G424F(FE) Service Manual Chapter 3. Engine Mechanical System 94

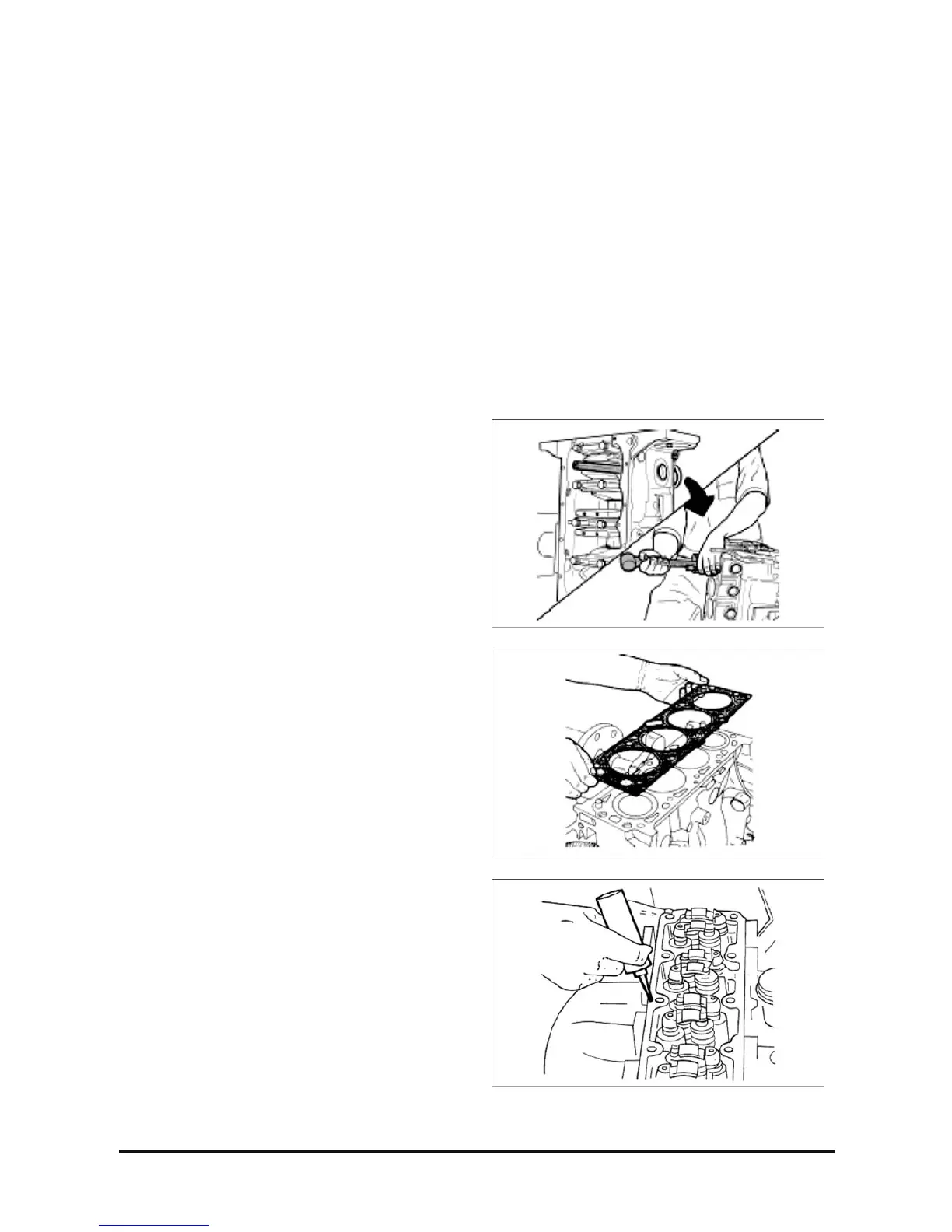

9. Connecting rod cap bolts, without fully tightening,

with a 14-mm socket wrench and handle.

Important

• Rotate the crankshaft some turns, so that the

connecting rods are properly seated.

10. Tighten the connecting rod cap bolts, with a 14-

mm socket wrench and torque wrench.

Tighten

• Connecting rod cap bolts:...............30 – 40 N·m

(22.0 – 29.5 lb·ft.)

+ 40° to 45°.

11. A new gasket in the oil pump.

12. Oil pump to cylinder block and attaching bolts,

with a 5-mm Allen wrench and torque wrench.

Tighten

• Bolts: 4 – 10 N·m (3 – 7 lb·ft.).

13. Balancer and baffle plate and attaching bolts,

with a Torx E12 wrench and torque wrench.

Tighten

• Bolts: 20 – 24 N·m (15 – 17.6 lb·ft.).

Obs.: One of the bolts only can be installed and

tightened after installing the oil strainer.

