G424F(FE) Service Manual Chapter 3. Engine Mechanical System 96

Tighten

• Bolts: 4 – 10 N·m (3 – 7 lb·ft.).

38. Timing belt.

Important

• Timing pulley, keeping stretched the side

opposite to the water pump, observing the

engine RPM direction, if using the same belt.

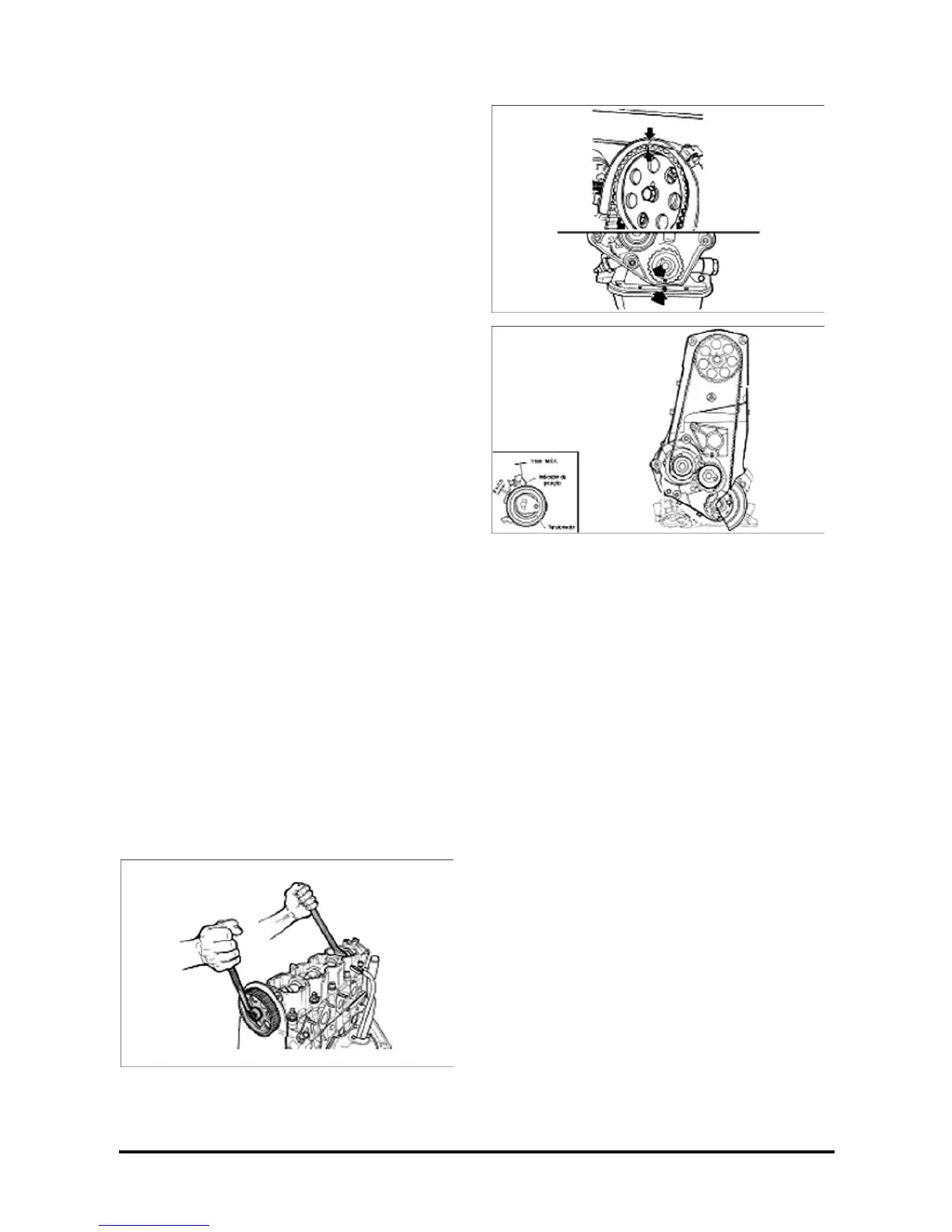

• Align the camshaft timing pulley mark with the

timing pulley rear cover mark.

• Align the crankshaft timing pulley mark with the

oil pump case flange mark, on the no. 1 cylinder

combustion stroke.

