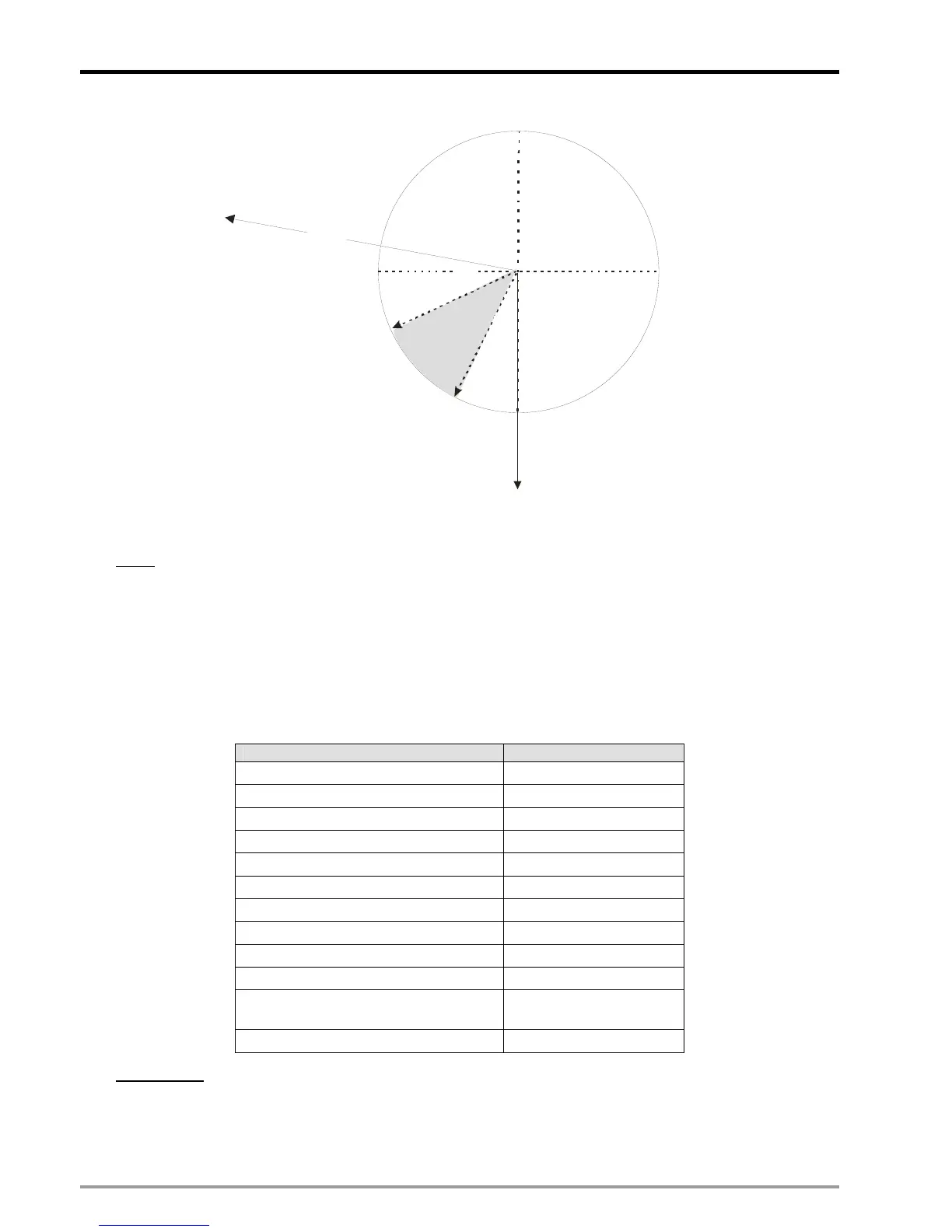

0 or 360

270

Sync start angle

Sync end angle

End position of cutter

Start position of cutter

θ1

θ2

Application Example:

Setup

:

