4.1.2. Sampling needle setting

This adjustment sets the sampling needle to the operational position.

In Service menu, in Miscellaneous submenu of HM5 select Needle setting.

The software moves the needle back and up, and turns on horizontal and vertical motors to

keep needle in place.

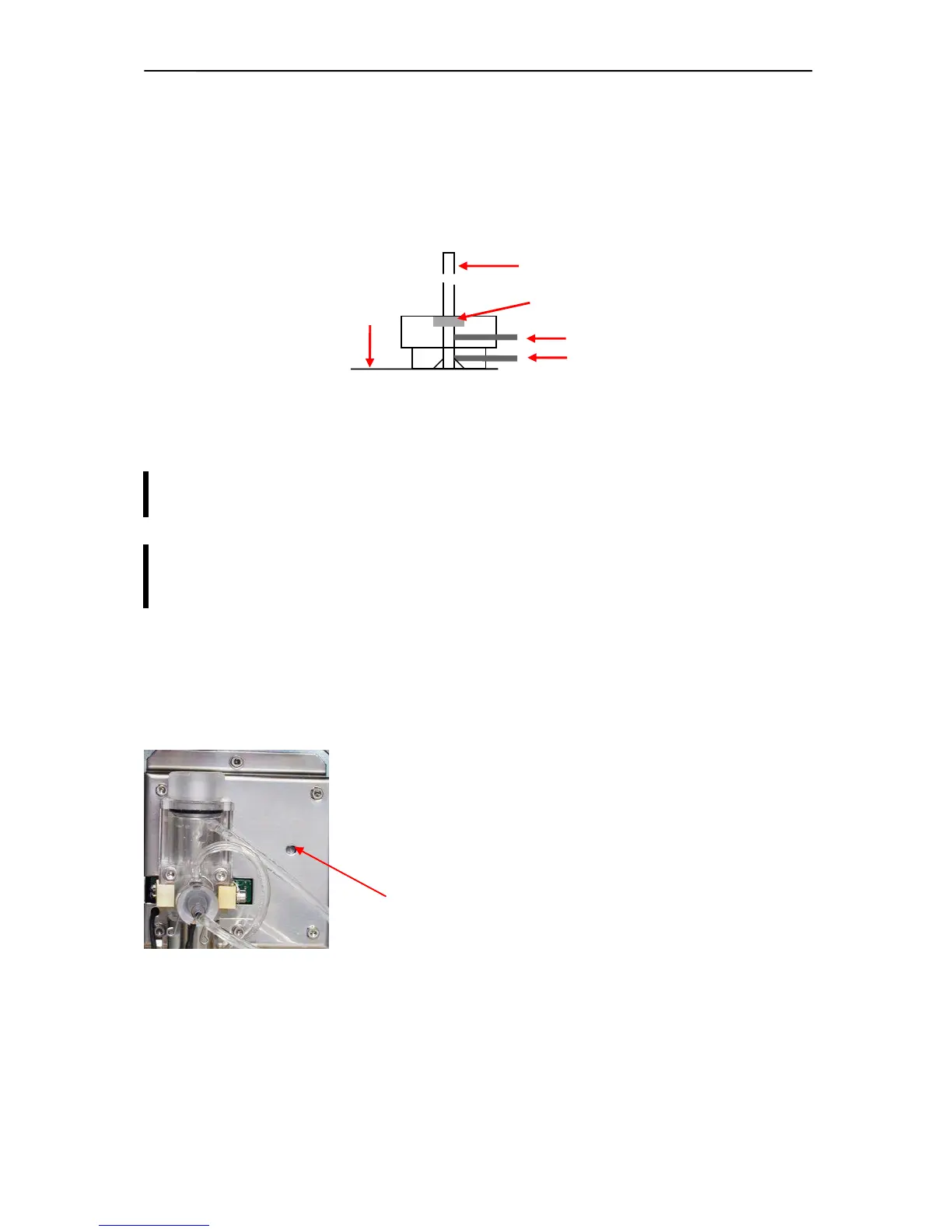

Check the setting of the needle. If end of the needle is at the bottom of the washing head,

needle is set correctly. If not, open screws “B” (see above), and adjust the needle to the bottom

of the washing head. Fasten “B” screws.

Set the end of the tip to the washing head’s bottom plane, while the carriage is held by

motors. (Needle setting menu). Fix the „B” screws.

