NOTE

OVC can be activated when running a PM motor (when

1-10 Motor Construction is set to [1] PM non salient SPM).

2.10 Smart Logic Controller

Smart Logic Control (SLC) is essentially a sequence of user

defined actions (see 13-52 SL Controller Action [x]) executed

by the SLC when the associated user defined event (see

13-51 SL Controller Event [x]) is evaluated as TRUE by the

SLC.

The condition for an event can be a particular status or

that the output from a Logic Rule or a Comparator

Operand becomes TRUE. That will lead to an associated

action as illustrated:

. . .

. . .

Par. 13-43

Comparator Operator

Par. 13-43

Logic Rule Operator 2

Par. 13-51

SL Controller Event

Par. 13-51

SL Controller Action

130BB671.10

Coast

Start timer

Set Do X low

Select set-up 2

. . .

Running

Warning

Torque limit

Digital inpute X 30/2

. . .

=

TRUE longer than..

. . .

. . .

Illustration 2.24 Associated Action

Events and actions are each numbered and linked together

in pairs (states). This means that when event [0] is fulfilled

(attains the value TRUE), action [0] is executed. After this,

the conditions of event [1] will be evaluated and if

evaluated TRUE, action [1] will be executed and so on.

Only one event will be evaluated at any time. If an event is

evaluated as FALSE, nothing happens (in the SLC) during

the current scan interval and no other events will be

evaluated. This means that when the SLC starts, it

evaluates event [0] (and only event [0]) each scan interval.

Only when event [0] is evaluated TRUE, will the SLC

execute action [0] and start evaluating event [1]. It is

possible to programme from 1 to 20 events and actions.

When the last

event/action has been executed, the

sequence starts over again from event [0]/action [0].

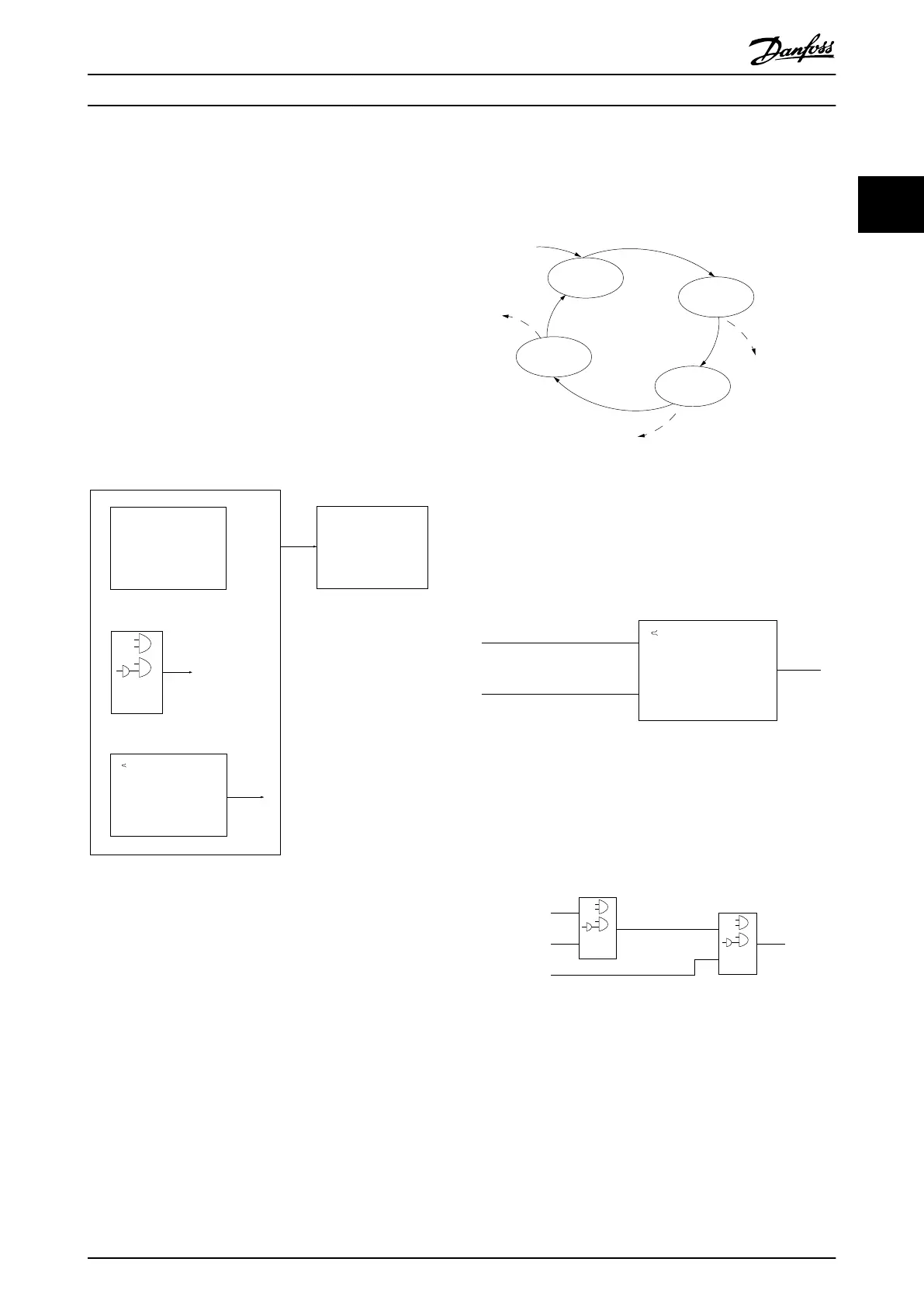

Illustration 2.25 shows an example with three event/actions:

