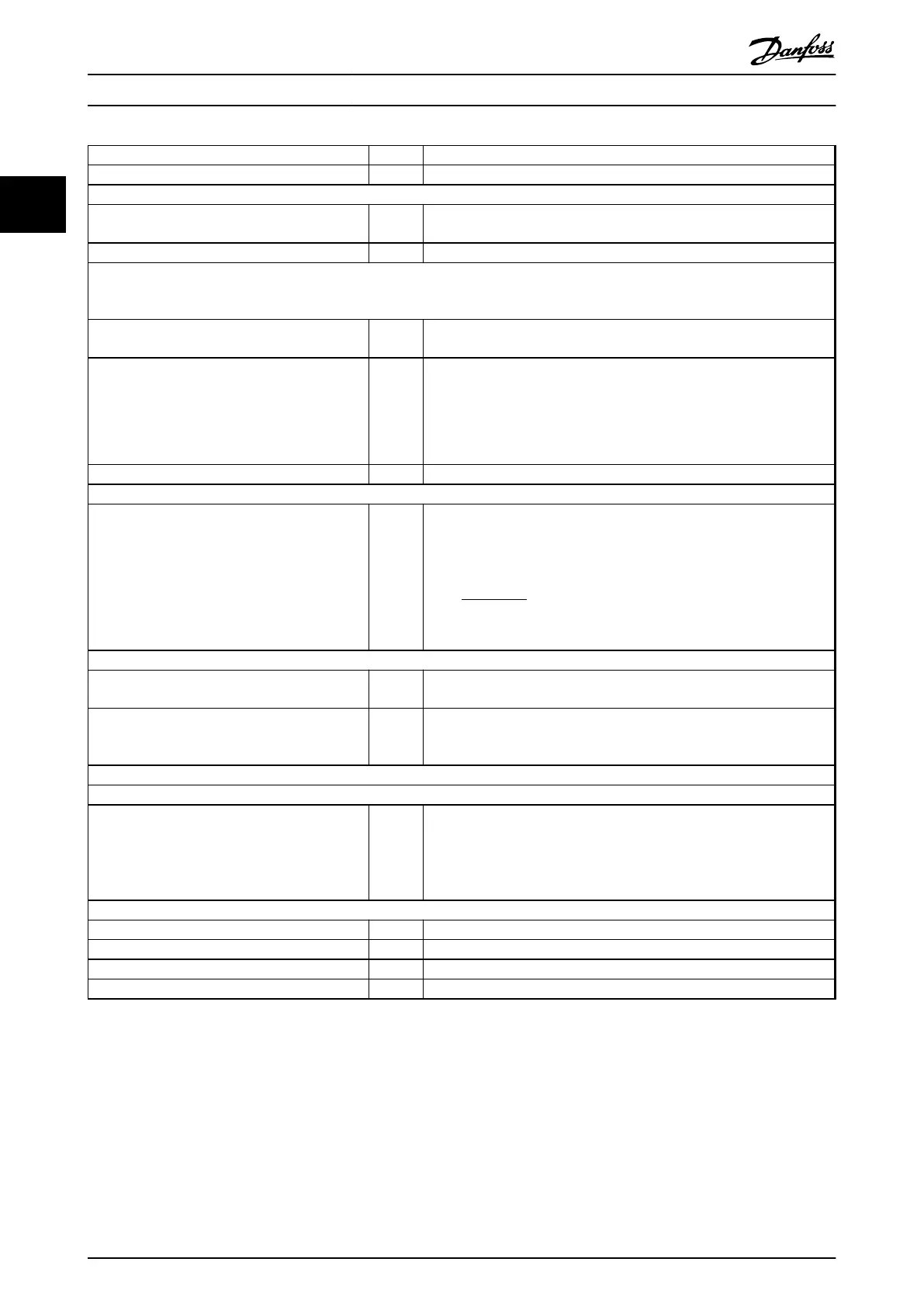

Function Par. no. Setting

Initialize the frequency converter 14-22 [2] Initialization - make a power cycling - press reset

1) Set motor parameters:

Set the motor parameters according to name plate

data

1-2* As stated on motor name plate

Perform a full Automation Motor Adaptation 1-29 [1] Enable complete AMA

2) Check that motor is running in the right direction.

When motor is connected to frequency converter with straight forward phase order as U - U; V- V; W - W motor shaft usually turns

clockwise seen into shaft end.

Press [Hand On]. Check shaft direction by applying

a manual reference.

If motor turns opposite of required direction:

1.

Change motor direction in 4-10 Motor Speed

Direction

2. Turn off mains - wait for DC link to discharge -

switch two of the motor phases

4-10 Select correct motor shaft direction

Set configuration mode 1-00 [3] Process

3) Set reference configuration, ie. the range for reference handling. Set scaling of analog input in parameter 6-xx

Set reference/feedback units

Set min. reference (10 °C)

Set max. reference (80 °C)

If set value is determined from a preset value

(array parameter), set other reference sources to

No Function

3-01

3-02

3-03

3-10

[60] ° C Unit shown on display

-5° C

35° C

[0] 35%

Ref

=

Par

. 3 − 10

(

0

)

100

×

((

Par

. 3 − 03

)

−

(

par

. 3 − 02

))

= 24, 5°

C

3-14 Preset Relative Reference to 3-18 Relative Scaling Reference Resource [0]

= No Function

4) Adjust limits for the frequency converter:

Set ramp times to an appropriate value as 20 s 3-41

3-42

20 s

20 s

Set min. speed limits

Set motor speed max. limit

Set max. output frequency

4-12

4-14

4-19

10 Hz

50 Hz

60 Hz

Set 6-19 Terminal 53 mode and 6-29 Terminal 54 mode to voltage or current mode.

5) Scale analog inputs used for reference and feedback

Set terminal 53 low voltage

Set terminal 53 high voltage

Set terminal 54 low feedback value

Set terminal 54 high feedback value

Set feedback source

6-10

6-11

6-24

6-25

7-20

0V

10V

-5° C

35° C

[2] Analog input 54

6) Basic PID settings

Process PID Normal/Inverse 7-30 [0] Normal

Process PID Anti Wind-up 7-31 [1] On

Process PID start speed 7-32 300 rpm

Save parameters to LCP 0-50 [1] All to LCP

Table 2.8 Example of Process PID Control Set-up

Product Overview

VLT

®

AutomationDrive FC 360 Design Guide

30 MG06B202 - VLT

®

is a registered Danfoss trademark

22

Loading...

Loading...