2

360

-

360

÷

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

⋅×

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

=

roundperPulses

cuttersofNumber

roundperPulses

roundperPulses

αθ

α

θ

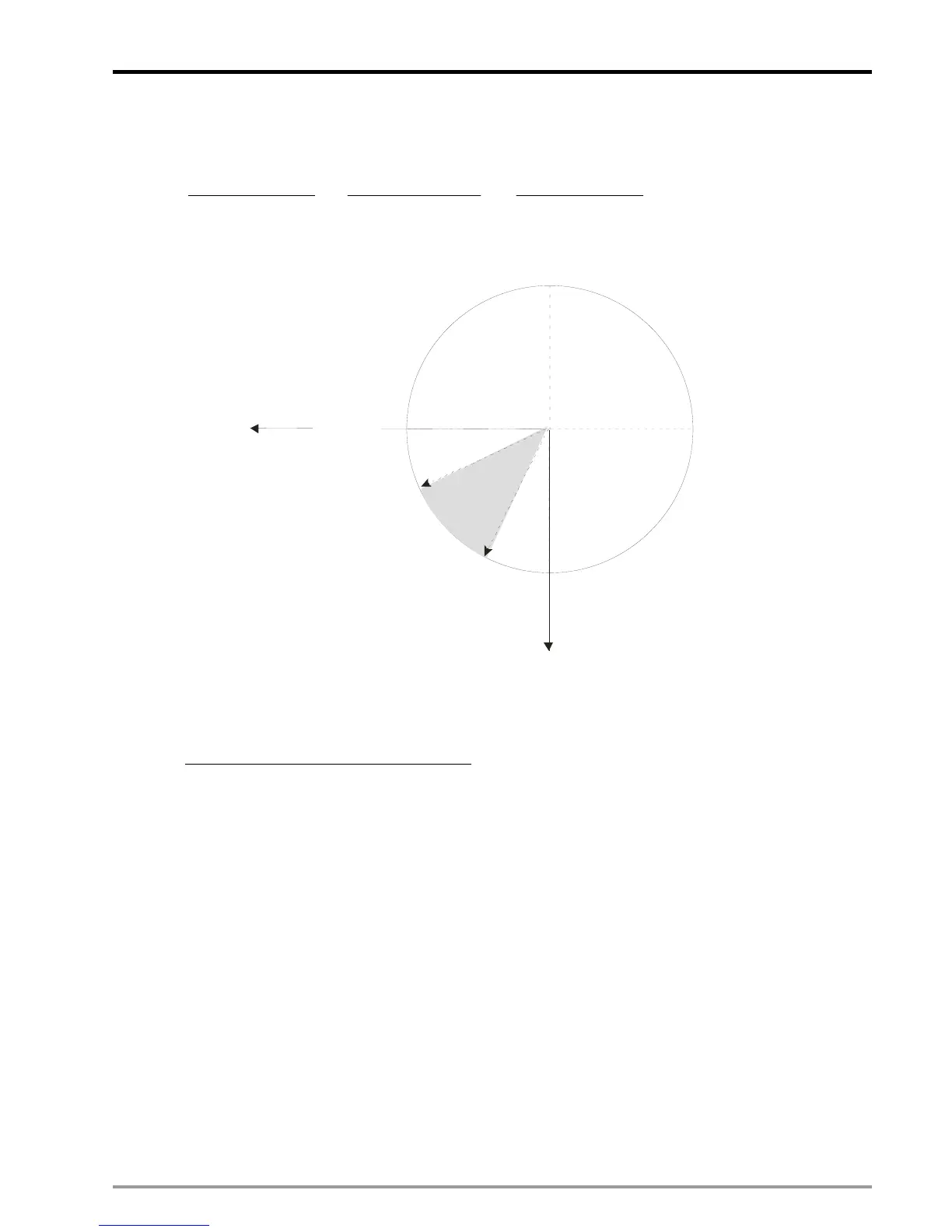

θ

180

90

0 or 360

270

Sync start angle

Sync end angle

End position of the cutter

Start position

of the cutter

The actual adjustment steps are: 1. select the sync start and sync end angle; 2. align the cutter with the start

position of the cutter; 3. Execute E-CAM operation; 4. Inspect the cutting plane on material. If the cutting

plane is bended, conduct fine tuning on the sync start/end angle until the cutting plane is flat and smooth.

