ASDA Series Application Note Introduction of E-Cam Operation

March, 2015 2-29

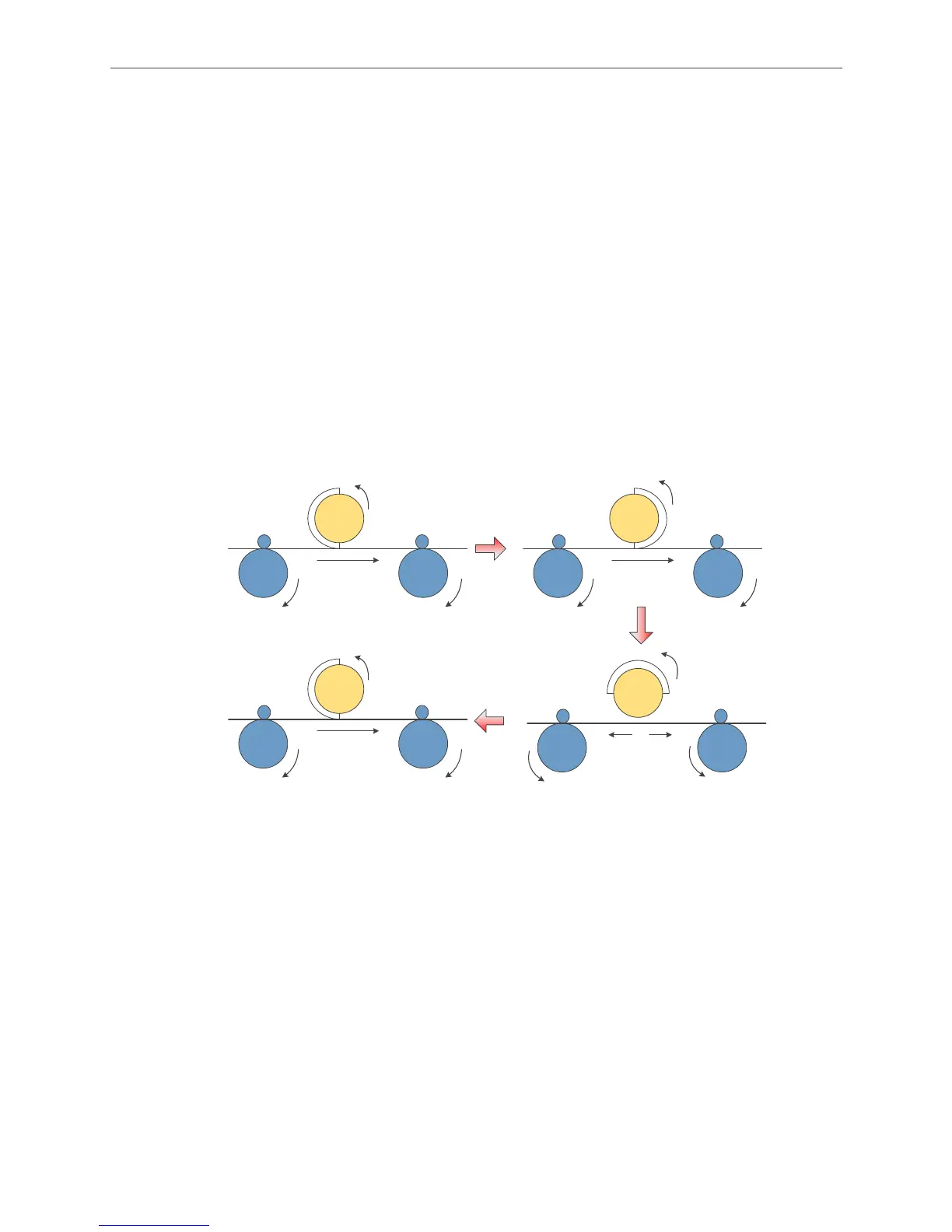

Rotary Shear- Printer Machine

Here come the operational principles:

The relation between printing axis and material feeding axis is shown in Figure 2.42. Each

printing axis does not connect to ball-screw but operates individually. Due to the printing

length limit, it cannot do full printing. The printing axis operates at constant speed and toward

the same direction. When the printing plate reaches the paper (graph A), the speed of paper

and printing plate is the same and both are in the same direction (graph B). When printing is

complete, paper and printing plate separate (graph C). Then, paper decelerates to stop and

operate towards the opposite direction for a short distance (graph D). When it starts printing

again, paper operates at the same speed and same direction as the printing cylinder. So that

the printing plate always synchronizes with the paper when printing. If the printing axis and

paper separate, paper is retrieved. Both axes still synchronize with one another. With this

pattern, the adjacent printing pattern is closely arranged with one another and it therefore

saves the use of paper. This application is very common in intermittent printing machine.

A

Printing

axis

Material

feeding

axis

Material

feeding

axis

Printing plate

The rotating direction of

printing axis

Direction of the paper

The rotating direction of

material feeding direction

Printing

axis

Material

feeding

axis

Material

feeding

axis

D

B

Printing

axis

Material

feeding

axis

Material

feeding

axis

Printing

axis

Material

feeding

axis

Material

feeding

axis

C

Figure 2.42 Motion Analysis on Intermittent Printing

See Figure 2.43. ASDA-Soft provides servo setting wizard for intermittent motion control.

Users could plan it according to the required print area and blank area and manually adjust

the angle in synchronous area and waiting area. Complete the setting of material feeding

axis by following the steps below.

Loading...

Loading...