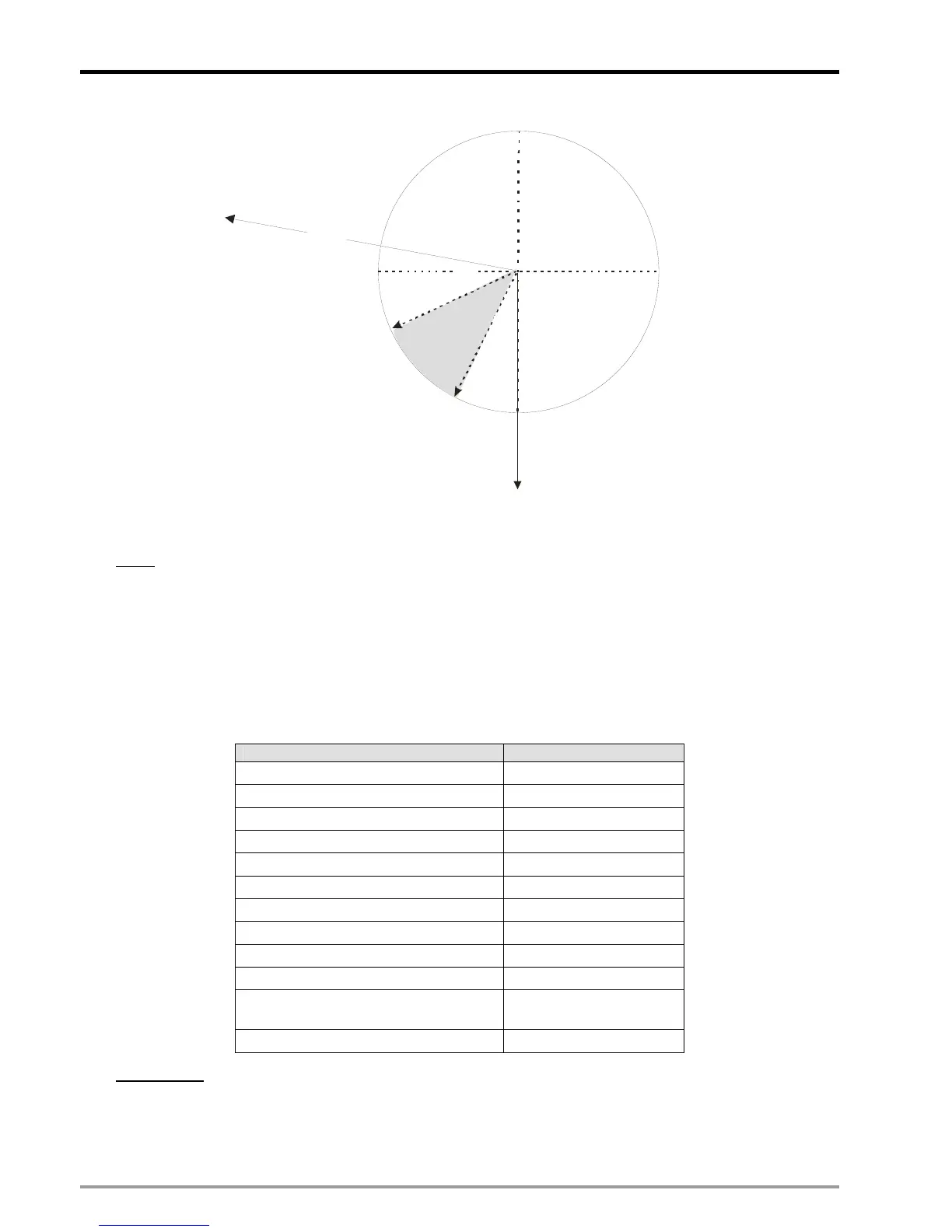

The example is the application of using DTO instruction for creating thick matrrial cutting E-CAM. The

required parameters are listed in the table below. We assume that the diameter of material feeding axis is

170(mm), diameter of cutting axis is 240(mm), number of cutters: 4, pulses per round: 200,000, sync start

angle of Slave: θ

1 = 210 degree, and sync end angle of Slave: θ2 = 250 degree. The cutting length can be

calculated according to the parameters above: 170×314÷4=13345. Parameters for thick-material cutting are

listed as below.

Data Set value

E-CAM format 1

Pulses per round of Master 200000

Length per round of Master 53380

Pulses per round of Slave 200000

Length per round of Slave 75360

Sync start angle of Slave:180~360 210

Sync end angle of Slave:180~360 250

Length of cutting process on Master 13345

Number of cutters on Slave 4

Length of Master before sync area -

Angle of Slave between start position

and sync start: angle θ

1

(degree)

-

Number of data points in sync area -

Control Steps:

Step 1: Add 2 sets of E-CAM charts and set the resolution as 407.

Step 2: Download the below program in DVP-20PM and execute.

Loading...

Loading...