4302-067-G-2-21

24

3.3 Limit Sensors Adjustment Continued

6006 Limit Sensors ONLY

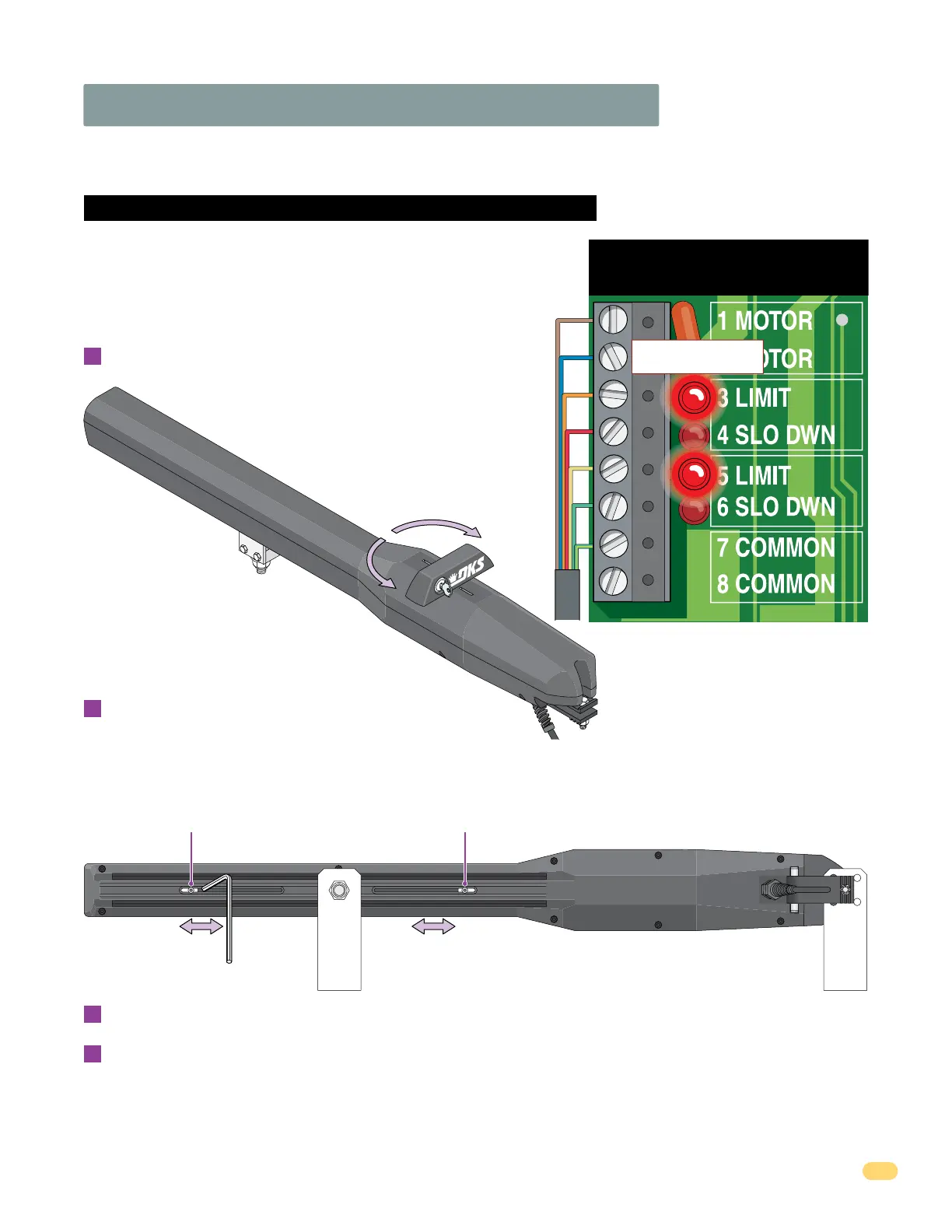

Manually move the gate to the desired open or closed position.

Loosen set screw and slowly slide the limit assembly.

SLOW DOWN LED will light first, continue sliding until the corresponding

LIMIT LED on the circuit board lights up. Tighten screw.

Manually move the gate to other position. Repeat process with the other

limit assembly.

