14. Distance between hook and needle

Caution: Danger of injury !

Switchthemainswitchoff.

Adjust the needle protection only with the machine switched off.

Standard checking

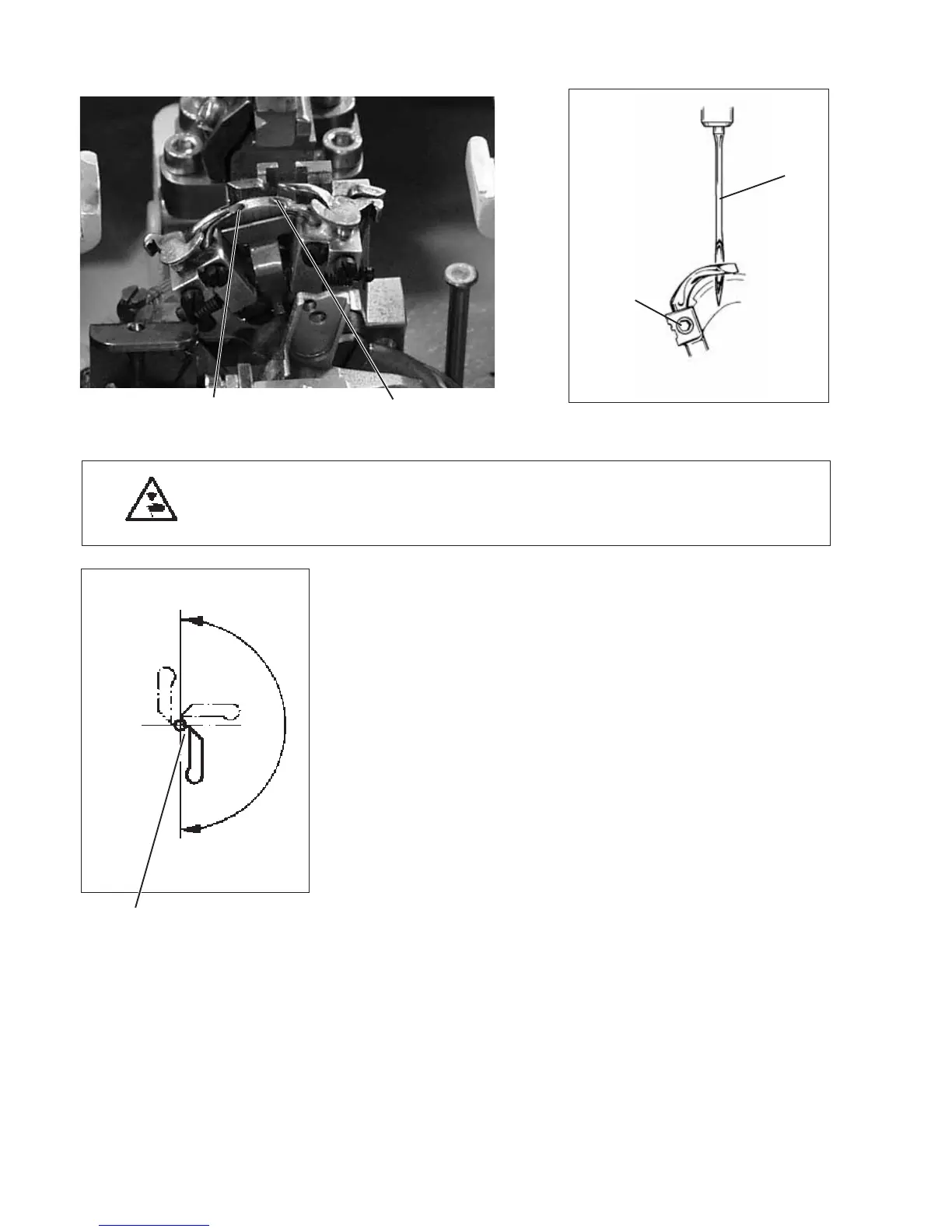

The hook tips 1 and 4 should be in a distance of max. 0.1 mm to the

needle 3. The distance between hook and needle should be equal

during the whole rotary motion of the hook support.

–

Turn the handwheel until the left hook tip is at the level of the

middle of the needle. Check the distance between needle and hook

tip in the following positions.

