G424F(FE) Service Manual Chapter 3. Engine Mechanical System 73

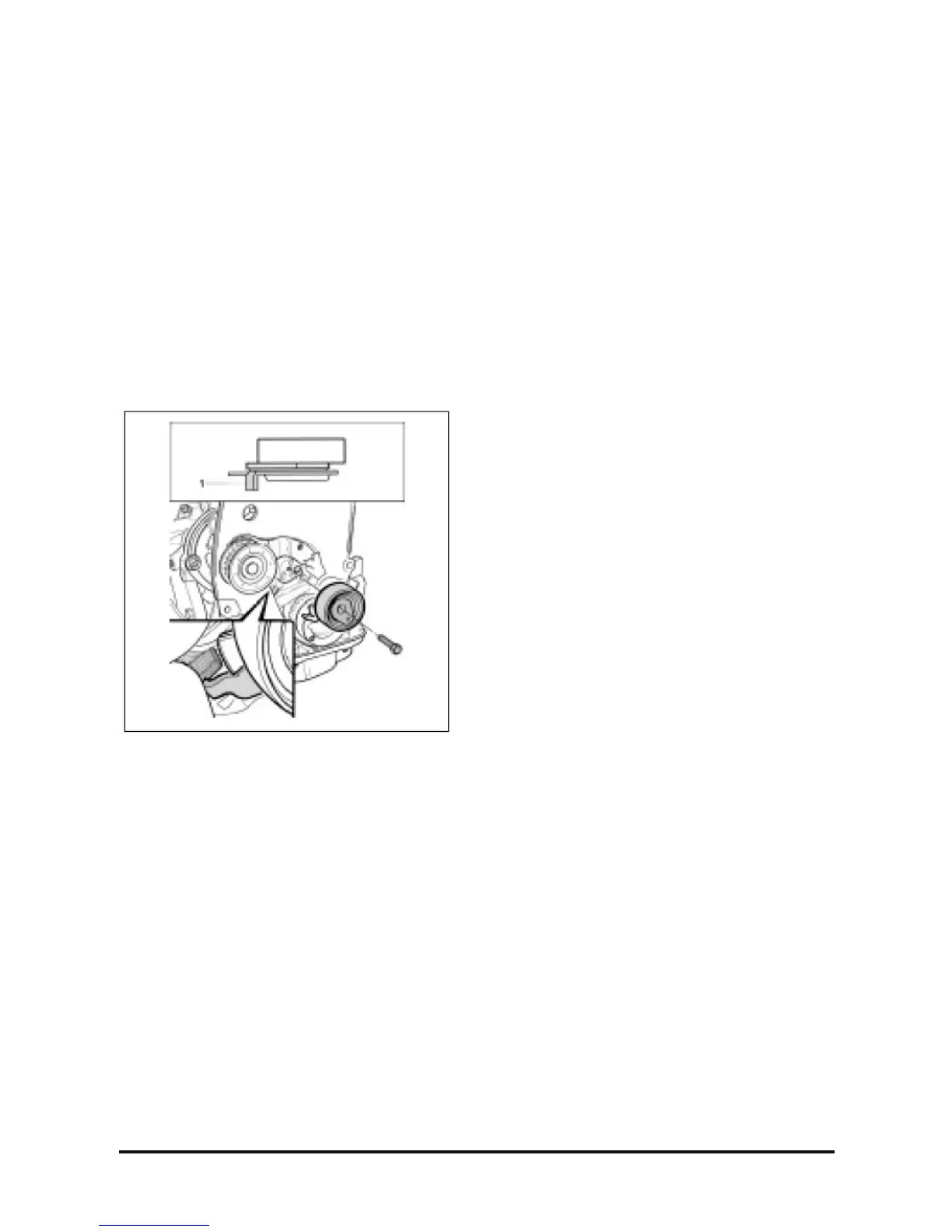

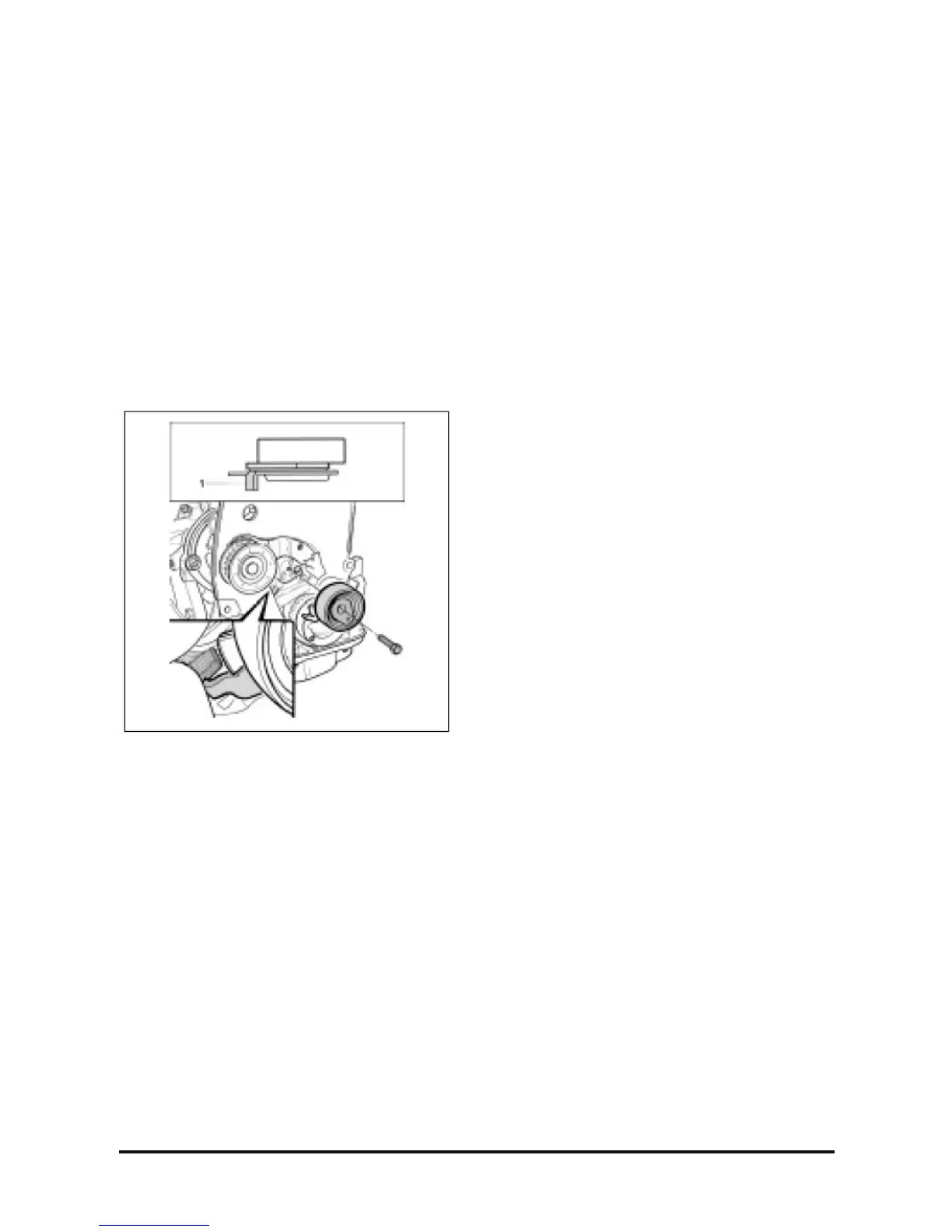

Important

• The Tensioner roller lug (1) should be positioned

in the guide housing (2) of the oil pump case.

12. Crankshaft timing pulley and attaching bolt,

without tightening.

13. With a 17-mm socket and torque wrench.

Tighten

• Bolts: 135 + 30° + 15° (99 lb·ft. + 30° + 15°).

14. Timing pulley rear cover; see “Timing Pulley

Rear Cover – Installation”, in this section.

Oil Pump Assembly

Disassemble

1. Remove the oil pump; see “Oil Pump – Removal”,

in this section.

2. Pump cover, with a proper posi-drive screwdriver.

3. Drive gear.

4. Driven gear.

5. Oil pressure switch, with a 26-mm wrench.

6. Oil filter gallery plug, with a 19-mm combination

wrench.

7. Relief valve plug, with a 24-mm combination

wrench.

8. Sealing washer.

9. Spring.

10. Valve plunger.

Clean

• All pump parts.

Inspect

• Parts for wear.

Measure

Play between the following parts:

• Driven gear and case, which should be 0.11 –

0.19 mm.

• Drive gear and crescent, which should be 0.35 –

0.45 mm.

• Gear and cover, which should be 0.03 – 0.10

mm.

Assemble

1. Plunger in the valve. (1)

2. Spring. (2)

3. Sealing washer. (3)

4. Relief valve plug, with a 24-mm socket wrench

and torque wrench.(4)

Tighten

• Valve plug: 45 – 60 N•m (33 – 44 lb•ft).

5. Driven gear. (5)

6. Drive gear. (6)

7. Oil pump cover and attaching screws, with a posi-

drive screwdriver. (7)

8. Oil pump gallery plug, with a torque wrench. (8)

Tighten

• Gallery plug: 30 – 35 (22 – 25,7 lb·ft)

9. Oil pressure switch, with a 26-mm socket and

torque wrench.

Loading...

Loading...