4-6

VLT is a registered Danfoss trademark

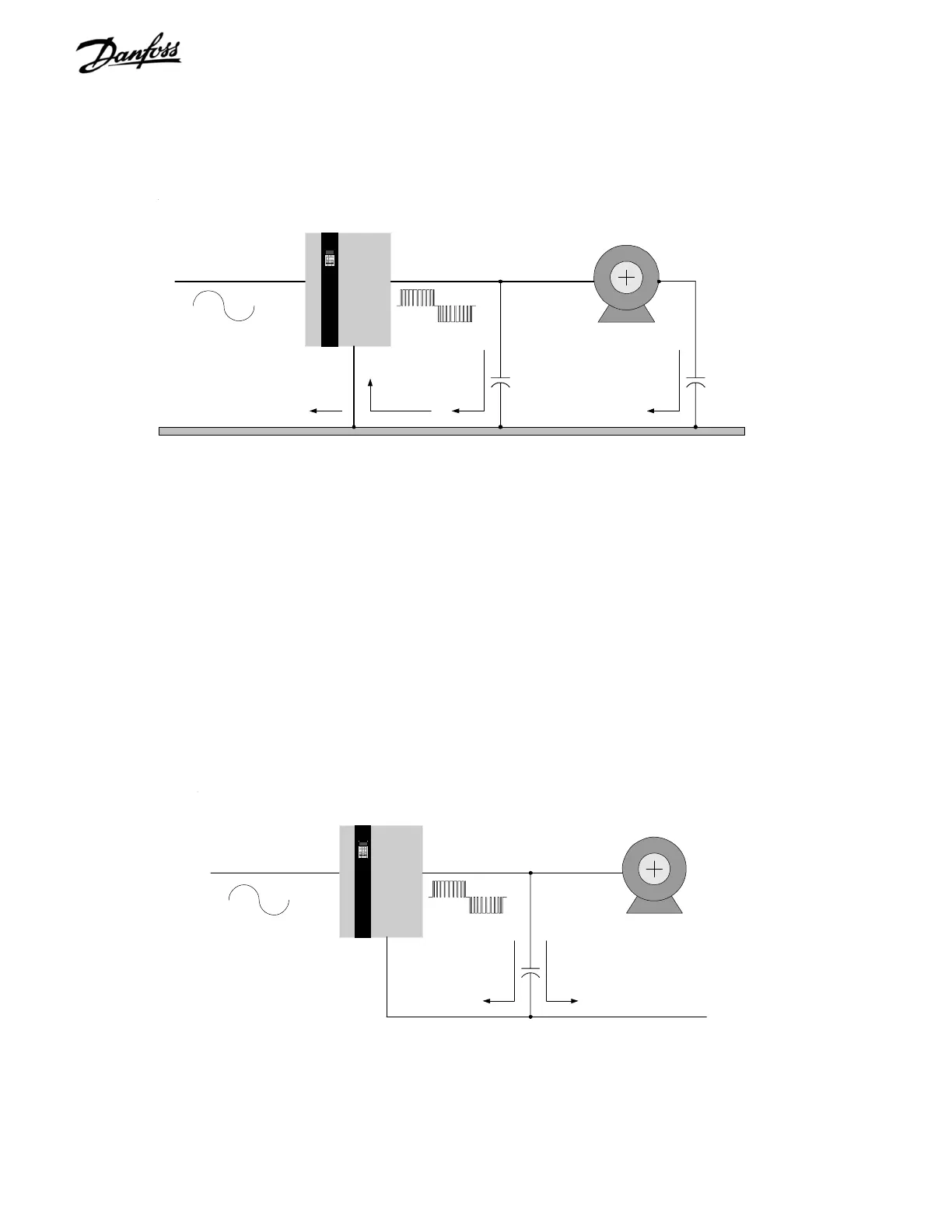

EMI Propagation

Drive generated EMI is both conducted to the AC line and

radiated to nearby conductors. See Figures 4-2 and 4-3

for illustrations.

VLT

AC Line Motor cable

Ground Potential 1 Potential 2 Potential 3

VFD

Motor

Stray capacitance Stray capacitance

Figure 4-2. Ground Currents

Stray capacitance between the motor conductors, equipment ground,

and other nearby conductors results in induced high frequency currents.

High ground circuit impedance at high frequencies results

in an instantaneous voltage at points reputed to be at

“ground potential.” This voltage can appear throughout a

system as a common mode signal that can interfere with

control signals.

