Introduction of E-Cam Operation ASDA Series Application Note

2-30 March, 2015

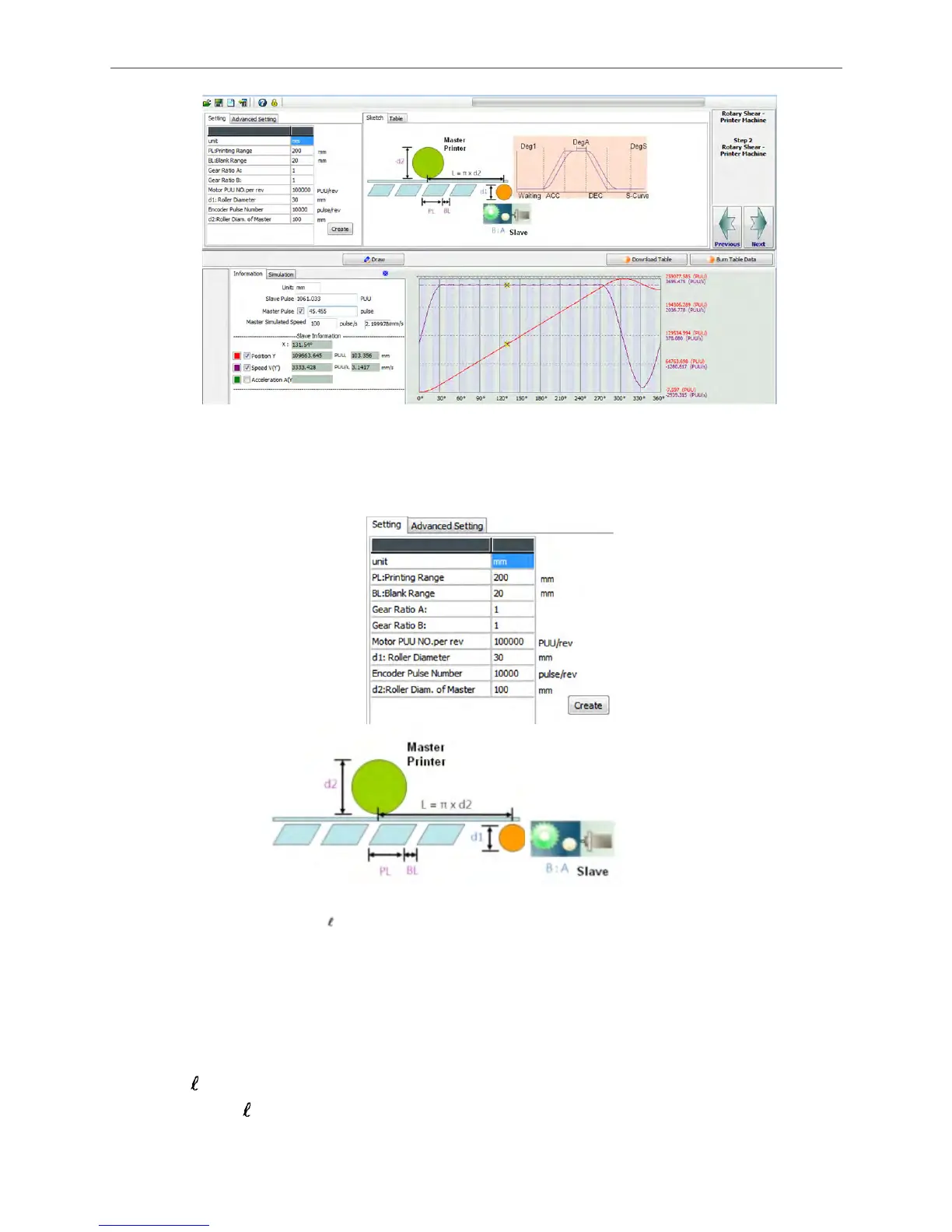

Figure 2.43 Setting Wizard for Intermittent Motion Control

When using this method to create an E-Cam curve for rotary shear printing machine,

