G424F(FE) Service Manual Chapter 3. Engine Mechanical System 85

Important:

• Whenever the crankshaft is removed, it should

be positioned standing up in the flywheel, to

prevent it from warping.

Engine Assembly

Installation

Install or connect

1. Upper shells in the block; lubricate the surface

turned toward the saddle with engine oil.

2. Crankshaft in the cylinder block.

3. Main bearing caps with the shells lubricated on

the surfaces turned to the saddle.

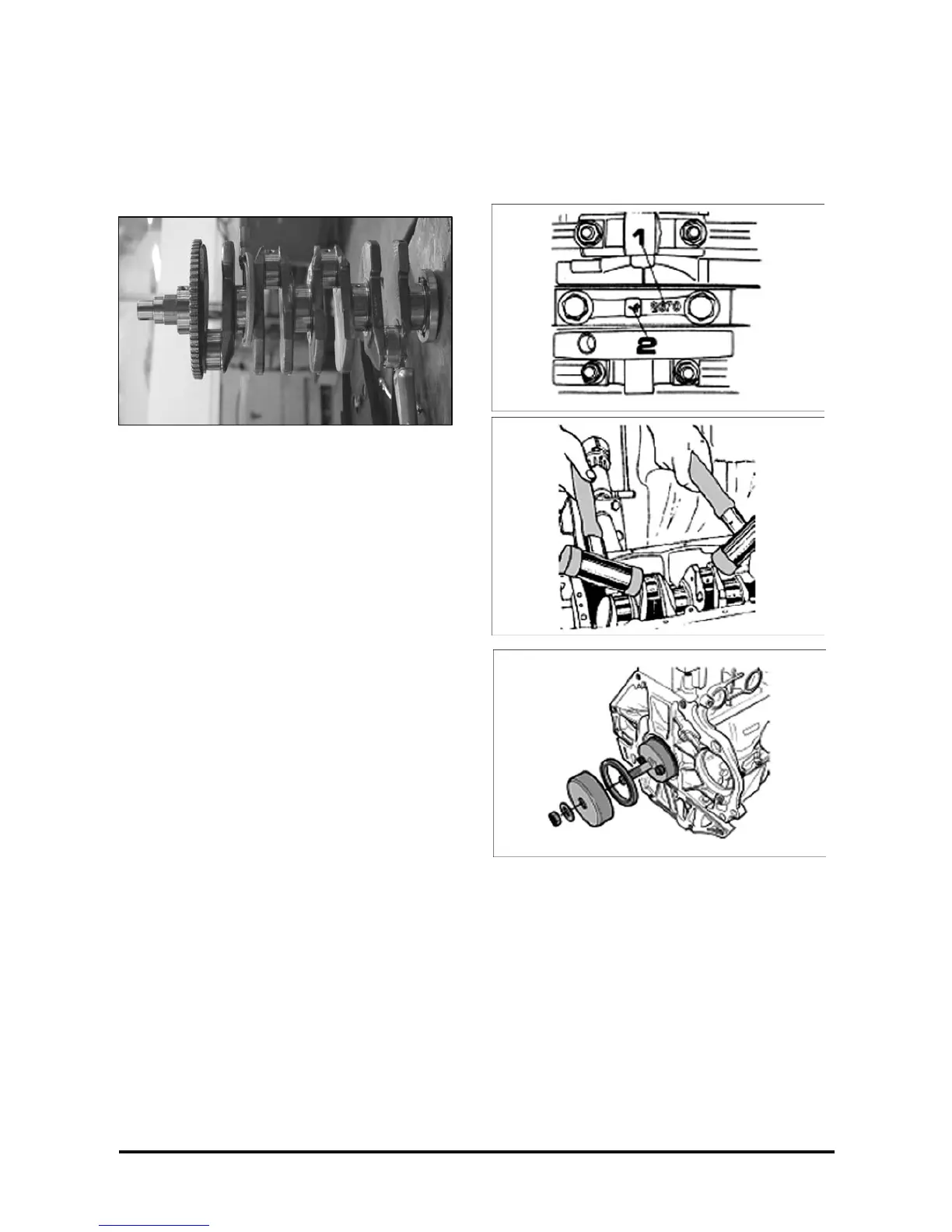

Important

• The bearing caps should be installed so that the

cast number bases (1) stay turned to the engine

rear side. Pay also attention to the engraved

sequence numbers (2).

• Fill the rear bearing cap side grooves with

sealant.

4. Main bearing attaching bolts, without tightening,

with a Torx E12 wrench, extension and handle.

Important

• With a plastic mallet, slightly tap the crankshaft,

on both directions, so as to mainly seat the

thrust bearing rear face.

5. Tighten the main bearing attaching bolts with a

Torx E12 wrench, extension and torque wrench.

Tighten

• Bolts: 50 N·m + 45° + 15°.

6. Crankshaft seal, with tool KM-658.

7. Piston-connecting rod assembly in block, with the

aid of the universal band, position the piston arrow

turned toward the front end of the engine.

Important

• Lubricate the rings and cylinders.

• Simultaneously, guide the connecting rod

bearing with tool T-9806681.

• Install the connecting rod upper shell lubricated

only in the face turned to the bearing journal

and pull the connecting rod until it touches the

journal.

Loading...

Loading...