130BA062.13

State 1

Event 1/

Action 1

State 2

Event 2/

Action 2

Start

event P13-01

State 3

Event 3/

Action 3

State 4

Event 4/

Action 4

Stop

event P13-02

Stop

event P13-02

Stop

event P13-02

Illustration 2.25 Sequence with Three Event/Actions

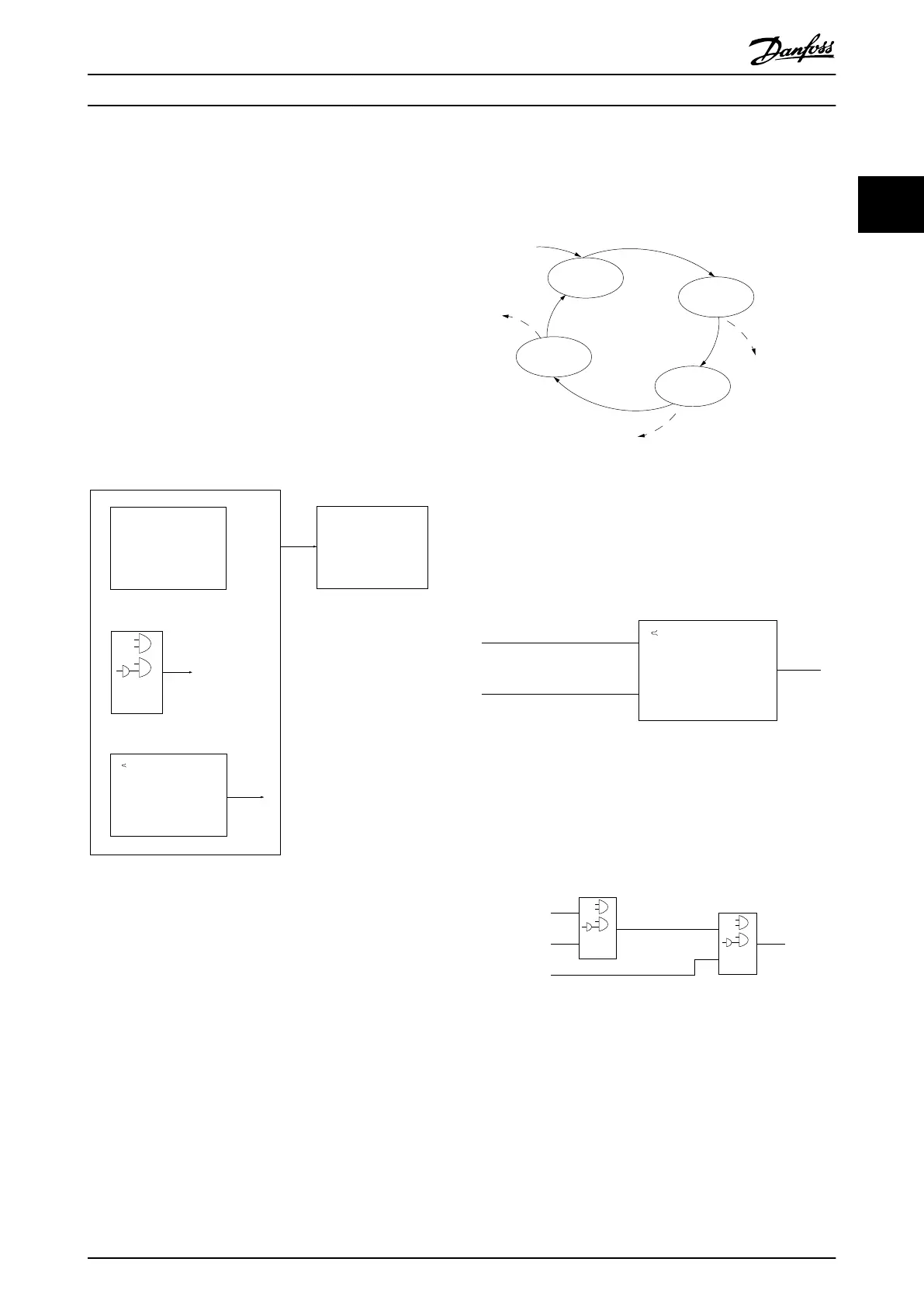

Comparators

Comparators are used for comparing continuous variables

(i.e. output frequency, output current, analog input etc.) to

fixed preset values.

Par. 13-11

Comparator Operator

=

TRUE longer than.

. . .

. . .

Par. 13-10

Comparator Operand

Par. 13-12

Comparator Value

130BB672.10

Illustration 2.26 Comparators

Logic Rules

Combine up to three boolean inputs (TRUE/FALSE inputs)

from timers, comparators, digital inputs, status bits and

events using the logical operators AND, OR, and NOT.

. . .

. . .

. . .

. . .

Par. 13-43

Logic Rule Operator 2

Par. 13-41

Logic Rule Operator 1

Par. 13-40

Logic Rule Boolean 1

Par. 13-42

Logic Rule Boolean 2

Par. 13-44

Logic Rule Boolean 3

130BB673.10

Illustration 2.27 Logic Rules

2.11 Extreme Running Conditions

Short circuit (motor phase – phase)

The frequency converter is protected against short circuits

by means of current measurement in each of the three

motor phases or in the DC link. A short circuit between

two output phases will cause an overcurrent in the

inverter. The inverter will be turned off individually when

Product Overview

VLT

®

AutomationDrive FC 360 Design Guide

MG06B202 - VLT

®

is a registered Danfoss trademark 39

2 2

Loading...

Loading...