9 Electrical CAM

DVP-PM Application Manual

9-41

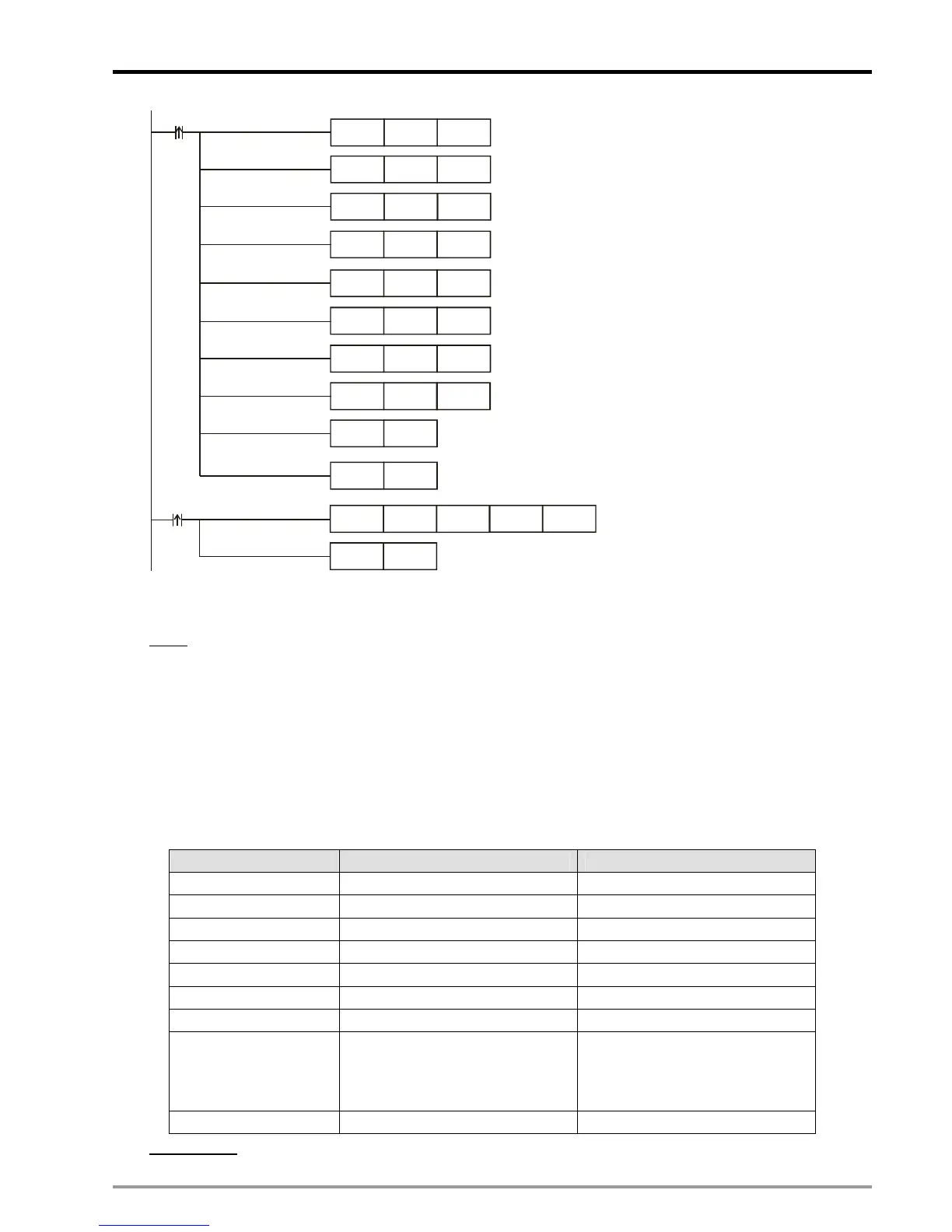

DFLT K1 D106

M1

DMOV K1000 D100

M0

SET

M1035

DFLT K10

D108

DTO K100 D0

DMOV K10000 D0

DMOV K500 D102

DMOV K200 D104

RST M0

MOV

K0

D110

D100

MOV H4000

D111

RST

D112

K7

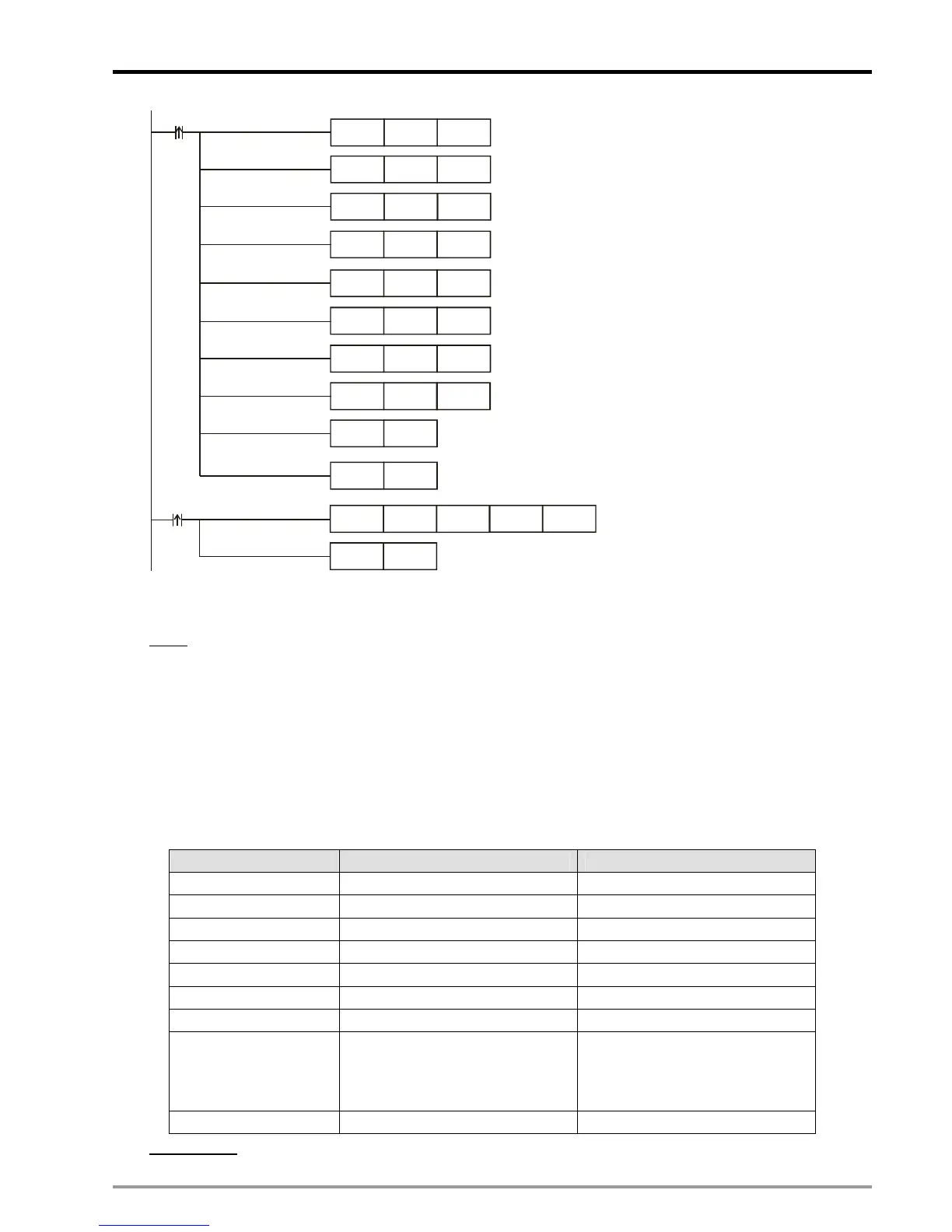

Application Example 2: Flying Saw Application

Setup

:

Flying saw operation can be performed by applying 2 rotary cut E-CAM curves. First, we need to create the

1

st

E-CAM curve for rotay cut. Second, design the 2

nd

E-CAM curve, in which length of Slave is specified with

a negative value of the previous E-CAM curve. In addition, set up the 6

th

data (D111 in this example) to

borrow the previous E-CAM data setting and combine the 2 E-CAM curves, so that a reciprovating flying saw

operation can be performed.

To create the above flying saw CAM curve, 2 blank E-CAM data spaces of resolution 300 (Total 600 points)

should be created before running the program. The set values of the 2 E-CAM are as below.

Parameters SV of 1

st

rotary cut E-CAM SV of 2

nd

rotary cut E-CAM

Length of Master 1000 1000

Length of Slave 500

-500

Length of sync area 200 200

Magnification ratio 1.0 1.0

Max magnification ratio 10.0 10.0

Acceleration curve 0 0

CAM curve 0 0

CAM curve setting

Only single data real-time

modification is applicable

1. Only single data real-time

modification is applicable

2. Borrow the previous E-CAM

data setting

Results 0 0

Control Steps:

Loading...

Loading...