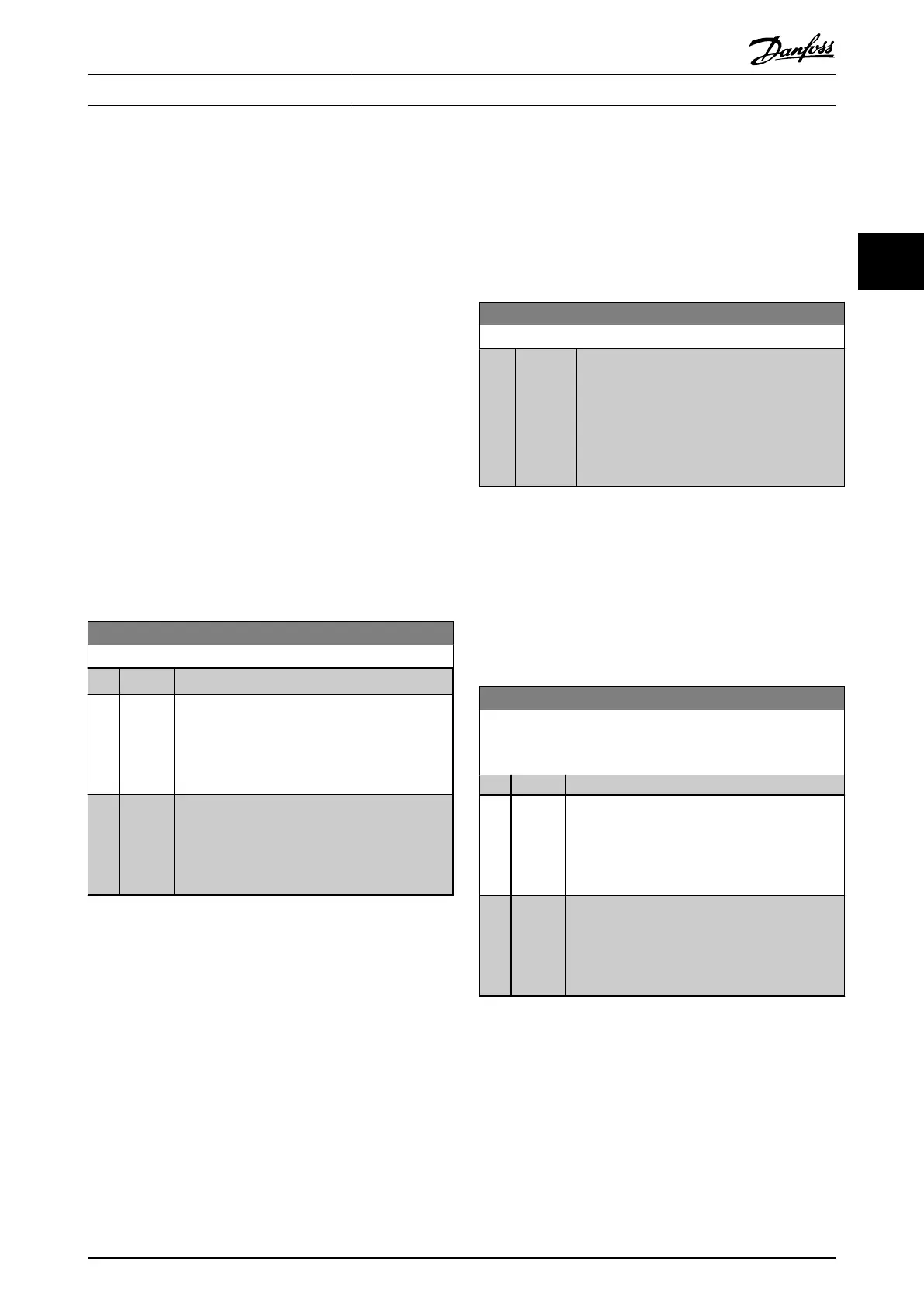

22-60 Broken Belt Function

Selects the action to be performed if the Broken Belt condition is

detected

Option: Function:

[0] * Off

[1] Warning The frequency converter will continue to run, but

activate

a Broken Belt Warning [W95]. A

frequency converter digital output or a serial

communication bus can communicate a warning

to other equipment.

[2] Trip The frequency converter will stop running and

activate

a Broken Belt alarm [A 95]. A frequency

converter digital output or a serial communi-

cation bus can communicate an alarm to other

equipment.

NOTE

Do

not set 14-20 Reset Mode, to [13] Infinite auto reset,

when 22-60 Broken Belt Function is set to [2] Trip. Doing so

will cause the frequency converter to continuously cycle

between running and stopping when a broken belt

condition is detected.

Parameter Description

VLT

®

Refrigeration Drive Programming Guide

MG16H102 - VLT

®

is a registered Danfoss trademark

135

3 3

Loading...

Loading...