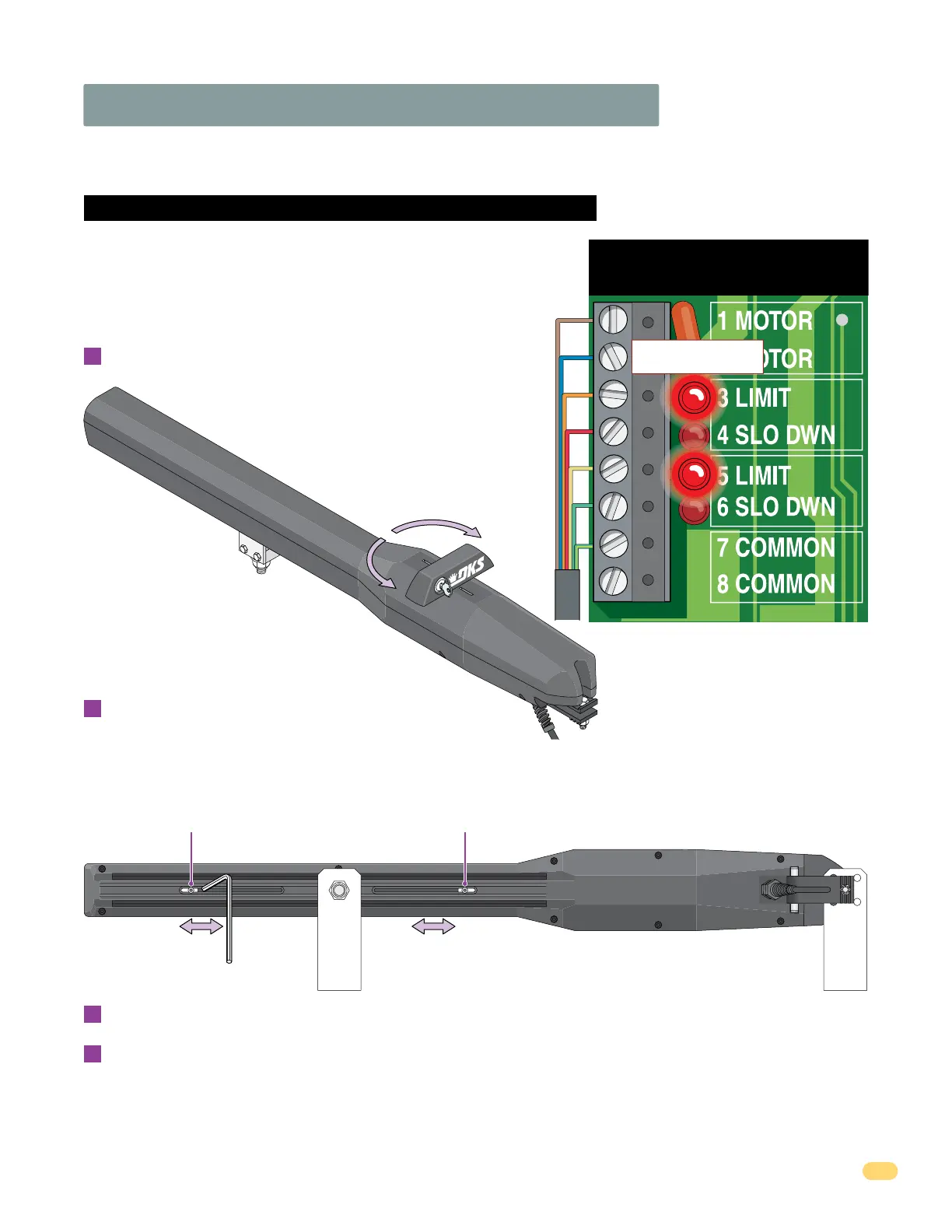

Manually unlock handle with key and rotate it 90°.

A

B

C

D

Power to the circuit board must be ON when adjusting the limit sensors.

Adjust the secondary actuator limit sensors if dual actuators have been installed. DIP-switch SW 1, switch 2 controls

secondary actuator opening direction. DIP-switch SW 1, switch 7 MUST be ON when using dual actuators (See page 20).

Rotate handle back 90° and re-lock it. Test the gate stopping positions. Re-adjust if necessary.

IMPORTANT: The operator MUST OPEN GATE upon initial power up and OPEN command.

If the operator closes gate after giving first open command, shut off power and reverse DIP-switch SW1, switch 1 setting

otherwise operator will NOT function correctly.

Set Screw

Hex Wrench

Bottom View

Set Screw

Note: 3 and 5 limit LEDs can be

Open or Close limits depending

on SW 1, switch 1 and 2 settings

(See page 19).

5 LIMIT 3 LIMIT

Limit LEDs

If factory wired jumpers are installed on

operator terminals, they must be

removed or operators will not function.

7-Wire

Operator

Cable

Handle

90°

Note: Handle can

be rotated 180° and

locked facing either

side of operator for

easy key access.

Rotate handle 90°

in either direction to

release carriage.

Loading...

Loading...