9 Electrical CAM

DVP-PM Application Manual

9-13

9.2.3.2 Start / Stop Acyclic E-CAM

In cyclic E-CAM, Master and Slave operate according to the user-defined E-CAM Data only when E-CAM

start signal (START0/PG0) is triggered. Unlike cyclic E-CAM, acyclic E-CAM operates only one cycle for

each triggered signal, i.e. E-CAM Data operates only once for one triggered signal.

Before selecting START0 as the start signal, M1035 has to be set ON for setting STOP0/START0 as the

external input. After M1035 is set OFF, M1746 = OFF will enable START0 as the start signal of acyclic

E-CAM rather than PG0.

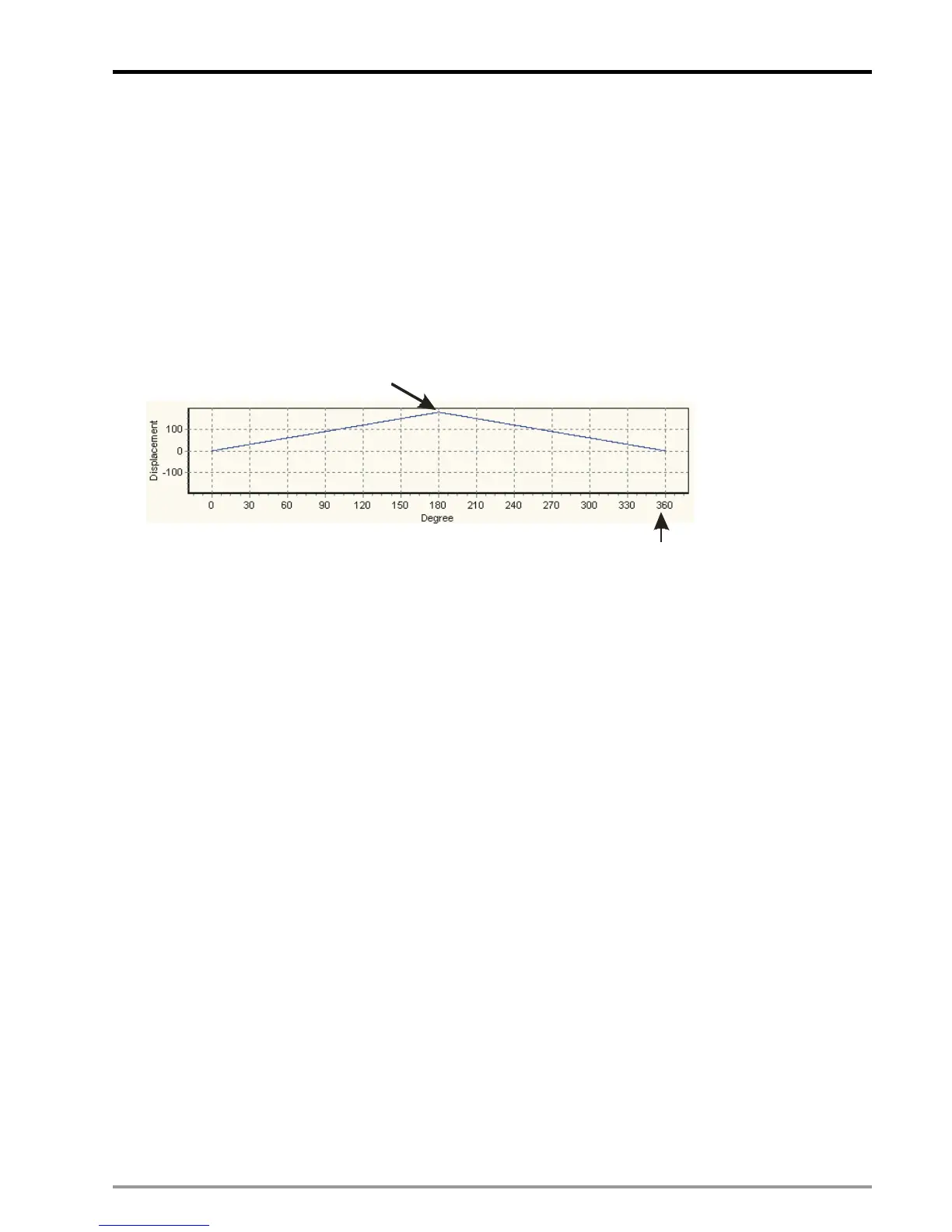

E-CAM Data

Slave

max=180

Slave unit

Master =360max

()

