ASDA Series Application Note Application Examples

March, 2015 3-117

Correct packing position Incorrect packing position

Figure 3.8.18 Material is misplaced

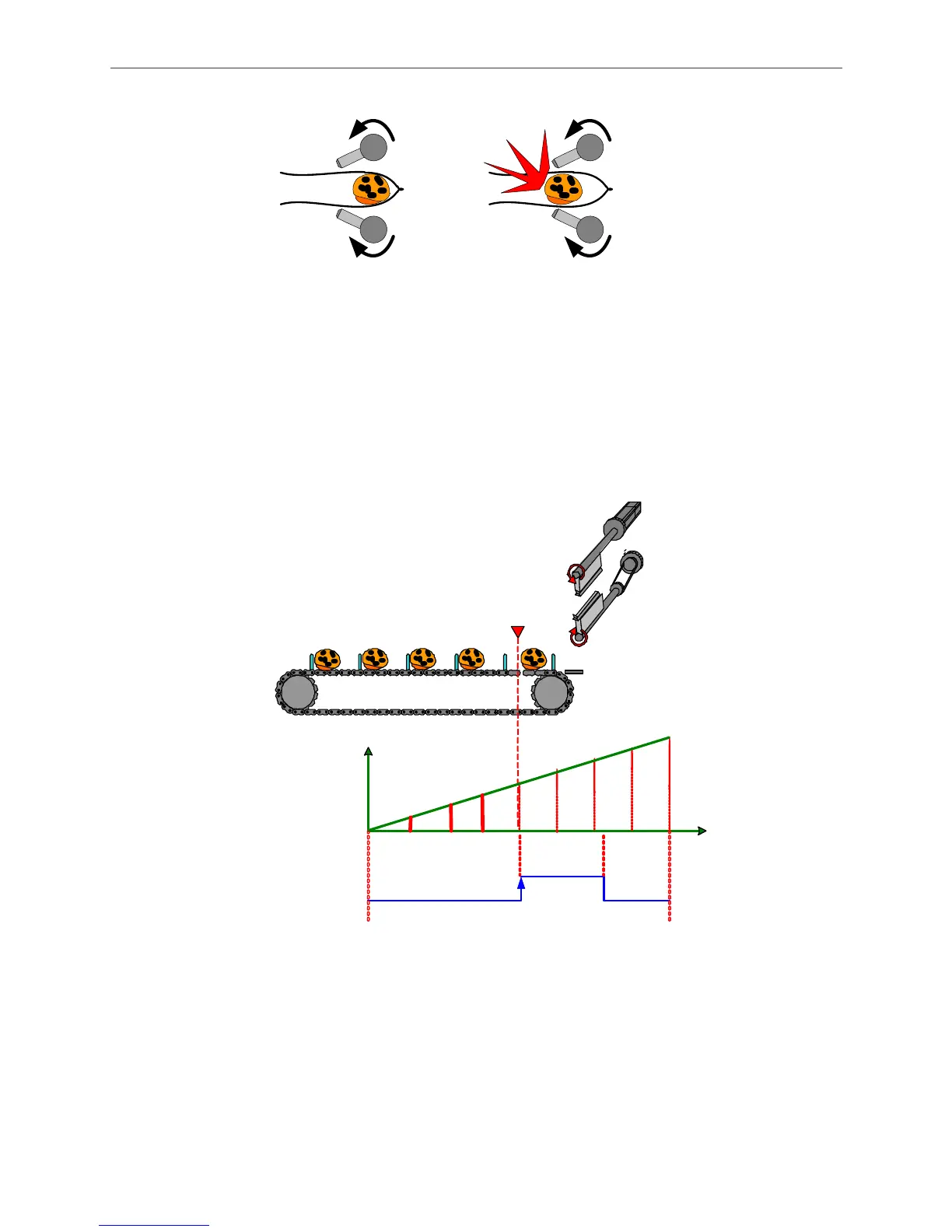

Using E-Cam output angle and the sensor could avoid and detect the material that is placed in a

wrong position. See Figure 3.8.19, when DO.0x118 is On, if the sensor does not detect the

material, it might mean the material is in a wrong position. To avoid wrong cutting, anti-cut

procedure should be activated.

Anti-cut

detection

Slave

axis

0

。

。

。

。

。

。

。

。

。

Position (PUU)

(pulse)

Master

axis

0

。

45 90 135

180

225

270

315

360

DO.0 x 118

P5-90 = 180 P5-91 = 280

。

。

。

。

。

。

。

Figure 3.8.19 Anti-cut detection

When anti-cut PR is triggered, enable macro F to calculate the moving distance between current

and target position (0 degree of the cutting curve) first. Then, use macro 8 to stop the slave axis

for a cycle and make it return to 0 degree. See Figure 3.8.20. When E-Cam is engaged, macro F

can write the correcting amount (= the position error between current and target position) into the

specified PR data.

Loading...

Loading...