1. Hook tip basic position

2. Hook support manually turned by 90°

3. Hook support manually turned by 180°

If the distance between hook tip and needle is different in the three

positions, first align the rotary centres of needle bar and hook support.

Correction

–

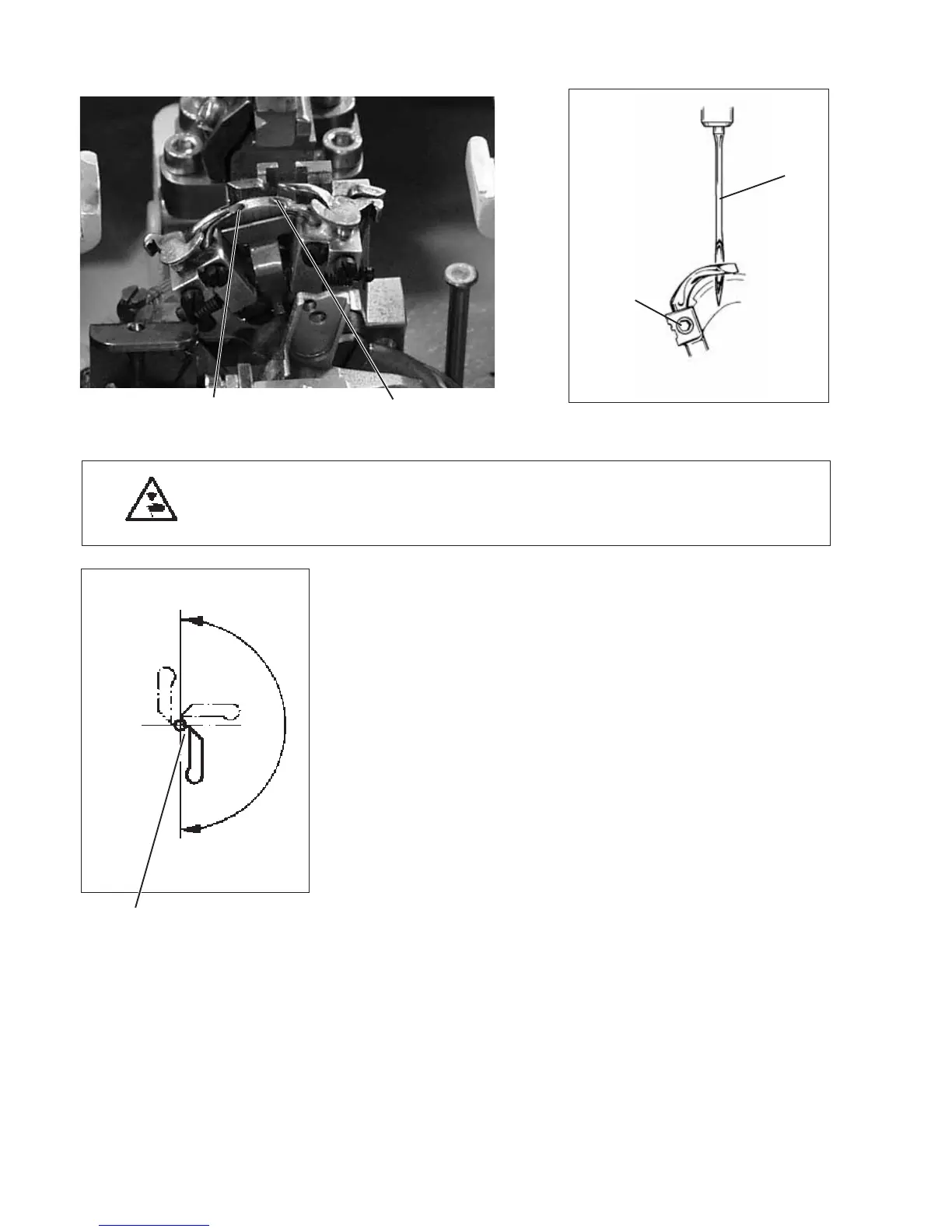

Loosen screw 2 at the corresponding hook.

–

Set the distance between hook and needle accordingly.

–

Tighten screws 2.

38

2

3

0,1 mm

41

Loading...

Loading...