Master unit

Start Acyclic E-CAM

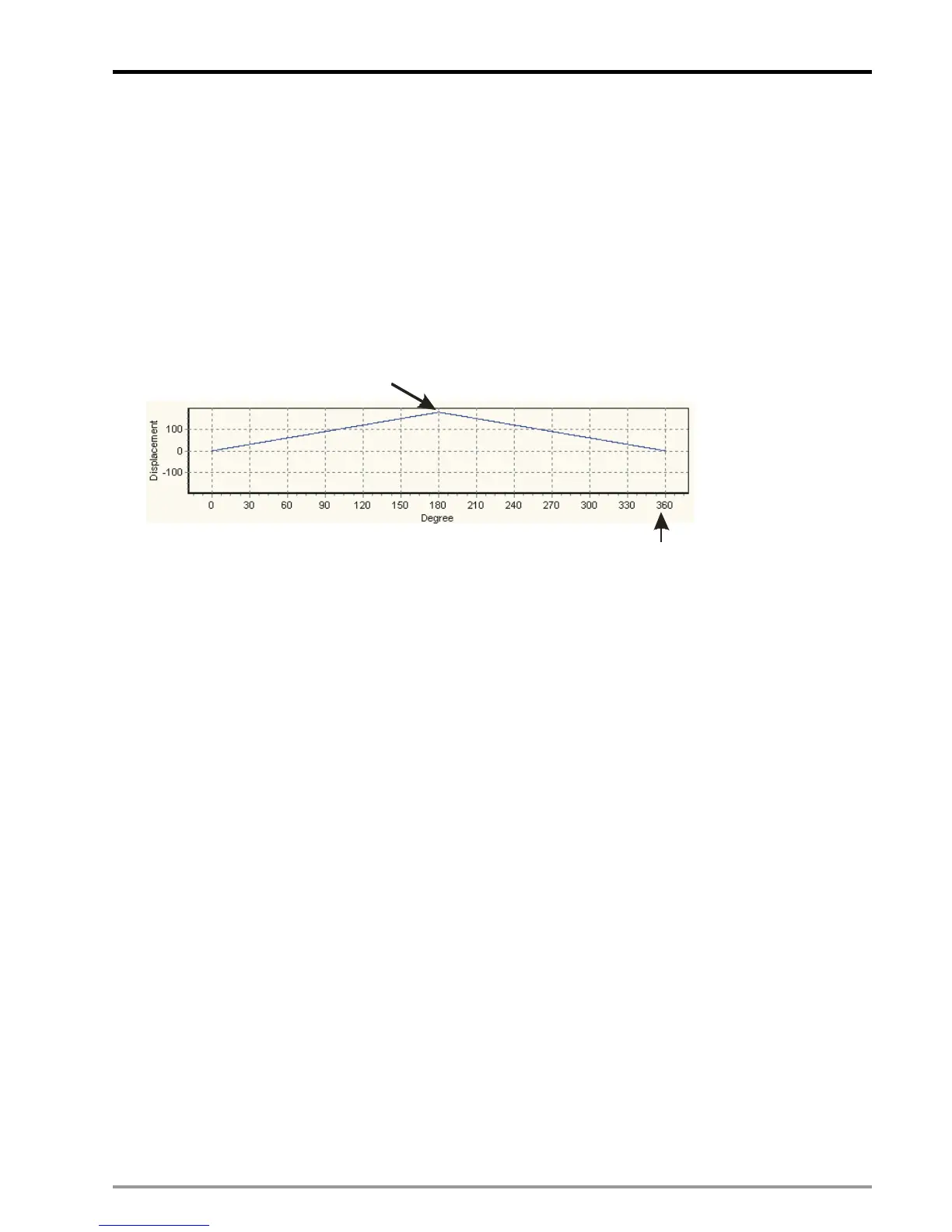

The timing diagram below indicates an operation process of acyclic E-CAM operation with synchronized

output position between 60~300.

1. In T1, D1846 bit 14 = ON, acyclic E-CAM is enabled

2. After the initialization interval of T2, M1812 = ON to indicate the completion of E-CAM initialization. At

this time Slave is still not activated.

3. In T3, acyclic operation starts after START0/PG0 (Input terminal for enabling acyclic E-CAM) is ON.

When M1746 = ON, PG0 is the start signal of acyclic E-CAM; when M1746 = OFF and M1035 = ON,

START0 is the start signal of acyclic E-CAM. In this case Slave starts to operate a cycle according to

the E-CAM Data. (“M1035 = ON” enables START0 / STOP0 as the external input point).

4. When the cycle is completed at T4, DVP-PM will clear the state of M1812 = ON. In addition, users can

also confirm the E-CAM completion by ON state of M1813.

5. In T5, you can decide whether to set ON M1812 for confirming the next E-CAM completion.

6. In T6 and T7, actions of T3~T4 will be repeated. Please note that the interval for enabling acyclic

E-CAM should be longer than 5ms.

7. CLR0 outputs according to the upper/lower bound of sync output during each E-CAM cycle.

Loading...

Loading...