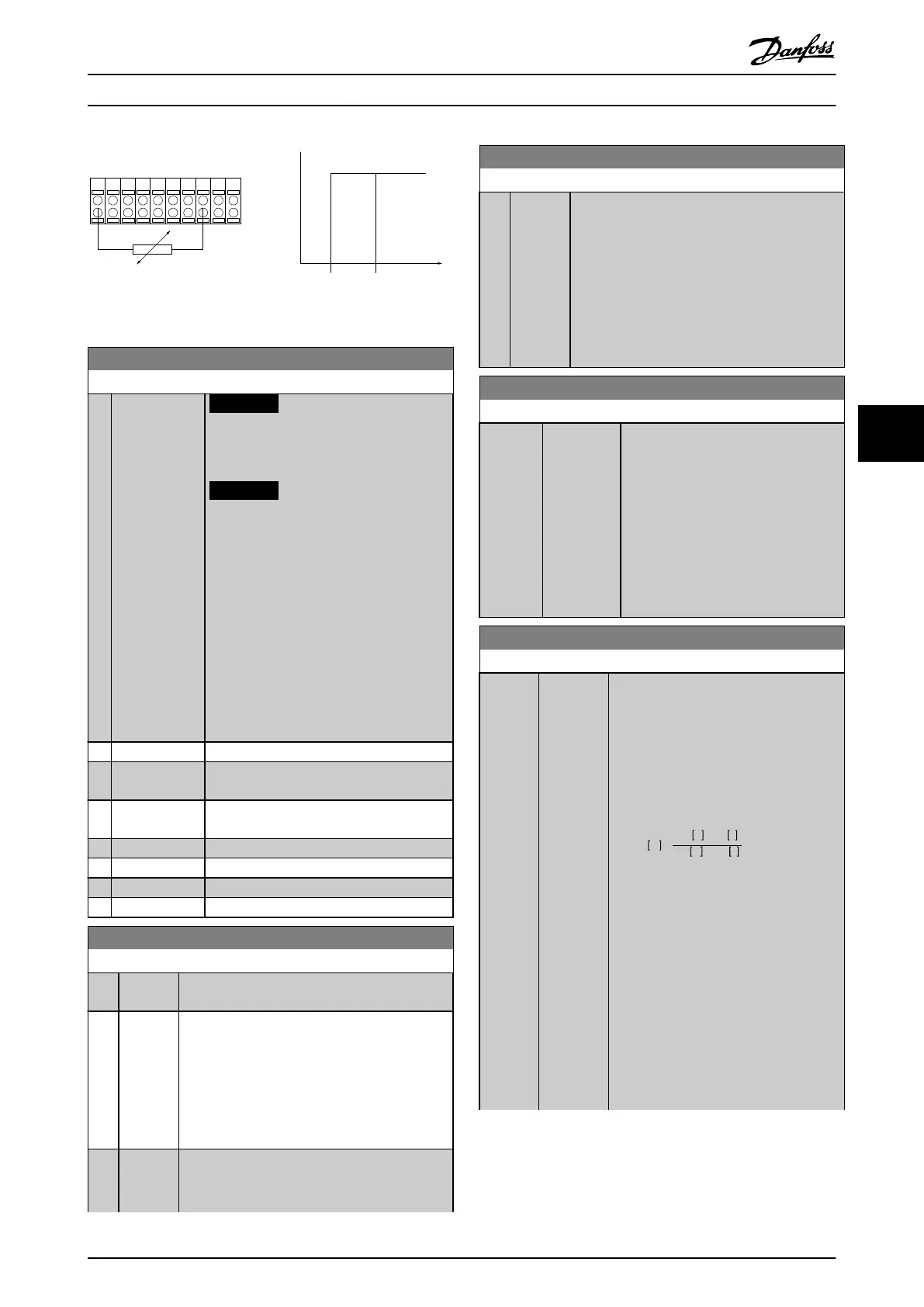

PTC / Thermistor

OFF

ON

+24V

12 13 18 3732

A

2719 29 33

B

20

GND

R<6.6 k Ω >10.8 k Ω

130BA151.11

Illustration 6.6 Klixon Example

1-93 Thermistor Source

Option: Function:

NOTICE

This parameter cannot be adjusted

while the motor is running.

NOTICE

Set digital input to [0] PNP - Active at

24 V in 5-00 Digital I/O Mode.

Select the input to which the thermistor

(PTC sensor) should be connected. An

analog input option [1] or [2] cannot be

selected if the analog input is already in use

as a reference source (selected in

3-15 Reference 1 Source, 3-16 Reference 2

Source or 3-17 Reference 3 Source).

When using MCB 112, option [0] None must

always be selected.

[0] None

[1] Analog Input

53

[2] Analog Input

54

[3] Digital input 18

[4] Digital input 19

[5] Digital input 32

[6] Digital input 33

2-10 Brake Function

Option: Function:

[0]

*

Off No brake resistor is installed.

[1] Resistor

brake

A brake resistor is incorporated in the system, for

dissipation of surplus brake energy as heat.

Connecting a brake resistor allows a higher DC

link voltage during braking (generating

operation). The Resistor brake function is only

active in frequency converters with an integral

dynamic brake.

[2] AC brake Is selected to improve braking without using a

brake resistor. This parameter controls an

overmagnetisation of the motor when running

2-10 Brake Function

Option: Function:

with a generatoric load. This function can

improve the OVC-function. Increasing the

electrical losses in the motor allows the OVC

function to increase the braking torque without

exceeding the overvoltage limit. Note that AC

brake is not as effective as dynamic braking with

a resistor.

AC brake is for VVC

plus

and flux mode in both

open and closed loop.

2-11 Brake Resistor (ohm)

Range: Function:

Size

related*

[ 5.00 -

65535.00

Ohm]

Set the brake resistor value in Ω. This

value is used for monitoring the power

to the brake resistor in 2-13 Brake

Power Monitoring. This parameter is

only active in frequency converters

with an integral dynamic brake.

Use this parameter for values without

decimals. For a selection with 2

decimals, use 30-81 Brake Resistor

(ohm).

2-12 Brake Power Limit (kW)

Range: Function:

Size

related*

[ 0.001 -

2000.000

kW]

Parameter 2-12 Brake Power Limit (kW) The

expected average power dissipated in the

brake resistor over a period of 120 s. It is

used as the monitoring limit for

16-33 Brake Energy /2 min and specifies

when a warning/alarm is issued.

To calculate 2–12 Brake Power Limit (kW),

use the following formula:

P

br,avg

W

=

U

br

2

V

×

t

br

s

R

br

Ω

×

T

br

s

P

br,avg

is the average power dissipated in

the brake resistor

R

br

is the resistance of the brake resistor.

t

br

is the active breaking time within the

120 s period, T

br

.

U

br

is the DC voltage where the brake

resistor is active, depending on the unit

as follows:

T2 units: 390 V

T4 units: 778 V

T5 units: 810 V

T6 units: 943V/1099V for D – F frames

T7 units: 1,099 V

Programming Operating Instructions

MG37A202 Danfoss A/S © Rev. 2014-07-29 All rights reserved. 55

6 6

Loading...

Loading...