Theoretically, these currents will return to the drive’s DC

bus via the ground circuit and a High Frequency (HF) bypass

network within the drive itself. However, imperfections in

the drive grounding or the equipment ground system can

cause some of the currents to travel out to the power

network.

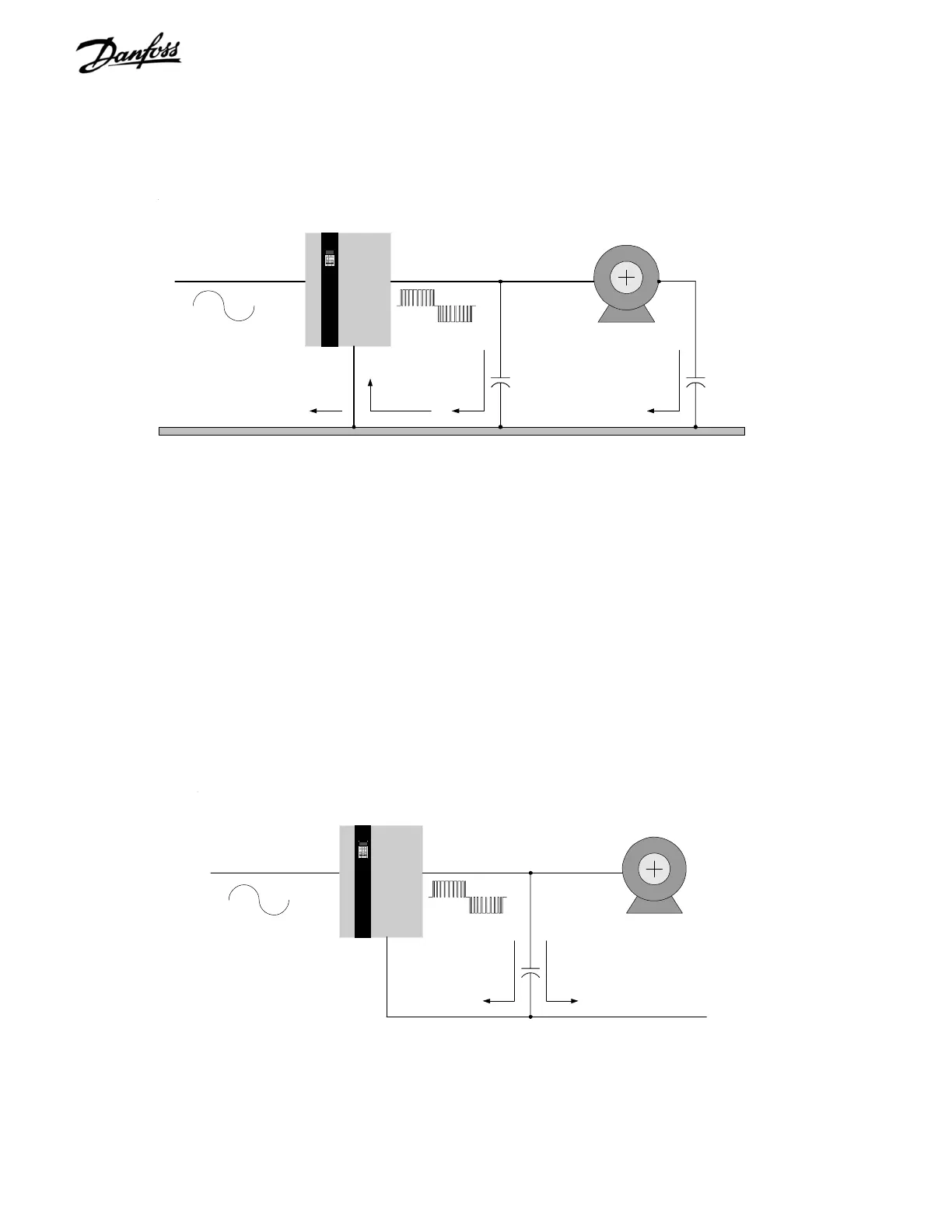

VLT

AC Line Motor cable

VFD

Motor

Stray capacitance

Signal wiring to BMS

Figure 4-3. Signal Conductor Currents

Unprotected or poorly routed signal conductors located close to or in

parallel to motor and AC line conductors are susceptible to EMI.

Loading...

Loading...