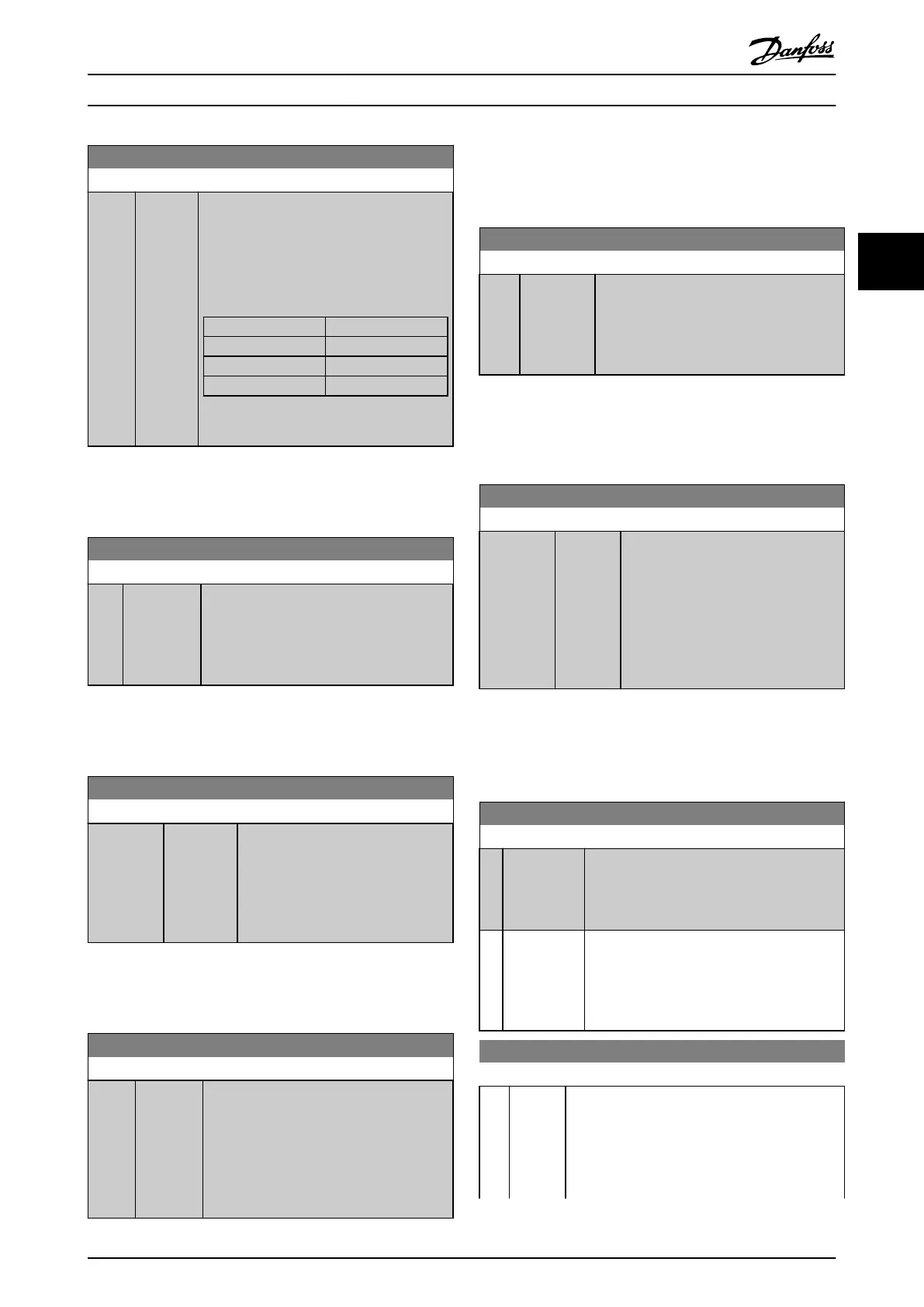

1-61 High Speed Load Compensation

Range: Function:

100 %* [0 - 300

%]

Enter the % value to compensate voltage in

relation

to load when the motor is running

at high speed and obtain the optimum U/f

characteristic. The motor size determines the

frequency range within which this parameter

is active.

Motor size [kW] Change-over [Hz]

0.25-7.5 > 10

11-45 < 5

55-550 < 3-4

Table 3.8

NOTE

1-61

High Speed Load Compensation will not have effect

when 1-10 Motor Construction = [1] PM, non salient SPM.

1-62 Slip Compensation

Range: Function:

0 %* [-500 - 500

%]

Enter the % value for slip compensation, to

compensate

for tolerances in the value of

n

M,N

. Slip compensation is calculated

automatically, i.e. on the basis of the rated

motor speed n

M,N

.

NOTE

1-62

Slip Compensation will not have effect when

1-10 Motor Construction = [1] PM, non salient SPM.

1-63 Slip Compensation Time Constant

Range: Function:

Size related* [0.05 - 5 s] Enter the slip compensation reaction

speed. A high value results in slow

reaction, and a low value results in

quick reaction. If low-frequency

resonance problems arise, use a

longer time setting.

NOTE

1-63

Slip Compensation Time Constant will not have effect

when 1-10 Motor Construction = [1] PM, non salient SPM.

1-64 Resonance Dampening

Range: Function:

100 %* [0 - 500

%]

Enter the resonance dampening value. Set

1-64

Resonance Dampening and

1-65 Resonance Dampening Time Constant to

help eliminate high-frequency resonance

problems. To reduce resonance oscillation,

increase the value of 1-64 Resonance

Dampening.

NOTE

1-64

Resonance Dampening will not have effect when

1-10 Motor Construction = [1] PM, non salient SPM.

1-65 Resonance Dampening Time Constant

Range: Function:

5 ms* [5 - 50 ms]

Set 1-64

Resonance Dampening

and

1-65 Resonance Dampening Time Constant to

help eliminate high-frequency resonance

problems. Enter the time constant that

provides the best dampening.

NOTE

1-65 Resonance Dampening Time Constant will not have

effect when 1-10 Motor Construction = [1] PM, non salient

SPM.

1-66 Min. Current at Low Speed

Range: Function:

Size related* [ 1 - 200

%]

Enter

the minimum motor current at

low speed.

Increasing this current improves

developed motor torque at low speed.

Low speed is here defined as speeds

below 6% of the Nominal Speed of

Motor (1-25 Motor Nominal Speed) in

VVC

plus

PM Control

NOTE

1-66

will not have affect if 1-10 =[0]

3.3.8 1-7* Start Adjustments

1-70 PM Start Mode

Option: Function:

[0] Rotor

Detection

Suitable for all applications where the motor

is

known to be standing still when starting

(e.g. conveyors, pumps and non wind milling

fans).

[1] Parking If the motor turns at a slight speed (i.e. lower

than

2-5% of the nominal speed) e.g. due to

fans with light wind milling, select [1] Parking

and adjust 2-06 Parking Current and

2-07 Parking Time accordingly.

1-71 Start Delay

Range: Function:

0 s* [0.0 -

120.0 s]

This parameter refers to the start function

selected in 1-72 Start Function.

Enter the time delay required before commencing

acceleration.

The parameter is also used for delayed start of

compressor functionality in Injection Control.

Parameter Description

VLT

®

Refrigeration Drive Programming Guide

MG16H102 - VLT

®

is a registered Danfoss trademark

43

3 3

Loading...

Loading...