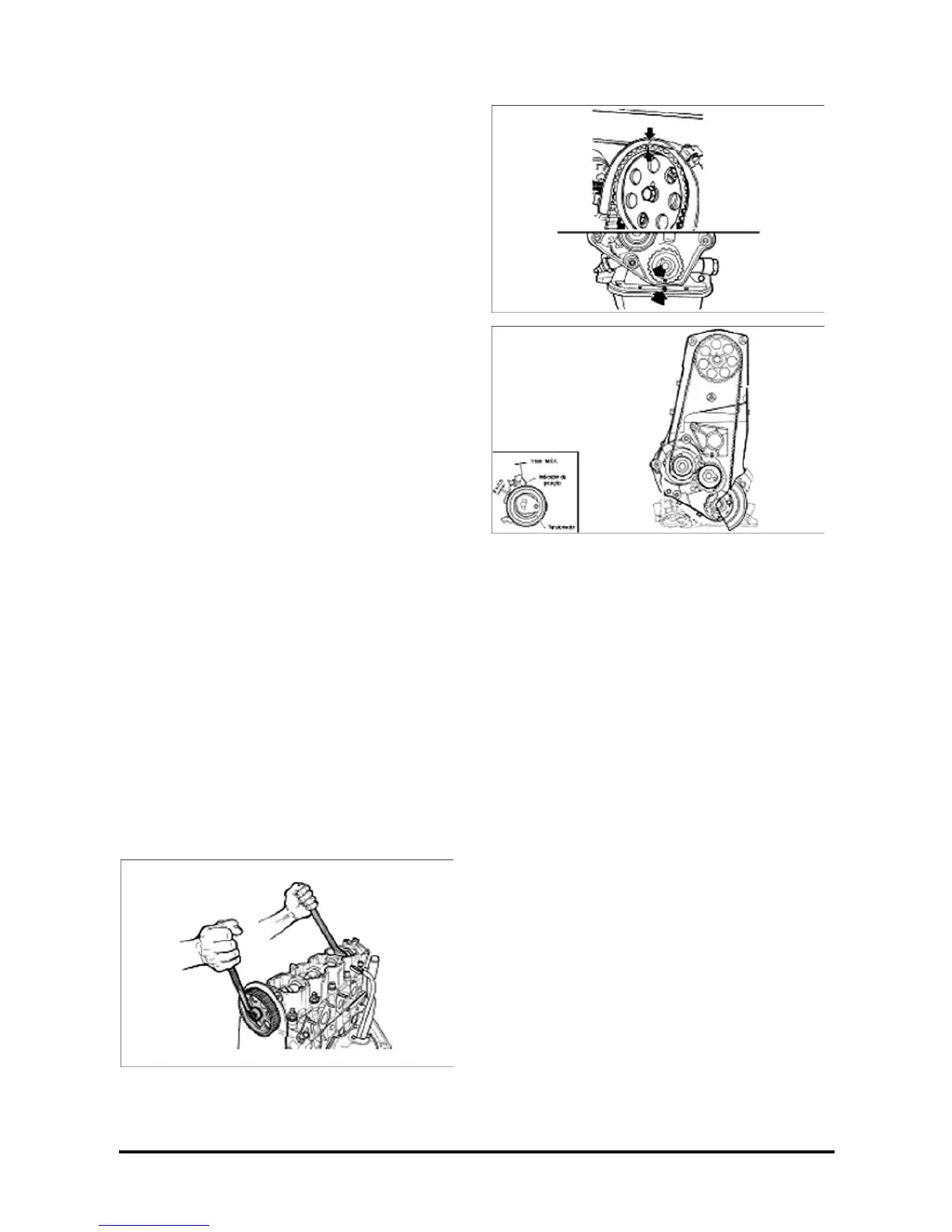

• Adjust the belt Tensioner; with a 6-mm Allen

wrench, so as to keep steady the Tensioner

shaft, loosen the Tensioner shaft attaching bolt,

use a 13-mm combination wrench until it

remains steady.

With a 6-mm Allen wrench, turn counterclockwise

the Tensioner shaft up to the NEW marking point (±

1 mm) (detail B). The needle can move from the

right side up to the final adjusting position. Tighten

the bolt with a 13-mm combination wrench; for old

timing belts, follow the same procedure, but

adjusting the belt in the “USED” position.

This change is suggested due to the old belt

presenting a different course of action regarding the

new belt.

39. Timing belt front cover and attaching bolts, with

a 10-mm socket wrench and torque wrench.

Tighten

• Bolts: 6 – 8 N·m (4.4 – 5.8 lb·ft.).

40. A new gasket in the intake manifold.

41. Intake manifold in the cylinder head and

attaching nuts, with a 13-mm socket wrench,

extension and torque wrench.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.).

42. A new gasket in the exhaust manifold.

43. Exhaust manifold in the cylinder head and

attaching nuts; use a 13-mm socket wrench,

extension and torque wrench.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.)

44. A new “O” rings in the crankcase breather tube.

45. Crankcase breather tube and oil dipstick tube in

the cylinder block and attaching bolts, with a 13-

mm socket wrench and torque wrench.

Tighten

• Bolts: 20 – 30 N·m (15 – 22 lb·ft.).

46. Crankcase breather tube-to-valve covers hose,

with clamp pliers; attach the same.

Loading...

Loading...