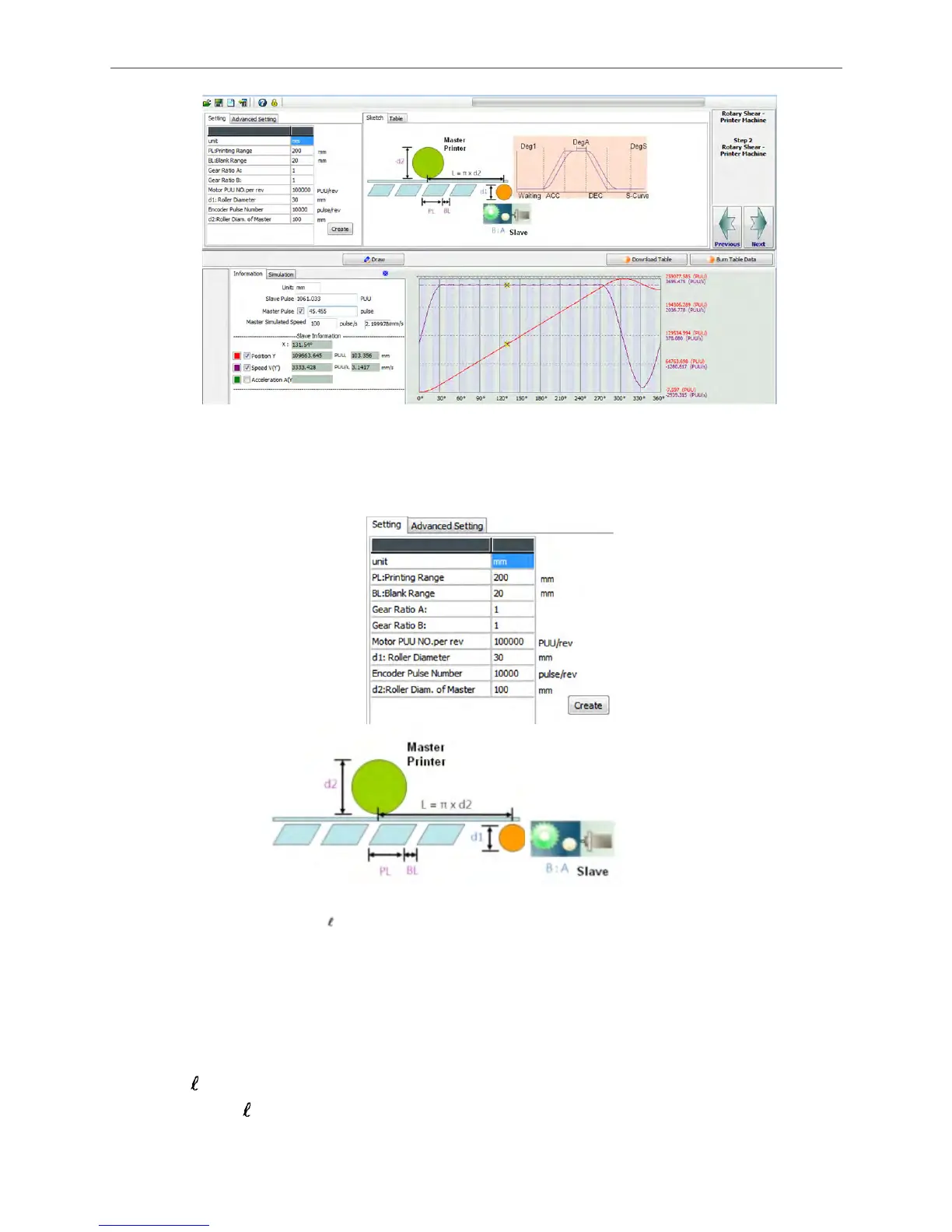

mechanical specifications have to be filled in the table. See Figure 2.44.

= PL + BL : Pitch

Printing range Blank range

Mechanical gear ratio

Propeller shaft

S-pulse

Pulse number per

revolution (PUU/rev)

Figure 2.44 Mechanical Specification Settings for Rotary Shear-Printing Machine

Users have to learn the relation of each unit of length in advance.

L (Circumference of printing cylinder) = π x d2

(Pitch of materials) = PL + BL

R = L / (equals to the “cutting length” in Rotary shear. In printing application, most cases

Loading...

Loading...