Be careful with the bent upper end of the sampling needle, because if badly aligned,

during movement it can hit other mechanical components causing mechanical jam,

and therefore damages or error.

4.2. Hardware settings

4.2.1. Amplifier offset setting

Amplifier offset should be between ±5mV. Run self test to determine whether offset is within this

range. If it is out of range, it should be re-set, by the following way.

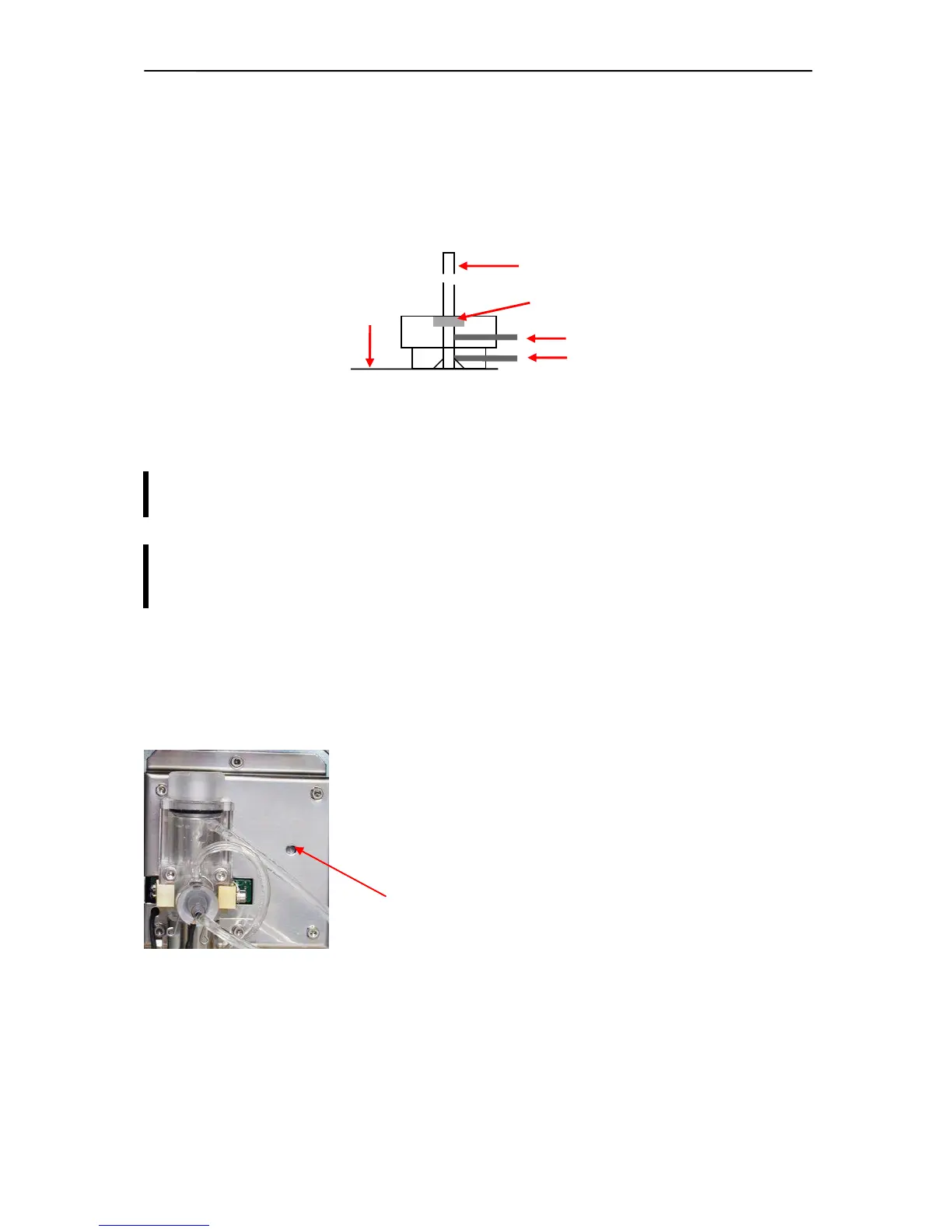

1. Locate the opening for offset setting potentiometer on the

measuring block (see enclosed picture).

2. In Service menu select Offset adjustment menu.

3. Adjust the potentiometer to reach 0 mV.

Opening for offset adjustment on measuring block

Loading...

Loading...