DOD Technologies, INC • 675 Industrial Dr. Bldg. A • Cary, IL 60013 • Phone (815) 788-5200 • Fax (815) 788-5300

Innovative Life Safety Systems & Services

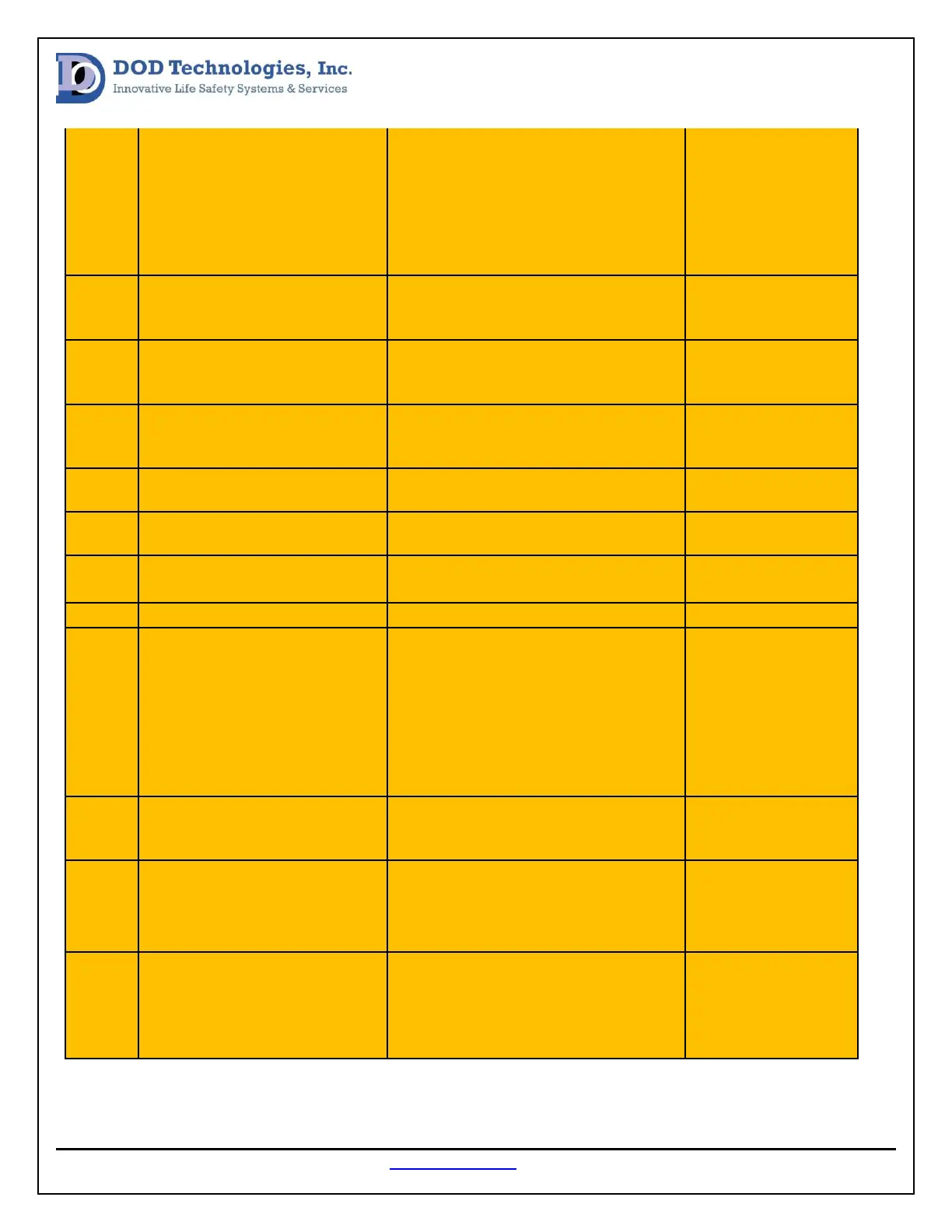

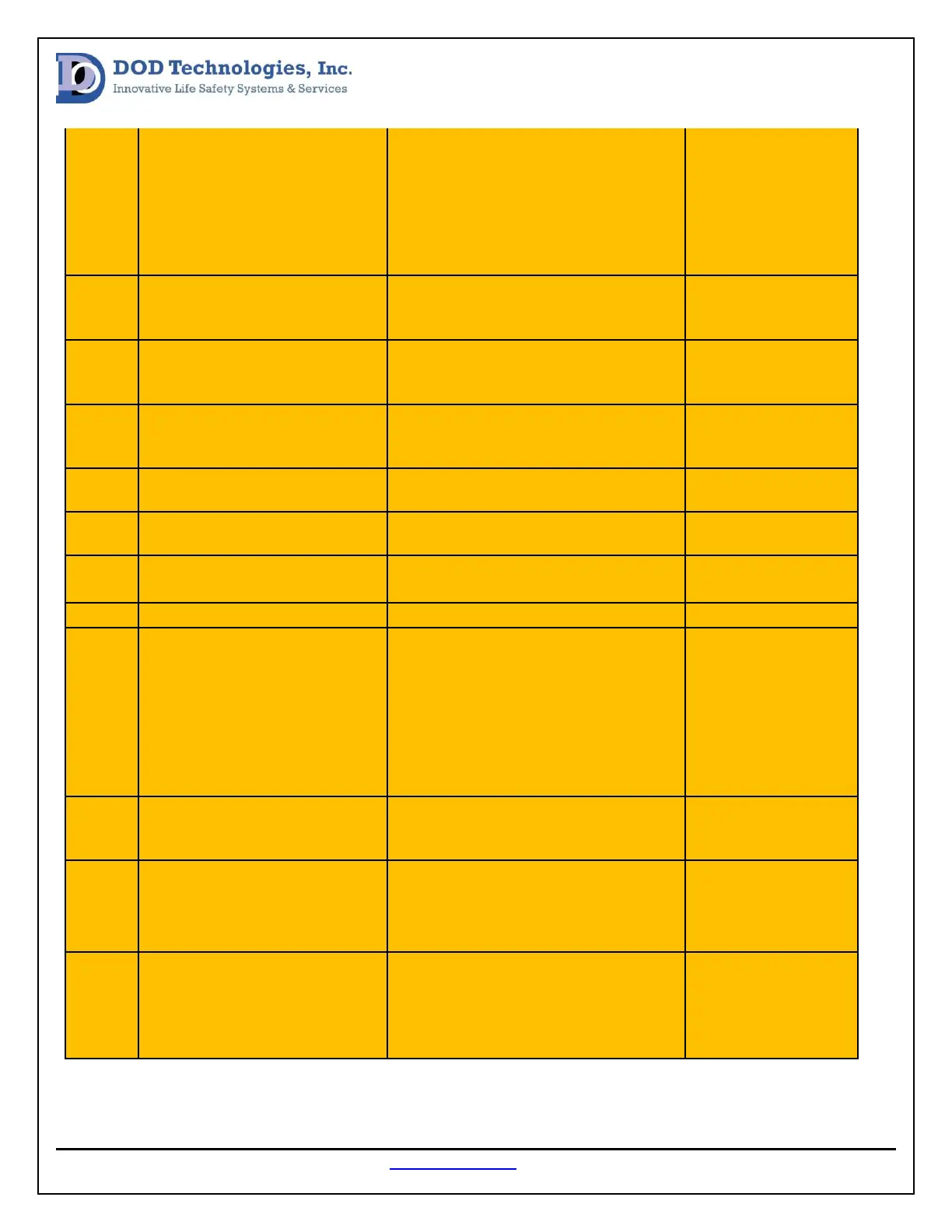

Low Flow - Verify Tray Insertion

The flow is low for multiple points on an

analyzer.

1. Verify analyzer is

fully inserted.

2. Make sure all

points are flow

balanced. 3.

Refer to Flow Path

verification procedure

Interruption during Modbus

communication process.

1. Power cycle unit

2. Contact DOD

Technologies, Inc.

Optic Block Comm. Failure

Communication interruption between

optic block and PC.

1. Refer to Optic

Troubleshooting

Procedure.

Communication interruption between

Flow board and PC.

1. Refer to Flow

Comm. Fault

Procedure.

Micro switch failed to open during a

tape advance.

1. Refer to Gate Fault

Procedure.

Micro switch failed to close during a

tape advance.

1. Refer to Gate Fault

Procedure.

Setting DAC to preset values

CL96 was unable to set DAC values back

to previously retained values.

Block Below Minimum Voltage

Optic block voltage dropped below the

required voltage of 5.1 V

1. Verify 5V supply is

turned up to 6.1 VDC

2. Verify all optic

blocks have at least

5.4 VDC

3. See Optic

Troubleshooting

Procedure

Output Module Failure or Not

Installed

Expected I/O module cannot be located

by the PC.

1. Refer to I/O

Verification

Procedure.

Retentive Memory Error, History

and/or Tape counters may be

corrupt.

Unable to load previous historical

events after power cycle.

CL96 was left out of analysis for a time

frame that overlapped the time out

setting.

1. Check to see if a

fault caused the CL96

to leave analysis

2. If not put the CL96

back into analysis

Loading...

Loading...