ASDA Series Application Note Chapter 4 Application Techniques

March, 2015 4-33

The following macros are available from version V1.038 sub26 (included):

Command Core 000Fh Calculate the moving distance between current and target

position for PR positioning.

General Parameters N/A

Macro parameters P5-93.Low_Word = UZTX(4 digits, HEX)

YX (PR number of going trip) = 0 ~ 0X3F, it is invalid if the

value is set to 0.

UZ (PR number of return trip) = 0 ~ 0X3F, it is invalid if the

value is set to 0.

P5-93.Hi_Word = it has to be set to 0.

P5-95 (Available forward rate)= 0 ~ 100 (%)

P5-96 (target position X); Unit: pulse number of master axis

=0 ~ (P5-84/P5-83) -1.

Monitor variable 062 (3Eh): It displays the current engaged position (X) of master axis.

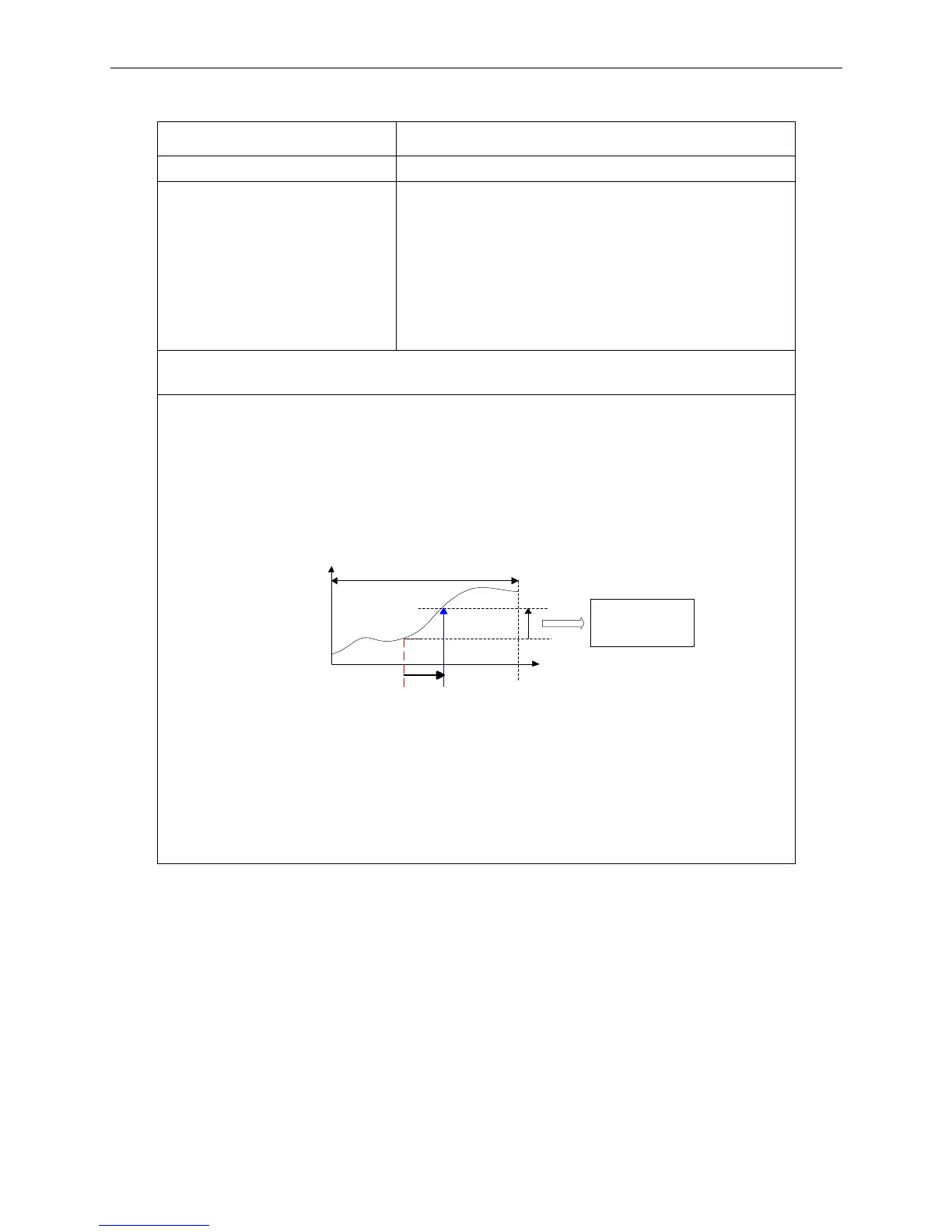

This macro command calculates the moving distance between current and target engaged

position (X) and writes into the specified PR.

During E-Cam operation, if users desire to move the slave axis to the specified position when

master axis stops and still in engaged status, this macro command can calculate the correct

moving distance (Y_Drift) of going trip for PR positioning.

When master axis resumes the operation, use another PR to run the moving distance of return

trip (-Y_Drift), it returns to the original position (moving distance of going trip + moving distance

of return trip = 0.) E-Cam position remains the same.

Pulse number of master axis after

rotating a cycle: (P5-84/P5-83) = L

Master axis position (X)

Slave axis

position (Y)

Current

engaged

position

Alignment target

position P5-96

Alignment

correction value

= Y_Diff

Note: No matter it is going trip or return trip, use incremental command when using PR.

When E-Cam moves from current position to the target one, it can rotate at forward or reverse

direction. Due to the cyclic operation, it can reach the target position either at forward or reverse

direction. However, the moving distance between both is usually different. Use available forward

rate to plan the timing of forward and reverse rotation.

*Available forward rate: The available max. proportion of forward path

Loading...

Loading...