9 Electrical CAM

DVP-PM Application Manual

9-43

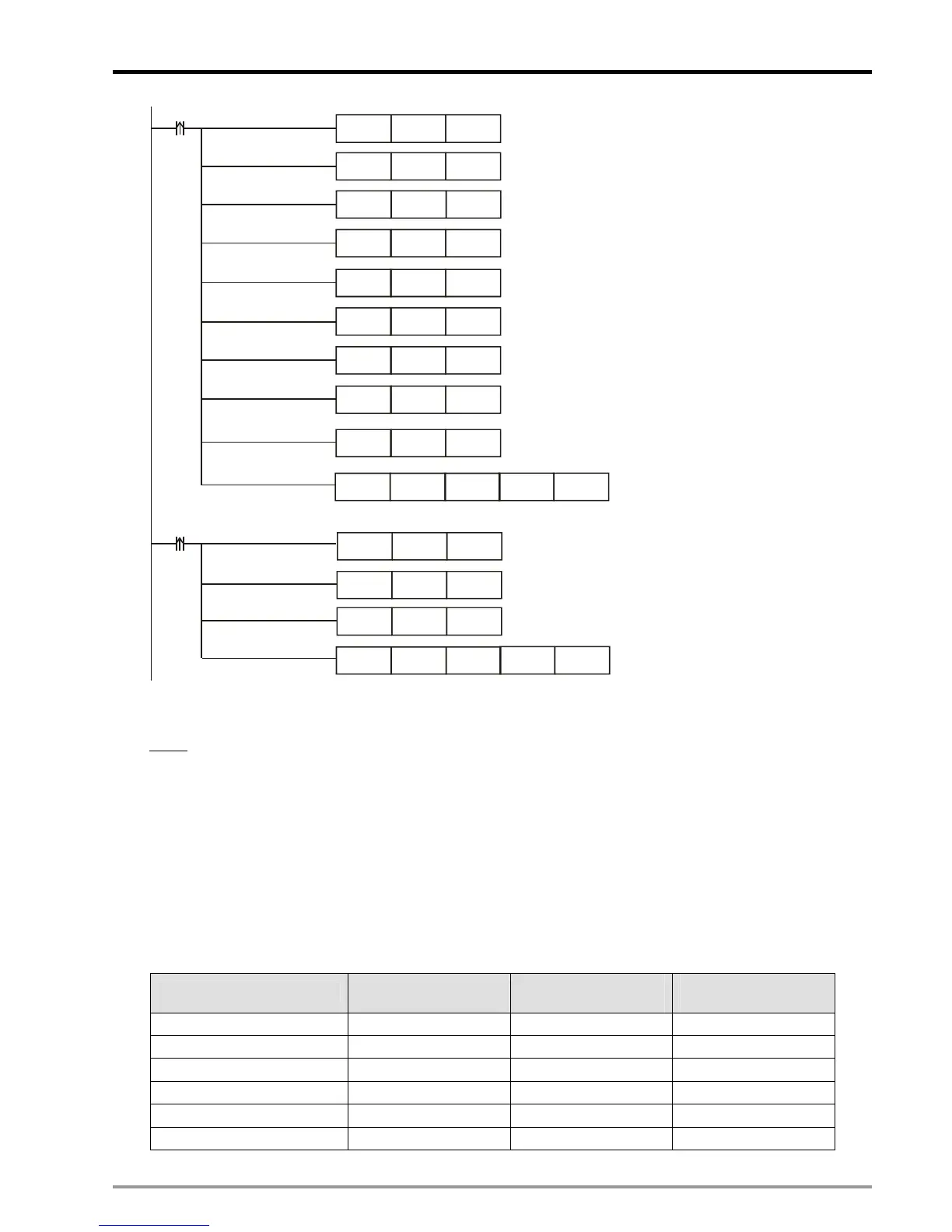

DFLT K1 D106

M0

DMOV K1000 D100

DFLT

K10

D108

DMOV K10000 D0

DMOV K500 D102

DMOV K200 D104

MOV

K0

D110

MOV

H4000

D111

DTO K100 D0 D100 K7

M1

DMOV K-500 D102

DMOV K200 D104

MOV

HC000

D111

DTO K100 D0 D100 K7

MOV

K0

D112

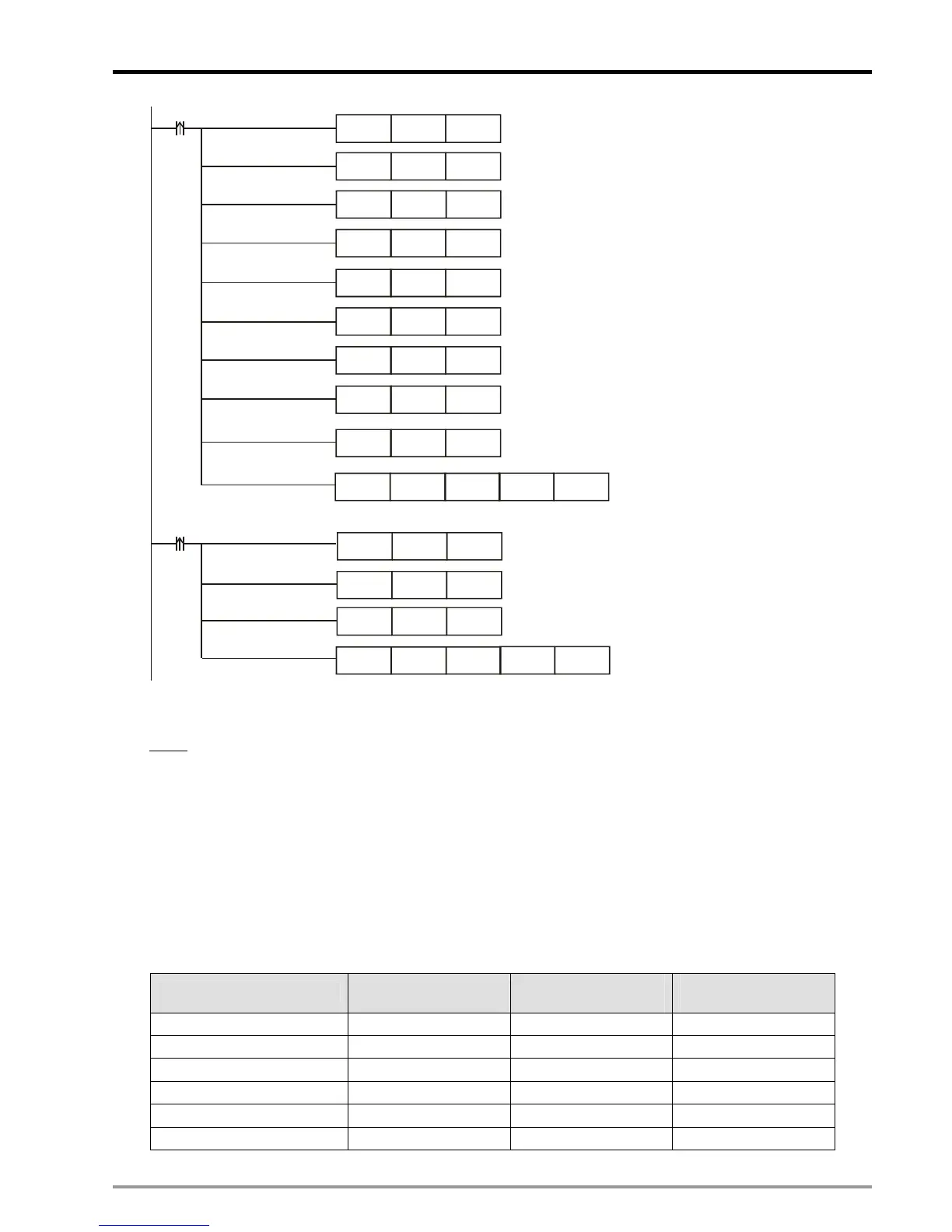

Application Example 3: Multi-cutter application

Setup

:

In multi-cutter application, such as rotary cut with 3 cutters, the pulses per round of Slave can not be evenly

distributed to each cutter and the error of Slave will increase as the execution times increase. In this case,

the CAM data of each cutter should be designed respectively and the sum of the data length of 3 cutters

should equal to total pulses per round.

To meet this requirement, we only need to design the data setting of the first E-CAM once and set up the

associated register for borrowing the data setting from the previous E-CAM curve. By this function, the 3

CAM curves can be well connected and the pulses per round of Slave can be fulfilled. The set values of the

3 E-CAM are as below.

Parameters

SV of 1

st

rotary cut

E-CAM

SV of 2

nd

rotary cut

E-CAM

SV of 3

rd

rotary cut

E-CAM

Length of Master 1000 1000 1000

Length of Slave 333 333

334

Length of sync area 200 200 200

Magnification ratio 1.0 1.0 1.0

Max magnification ratio 10.0 10.0 10.0

Acceleration curve 0 0 0

Loading...

Loading...