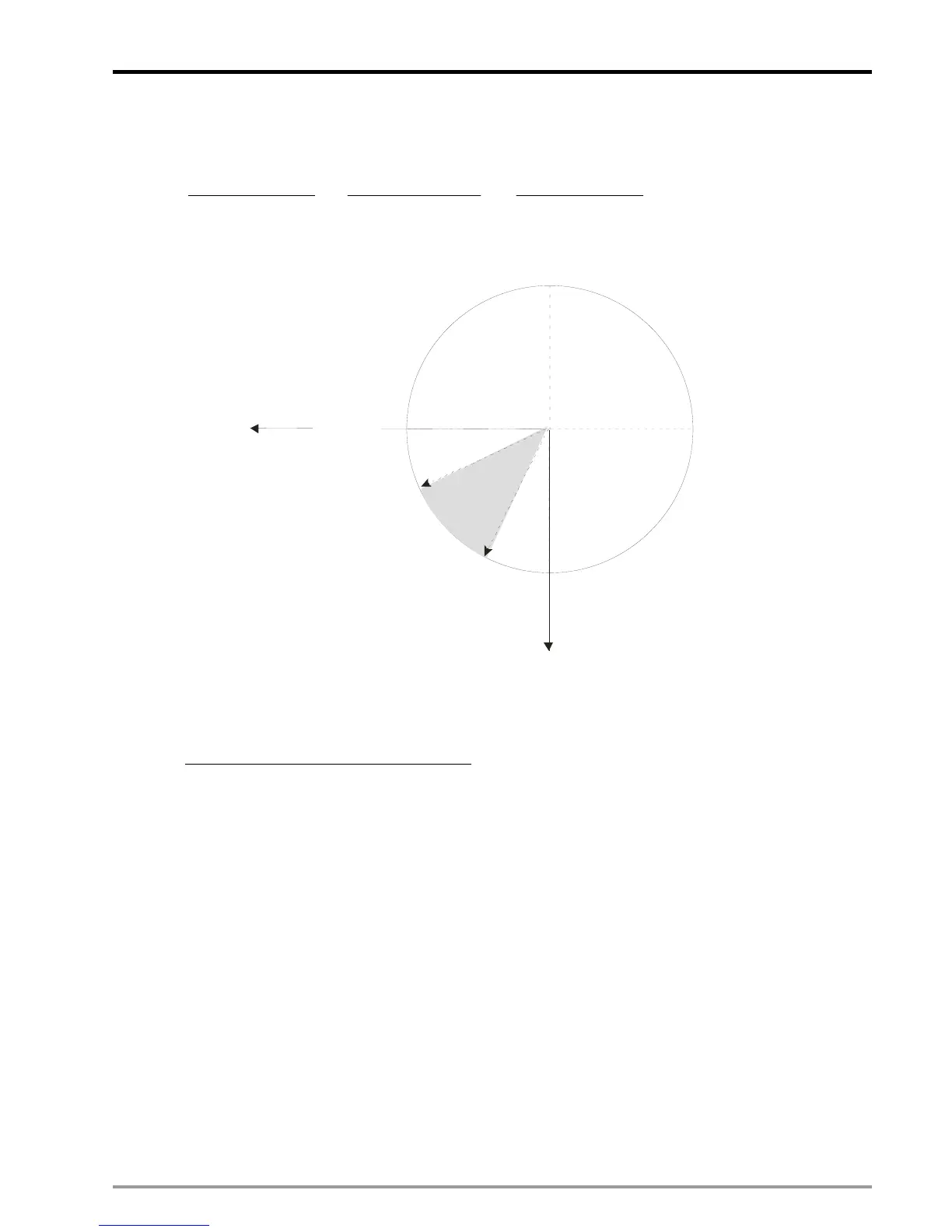

z Case 2: Pulses can NOT be equally divided:

If the total pulses of Slave can not be equally divided by the cutters, angle θ

1

and the length of Master

before sync area should be specified respectively in E-CAM setting, so that the starting and end position of

each cutter can be obtained. As the diagram below, parameters including angle θ

1

, length of Master before

sync area, sync start angle and sync end angle should be specified respectively. In addition, the pulses

required for each cutter should also be specified in E-CAM setting. When the above parameters are ready,

run the thick material cutting E-CAM and conduct fine-tuning on the parameters of each cutter until the best

results are obtained.

Loading...

Loading...