14. Oil strainer and attaching bolts in the oil pump,

with a 10-mm socket wrench and torque wrench;

tighten.

Tighten

• Bolt: 4 – 10 N·m (3 – 7 lb·ft.).

15. Adhesive sealant in the cylinder block and install

the crankcase and attaching bolts; tighten with a

Torx E12 wrench and torque wrench.

Tighten

• Bolts: 6 – 10 N·m (4.5 – 7 lb·ft.).

16. Oil filter.

Obs.: Only tighten with your hands.

17. Turn tool M-780668 180°, so that the engine

stay with the pistons turned upward.

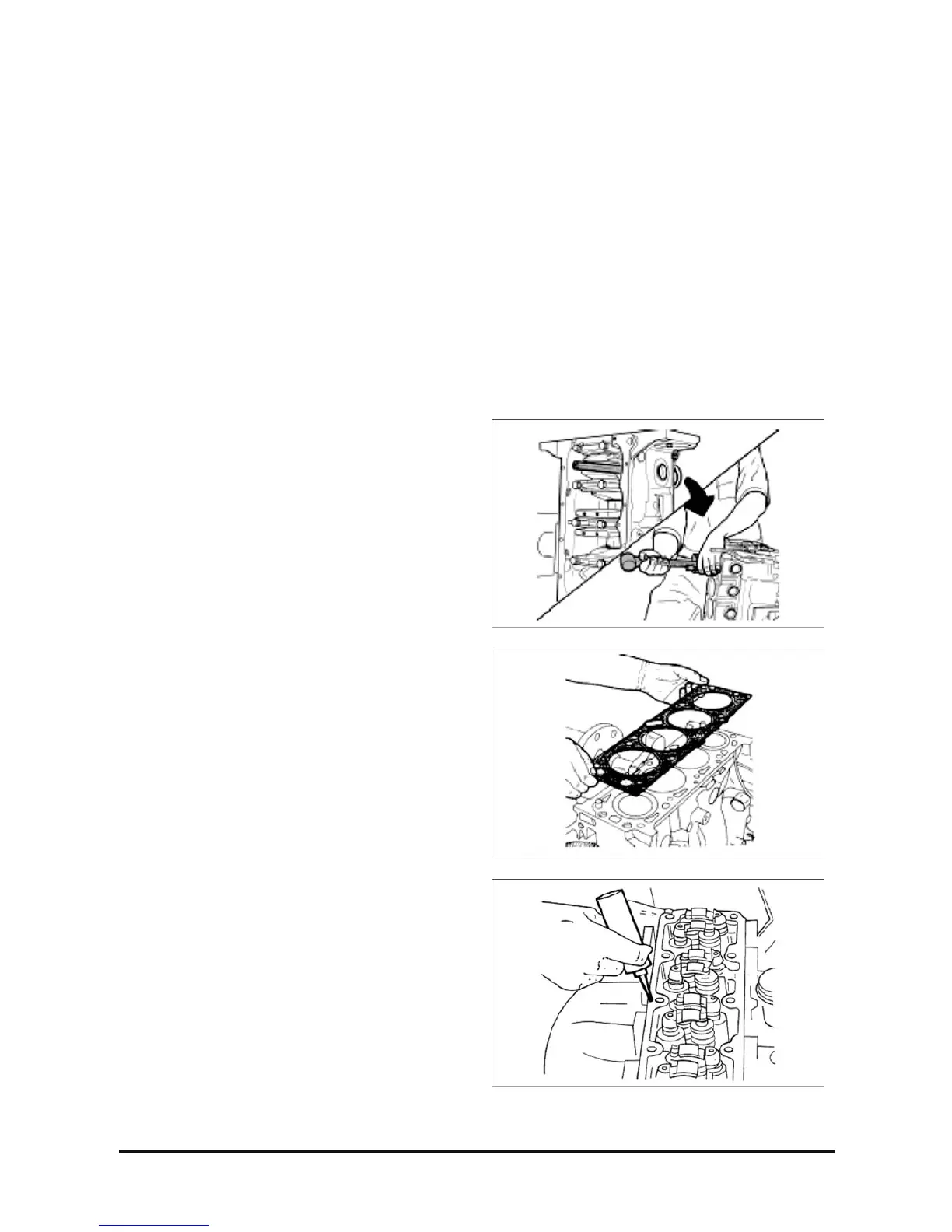

18. A new cylinder head gasket, with the TOP mark

turned upward and toward the engine front side.

Obs.: Whenever is necessary to remove the

cylinder head, a new gasket should be used.

19. Cylinder head in the engine.

20. Valve lifters, linkages and rocker arms,

lubricated with molybdenum bisulfate compound.

Important

• Apply sealing compound in the surface where

the camshaft case will be seated.

21. Camshaft case.

Loading...

Loading...