4.1.1 Encoder Connection

The purpose of this guideline is to ease the set-up of

encoder connection to the frequency converter. Before

setting up the encoder the basic settings for a closed loop

speed control system will be shown.

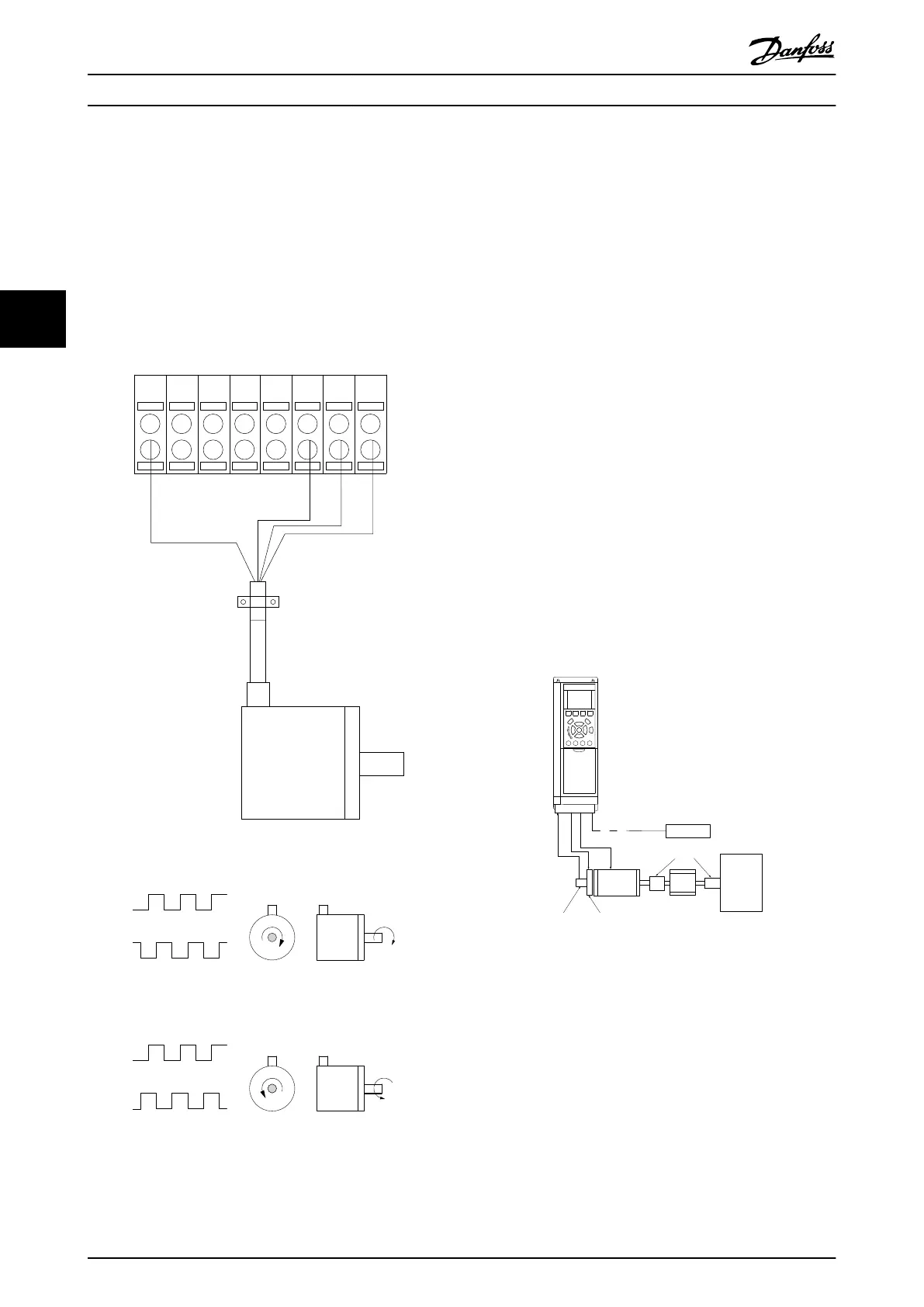

Encoder Connection to the frequency converter

130BD366.12

+24 V DC

A

B

GND

12 18 322719 29 33 20

Illustration 4.2 24 V or 10-30 V Encoder

Illustration 4.3 24 V Incremental Encoder. Max. Cable Length 5

m.

4.1.2

Encoder Direction

The direction of encoder is determined by which order the

pulses are entering the drive.

Clockwise direction means channel A is 90 electrical

degrees before channel B.

Counter Clockwise direction means channel B is 90

electrical degrees before A.

