V0208, 2.42

3.2. List of I/O signals

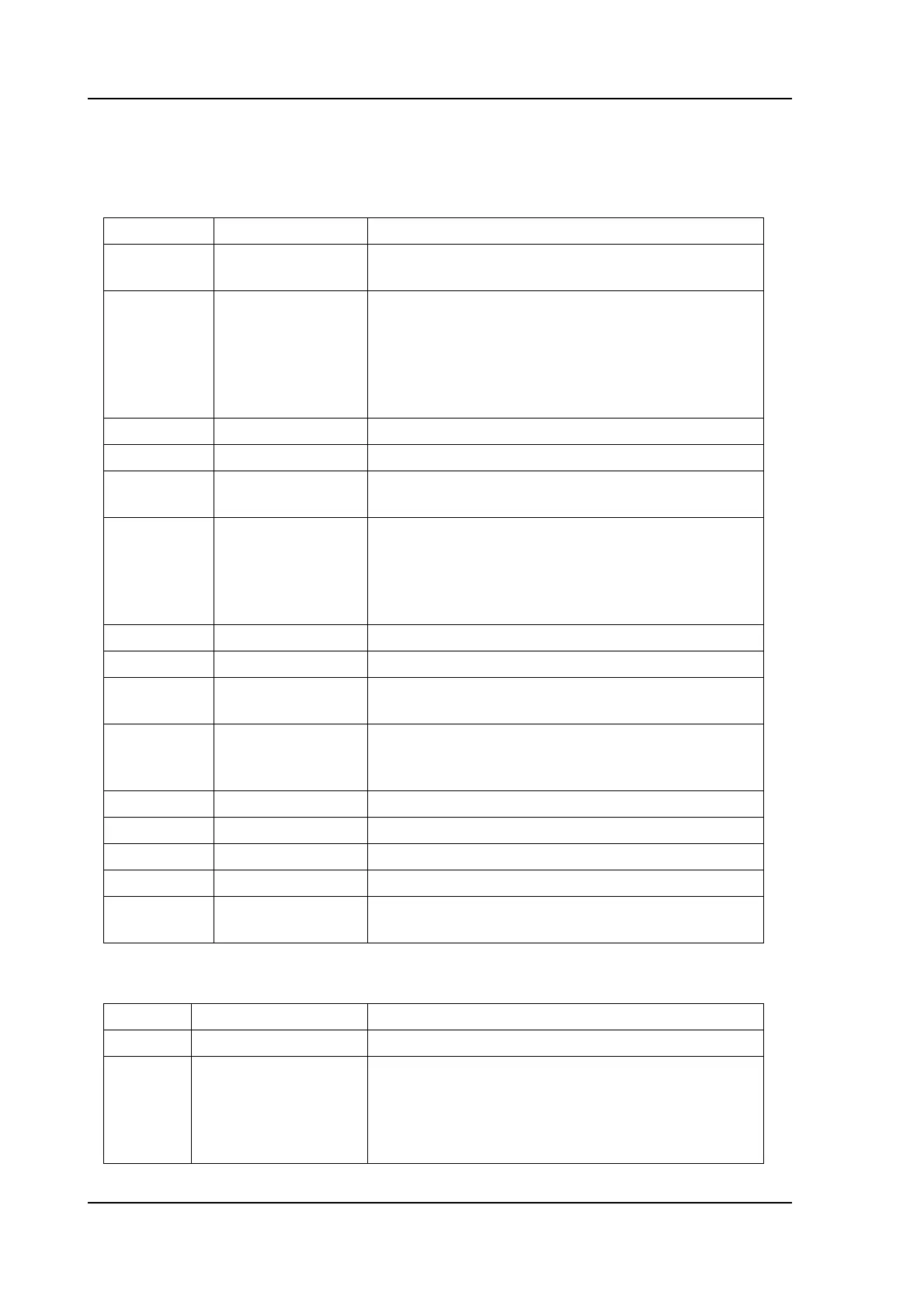

Digital input signals

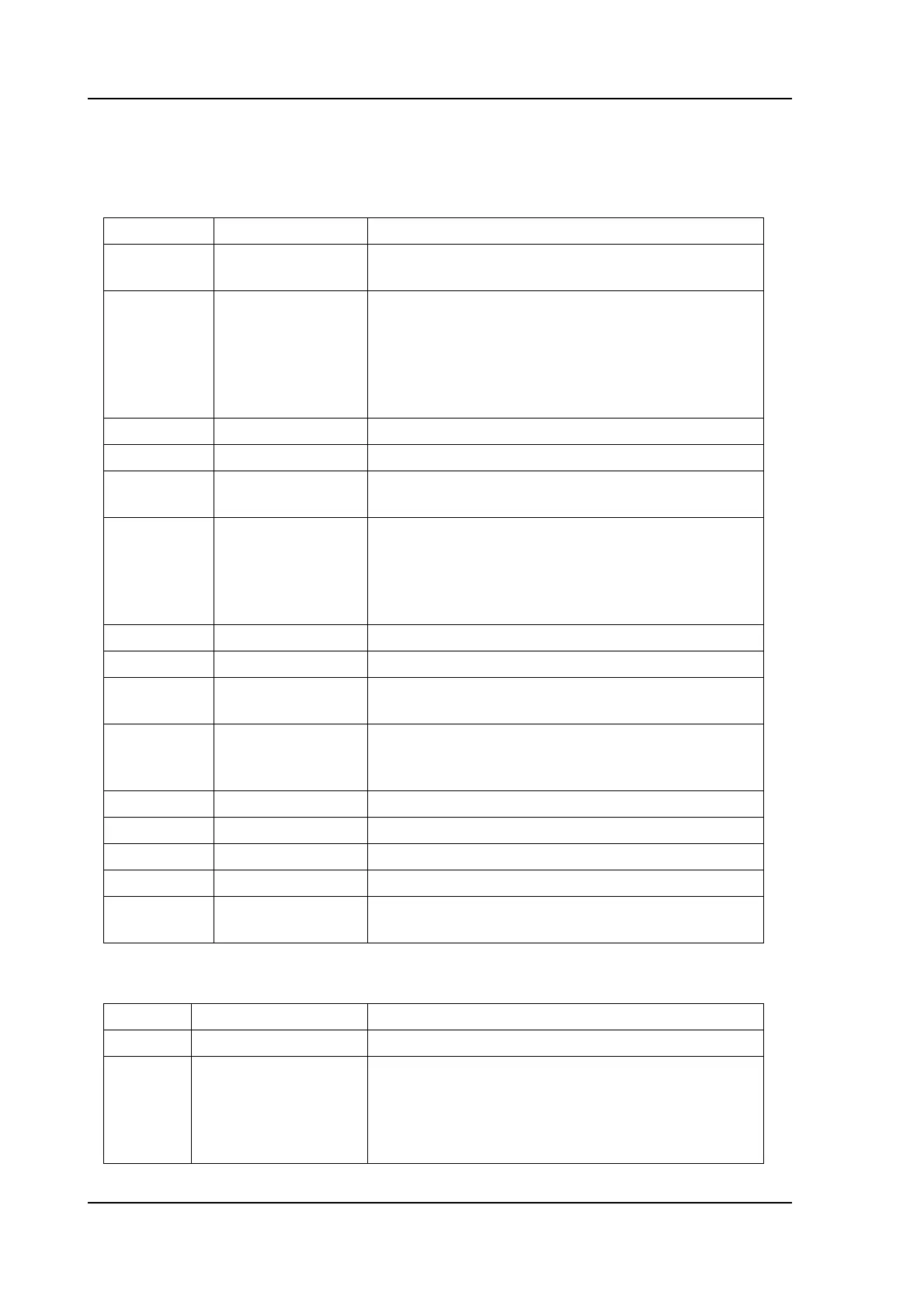

Digital output signals

Code Name Description

UDPIN UDP input Input to indicate blade is in the mechanical Upper

Dead Point.

MR Machine Ready Signal that indicates the machine is ready.

When it is low, the control cannot be started and

digital outputs and pressure outputs are disabled.

When it is high, the control can be started and the

Hours counter (parameter 91) keeps track of the

time.

ST Step input Input to change step

PEDAL Start cut Input for external signal to start cut

BR Blade Return Independent input to move the cutting blade up,

typically used for pushbutton

R Retract Retract request signal.

The Retract signal is only accepted during part of a

cutting cycle. Please see the timing diagram to

check the supported interval, as indicated by

‘RetractEnable’.

EXS External Start Input to start the control

X_RES Reset X Reset X position to 0 (support decoiling)

KEY Program enable Signal to block or enable programming on the

control.

RFC Reference

correction

Input signal for position correction. If high, the

current position value is copied from the currently

programmed position.

G2_ST Start Second gap Start input for second gap.

G1_ST Start first gap Start input for first gap.

A_ST Start Angle Start input for angle.

X_ST Start backgauge Start input for backgauge.

RSD Reference Search

Direction input

Input for reference switch for X-axis.

Code Name Description

UDP Upper Dead Point Upper Dead point has been reached.

RDY Ready Ready signal, to indicate that the control has

finished positioning. In case of a shear system, this

signal becomes high when the axis is in position

and the Gap and Angle are set correctly.

The RDY signal will remain high during retract.

Loading...

Loading...