The direction determined by looking into the shaft end.

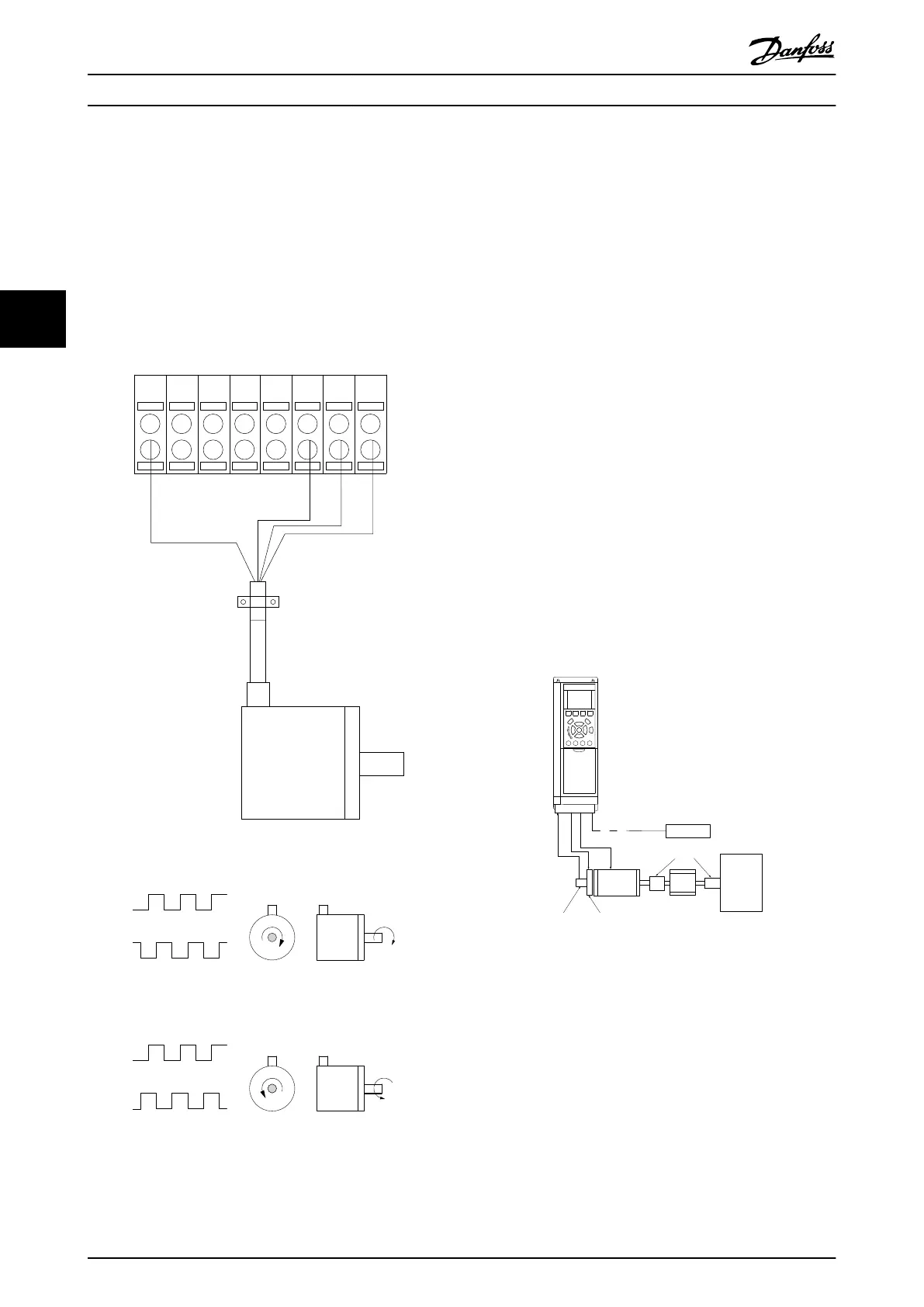

4.1.3 Closed Loop Drive System

A drive system consist usually of more elements such as:

•

Motor

•

Add

(Gearbox)

(Mechanical Brake)

•

Frequency converter

•

Encoder as feed-back system

•

Brake resistor for dynamic braking

•

Transmission

•

Load

Applications demanding mechanical brake control will

usually need a brake resistor.

Motor

Gearbox

Load

Transmission

Encoder Mech. brake

Brake resistor

130BA120.10

Illustration 4.4 Basic Set-up for Closed Loop Speed Control

Application Examples

VLT

®

AutomationDrive FC 360 Design Guide

62 MG06B202 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...